Modular sewage treatment system

A sewage treatment system, modular technology, applied in the direction of oxidized water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve ground digging maintenance, production inconvenience, underground pipeline blockage, etc. problems, to achieve the effect of increasing flow rate, facilitating cleaning operation and promoting reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

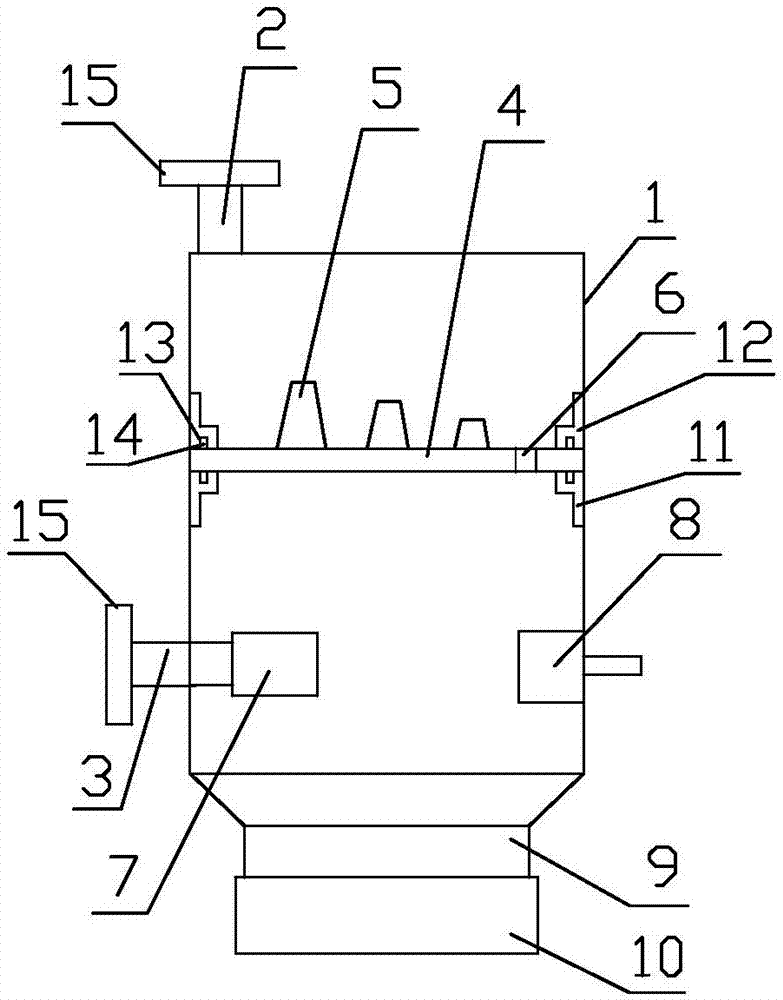

[0031] Such as figure 1 with figure 2 As shown, the modular sewage treatment system of the present invention includes a cylinder body 1, a water inlet pipe 2 is provided on the axial top end surface of the cylinder body 1, and a drain pipe 3 is provided on the axial bottom end side wall of the cylinder body 1. ; The cylinder body 1 is provided with a settling plate 4 between the water inlet pipe 2 and the drain pipe 3, and the settling plate 4 is provided with some baffles 5, and the plate surface of the baffle plate 5 and the plate surface of the settling plate 4 Vertically, the plurality of baffles 5 are evenly distributed along the direction from one end close to the water inlet pipe 2 to one end away from the water inlet pipe 2, and the end of the settling plate 4 away from the water inlet pipe 2 is provided with a through hole 6, and the baffle plate 5 The direction of the plate surface is perpendicular to the flow direction of the sewage on the settling plate 4; a subm...

Embodiment 2

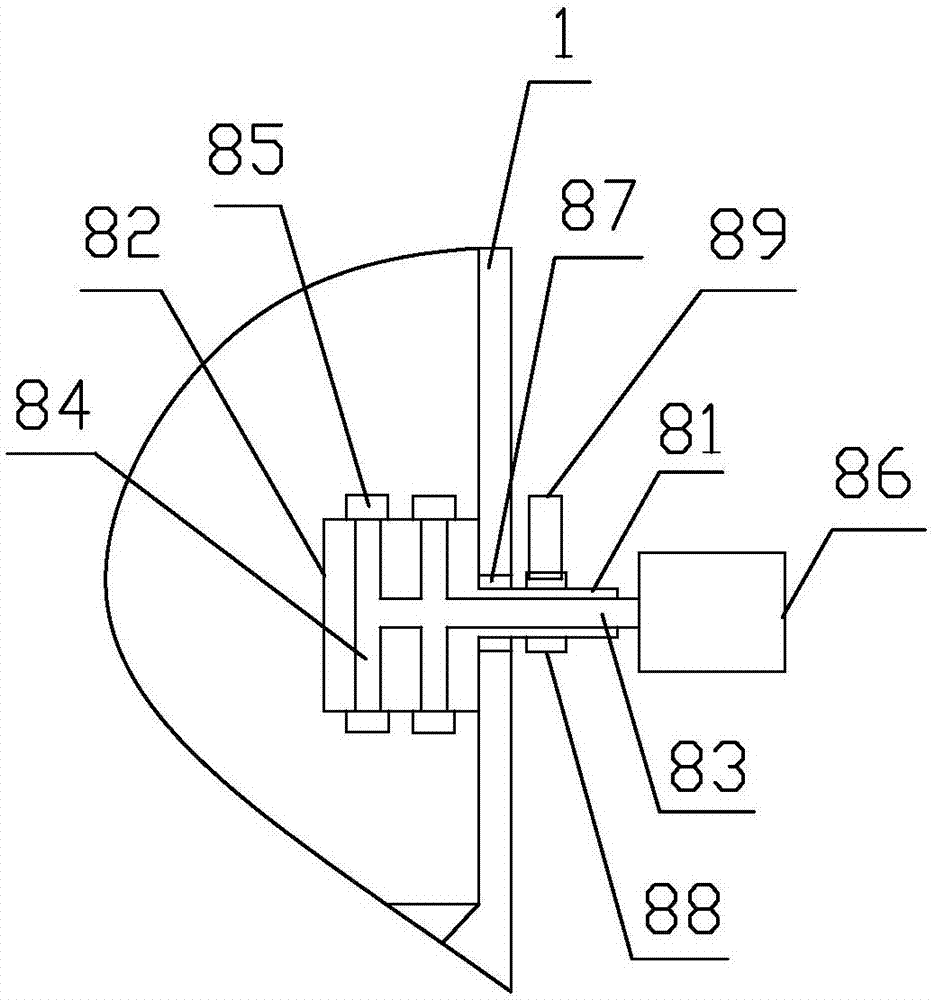

[0033]Further improvement on the basis of Example 1, the aerator 8 includes a sleeve 81, a housing 82, an intake manifold 83, an intake branch pipe 84 and a nozzle 85, and the sleeve 81 runs through the cylinder 1 and installed on the inner wall of the cylinder 1; the end of the casing 81 protruding into the cylinder 1 is provided with a housing 82, and the housing 82 is provided with a number of nozzles 85; the air intake manifold 83 Stretch into the sleeve pipe 81 to the housing 82, and be connected with the input end of the air compressor 86 at the input end of the air intake manifold 83, the output end of the intake manifold 83 located in the housing 82 is connected with some intake branch pipes 84 The input end is connected, and the output end of the intake branch pipe 84 is connected with the nozzle 85 . The sleeve 81 is rotatably connected to the inner wall of the cylinder 1 through a bearing 87; the sleeve 81 is located on the side wall of the pipe section outside the ...

Embodiment 3

[0035] As a further improvement on the basis of Embodiment 2, along the direction from one end close to the water inlet pipe 2 to one end away from the water inlet pipe 2, the heights of the several baffles 5 gradually decrease. The inner wall of the cylinder 1 is provided with a first mounting plate 11 and a second mounting plate 12 along the circumferential ring, the first mounting plate 11 and the second mounting plate 12 have an L-shaped cross-section along the axial direction of the cylinder 1, and the The settling plate 4 is pressed and fixed between the first mounting plate 11 and the second mounting plate 12 , and both the first mounting plate 11 and the second mounting plate 12 are detachably mounted on the inner wall of the barrel 1 by bolts. The first mounting plate 11 and the second mounting plate 12 are provided with sealing grooves 13 along the circumferential ring on the surface of the contacting plate of the settling plate 4, and the lower plate surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com