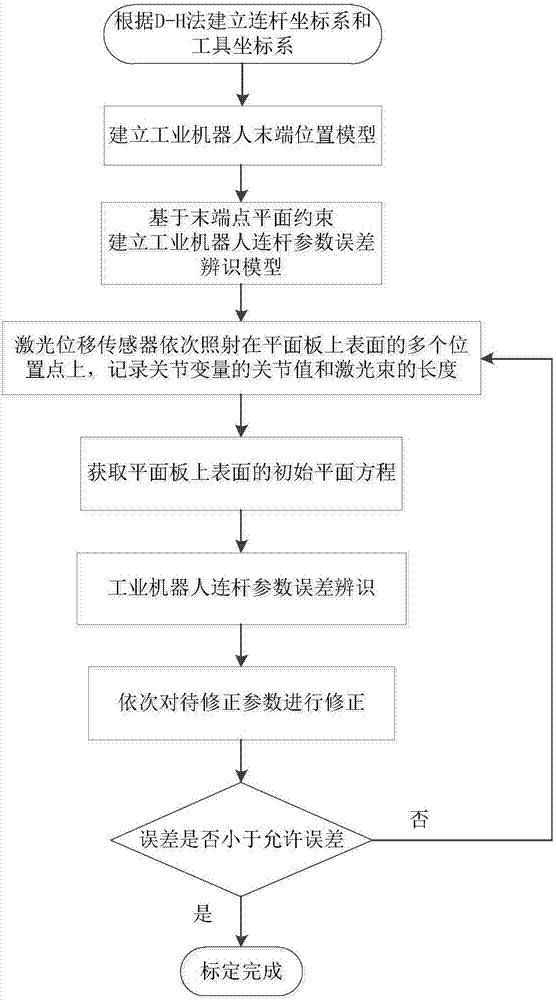

Calibration method of connecting rod parameters of industrial robot based on end-point plane constraint

An industrial robot, plane constraint technology, applied in manipulators, manufacturing tools, etc., can solve the problems of low degree of automation, low operability, low precision, etc., to reduce production costs, avoid low absolute positioning accuracy, kinematic model precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

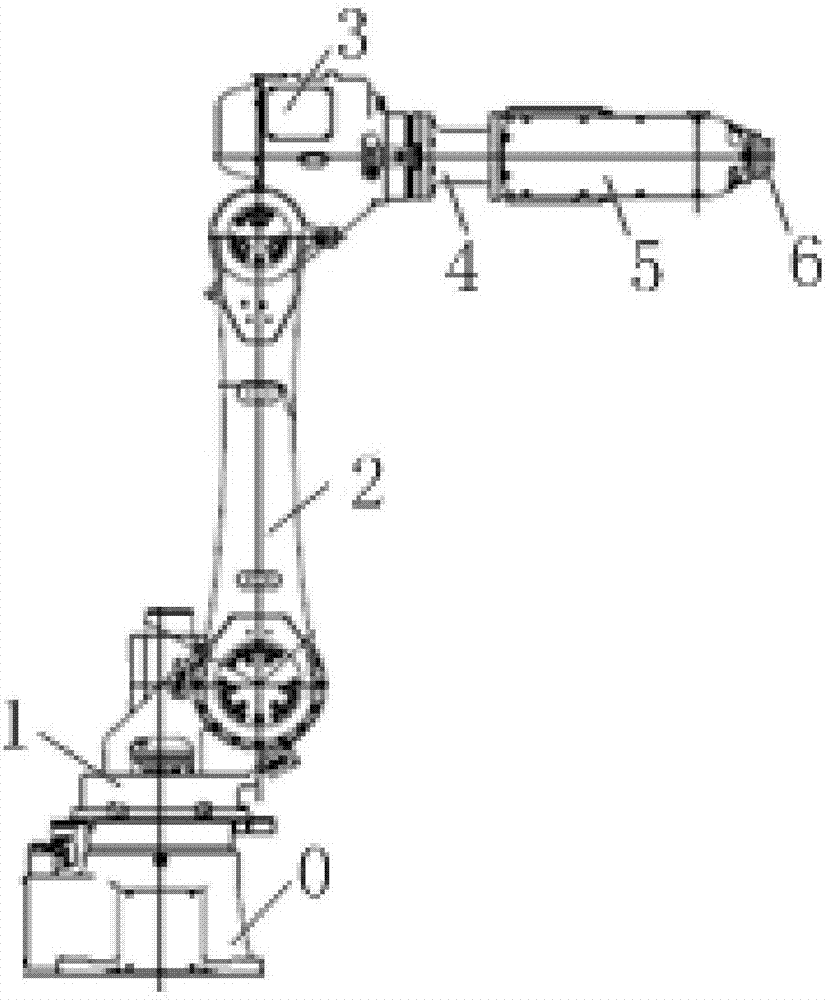

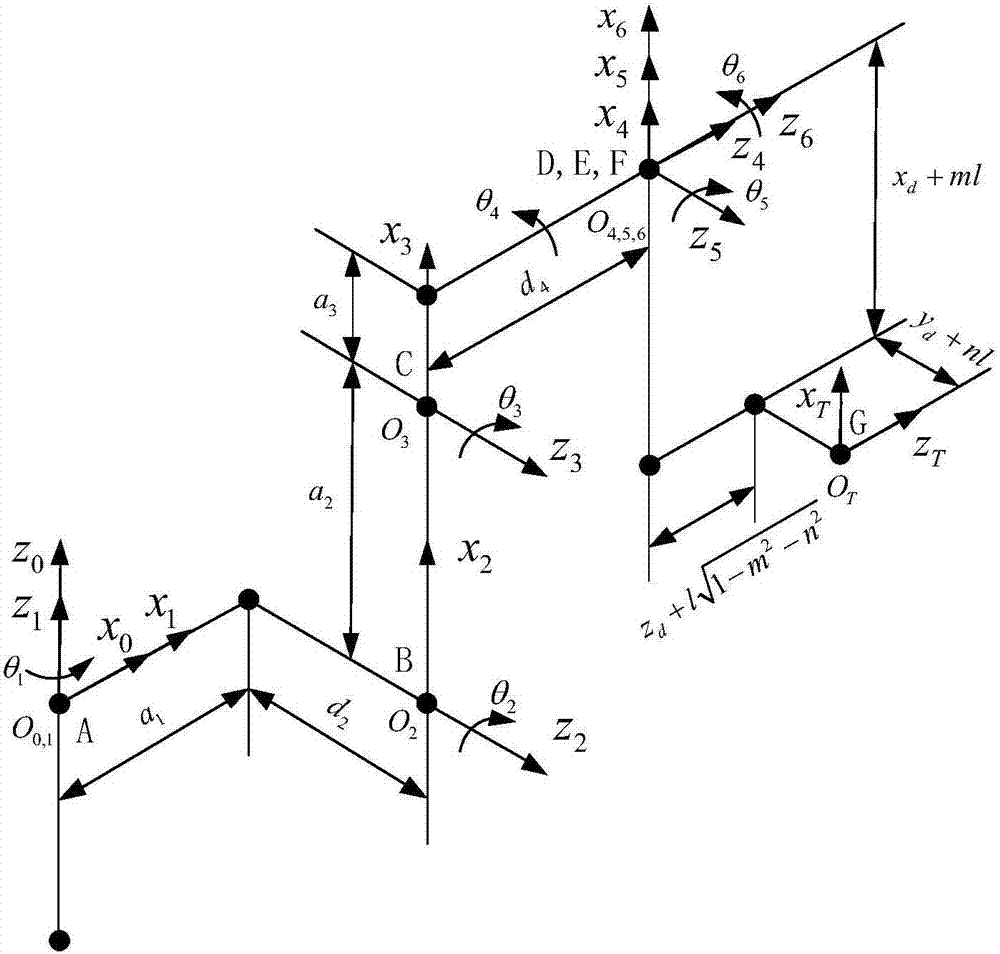

[0086] This embodiment takes Huazhong CNC 6012 industrial robot as an example, and its configuration is as follows figure 2 As shown, the Huazhong CNC 6012 industrial robot is an articulated robot, which consists of 6 revolving joints ( image 3 The points A, B, C, D, E, F shown) and 6 connecting rods ( figure 2 The 0-6 are connecting rod 0, connecting rod one, connecting rod two, connecting rod three, connecting rod four, connecting rod five, connecting rod six, connecting rod one to connecting rod six correspond image 3 The line segments AB, BC, CD, DE, EF, FG), the base is fixed and called link 0, the first joint connects the base and the first link, and the second joint connects the first link and the second The connecting rod, and so on, the tool is fixed to the connecting rod 6, and its connecting rod parameter calibration includes the following steps:

[0087] Step 1): According to the structural characteristics of the Huazhong CNC 6012 industrial robot and the DH method,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com