Medical textile material, and preparation method and application thereof

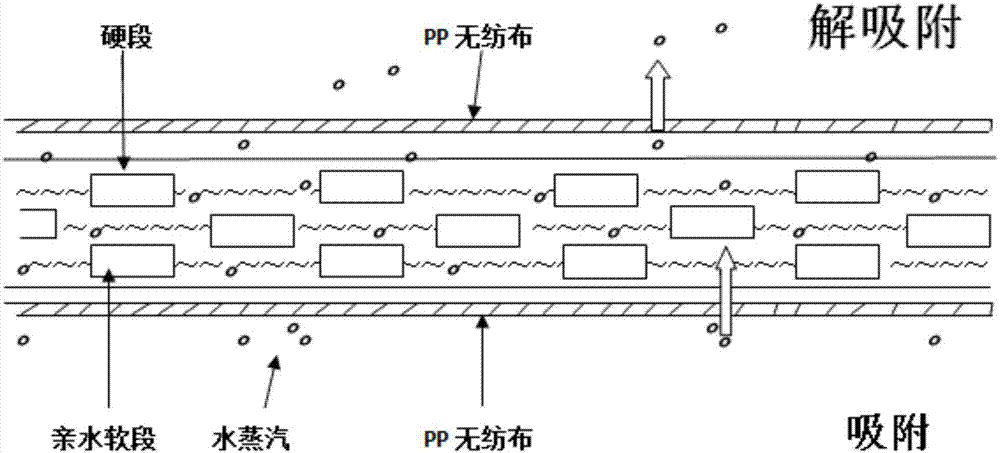

A textile and medical technology, applied in the field of medical textile materials and their preparation, can solve the problems that human sweat and moisture cannot be discharged, have no moisture perspiration, no moisture permeability, etc. Dry and comfortable, solve the effect of damp and sultry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

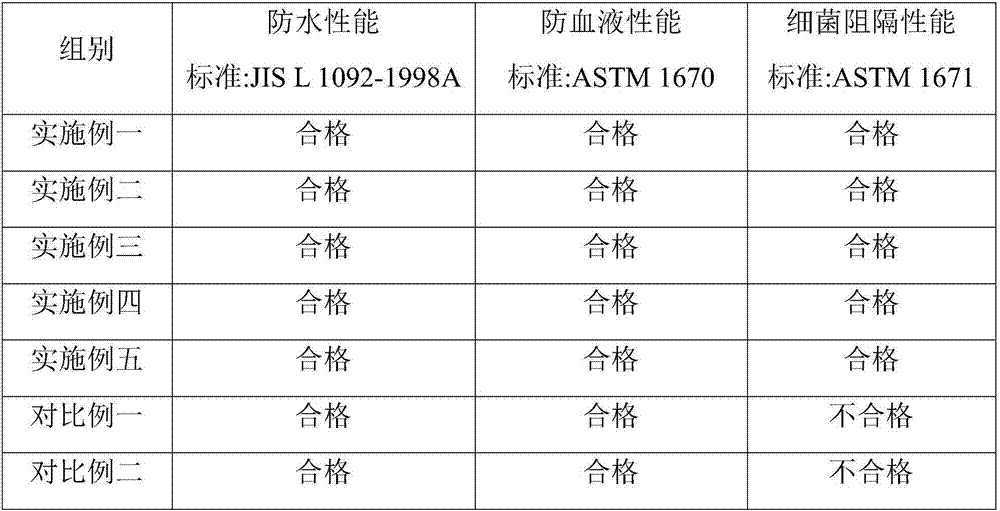

Examples

preparation example Construction

[0030] Preferably, the adhesive in steps S1 and S3 also includes chlorinated polyethylene and polyacrylate substances; the mass ratio of polyurethane hot melt adhesive, chlorinated polyethylene and polyacrylate substances is 1:(0.05~0.1 ): (0.1~0.2); the preparation method of polyacrylate material comprises the following steps: water, hydroxyethyl acrylate and diallyl dimethyl ammonium chloride are mixed with (40~50):1:(20~ 30) and mix the mass ratio evenly, then heat up to 68-70°C, and adjust the pH value to 5.4-5.6; add the initiator dibenzoyl peroxide, keep warm for 10-15 minutes, then continue to heat up to 90-92°C, And adjust the pH value to 7.3~7.5, then drop methyl acrylate and butyl methacrylate respectively, the mass ratio of initiator, methyl acrylate, butyl methacrylate and hydroxyethyl acrylate is (0.2~0.3): (20-30): (6-8): 1; keep warm for 2-2.5 hours after the dropwise addition to obtain polyacrylate substances.

[0031] Preferably, the polypropylene non-woven f...

Embodiment 1

[0034] This embodiment provides a medical textile material, comprising three layers, successively from top to bottom a polypropylene non-woven fabric layer, a thermoplastic elastomer film layer and a polypropylene non-woven fabric layer; wherein, the thickness of the thermoplastic elastomer film layer is 0.01mm.

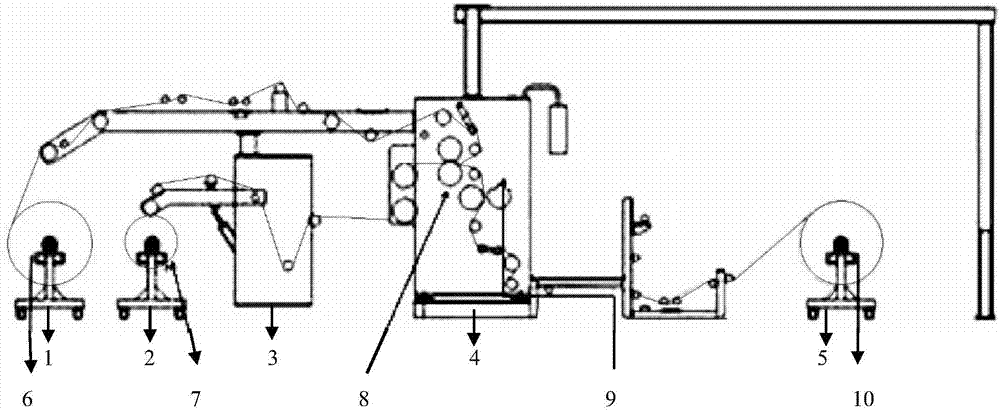

[0035] The medical textile material is prepared by a polyurethane hot-melt adhesive compound machine, which specifically includes the following steps:

[0036] S1: Place the thermoplastic elastomer film (TPE) coil at the first station, press the figure 2 The stroke shown pulls the film to the pressing roller of the fourth station; places the polypropylene (PP) non-woven fabric roll at the fifth station, press the attached figure 2 The stroke shown draws the PP non-woven fabric to the position of the scraping die head; scrapes or sprays the molten adhesive on the raised surface of the PP non-woven fabric; where the adhesive is polyurethane hot-melt adhesive.

[0037...

Embodiment 2

[0041] This embodiment provides a medical textile material, comprising three layers, successively from top to bottom a polypropylene non-woven fabric layer, a thermoplastic elastomer film layer and a polypropylene non-woven fabric layer; wherein, the thickness of the thermoplastic elastomer film layer is 0.01mm.

[0042] The medical textile material is prepared by a polyurethane hot-melt adhesive compound machine, which specifically includes the following steps:

[0043] S1: Place the thermoplastic elastomer film (TPE) coil at the first station, press the figure 2 The stroke shown pulls the film to the pressing roller of the fourth station; places the polypropylene (PP) non-woven fabric roll at the fifth station, press the attached figure 2 The stroke shown draws the PP non-woven fabric to the position of the scraping die head; scrapes or sprays the molten adhesive on the raised surface of the PP non-woven fabric; among them, the adhesive is polyurethane hot melt adhesive, ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com