Reverse osmosis membrane, and preparation method and application thereof

A technology of reverse osmosis membrane and cross-linking reaction, which is applied in the field of separation membrane, can solve the problems of poor desalination rate and water permeability, and achieve the effect of simple preparation method, excellent desalination rate and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

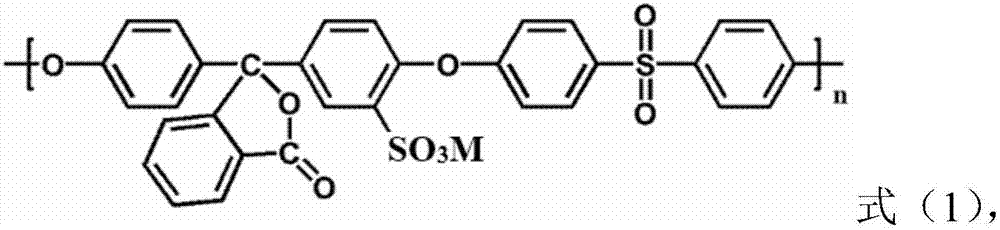

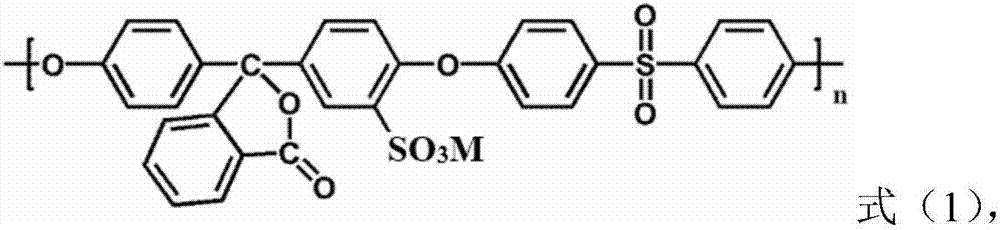

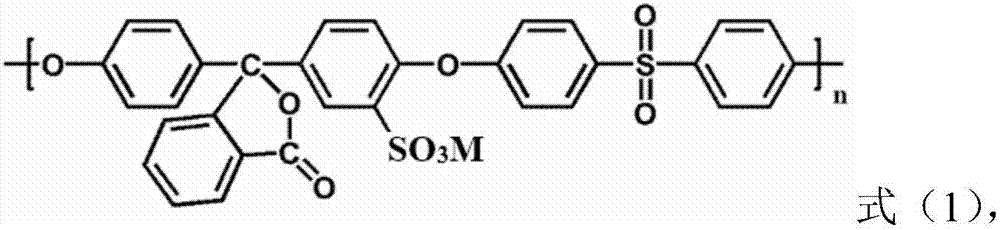

[0030] The preparation method of the reverse osmosis membrane provided by the present invention comprises sequentially forming a separation layer, an intermediate connection layer and a crosslinking layer on a support layer, the separation layer is formed by sulfonated polyarylether sulfone represented by formula (1), and the The middle connecting layer is formed of polyethylene glycol, and the cross-linked layer is formed of cross-linked alginate;

[0031]

[0032] Wherein, M is K, Na or Li, and n is 10-100; preferably, M is Na, and n is 25-75.

[0033]The present invention has no special limitation on the thickness of the support layer, separation layer, intermediate connection layer and crosslinking layer, which can be a conventional choice in this field, but in order to make these four layers play a better synergistic effect, making The obtained reverse osmosis membrane has better desalination rate, water permeability and chlorine resistance, preferably, the thickness o...

Embodiment 1

[0066] The method of dip coating is applied on the surface of the separation layer of the reverse osmosis membrane M1 obtained in Comparative Example 1 to coat a layer of 1 wt% polyethylene glycol (number average molecular weight is 10000) aqueous solution, after drying at 80° C. for 10 min, to obtain The modified initial membrane includes a support layer, a separation layer and an intermediate connection layer stacked in sequence. Then 1.0g sodium alginate (the number average molecular weight is 60000) and 0.1g glutaraldehyde are dissolved in 100g deionized water, and the dilute hydrochloric acid of 1mol / L is dripped under stirring, and the pH value of adjustment solution is 2, then at normal temperature After stirring for 24 hours, a clear coating solution was obtained by filtration. Coating the coating solution on the surface of the intermediate connection layer of the prepared modified initial membrane, and then heating at 100°C for 10 minutes to obtain a reverse osmosis m...

Embodiment 2

[0068] The method of dip coating is applied on the surface of the separation layer of the reverse osmosis membrane M3 obtained in Comparative Example 3 to coat a layer of 2.5% by weight polyethylene glycol (number average molecular weight is 6000) in aqueous solution, after drying at 60°C for 20min, to obtain The modified initial membrane includes a support layer, a separation layer and an intermediate connection layer stacked in sequence. Then 1.0g sodium alginate (the number-average molecular weight is 85000) and 0.1g glutaraldehyde are dissolved in 100g deionized water, and the dilute hydrochloric acid of 1mol / L is dripped under stirring, and the pH value of adjusting solution is 2, then at normal temperature After stirring for 24 hours, a clear coating solution was obtained by filtration. Coating the coating solution on the surface of the intermediate connection layer of the prepared modified initial membrane, and then heating at 120°C for 2 minutes to obtain a reverse osm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com