High-performance hinge

A high-performance, hinged technology, applied in lamination, hinged panels, door/window accessories, etc., can solve the problems of lack of wear resistance and corrosion resistance, low hardness of magnesium alloy, insufficient toughness, etc., and achieve tensile strength High, good toughness, the effect of reducing anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

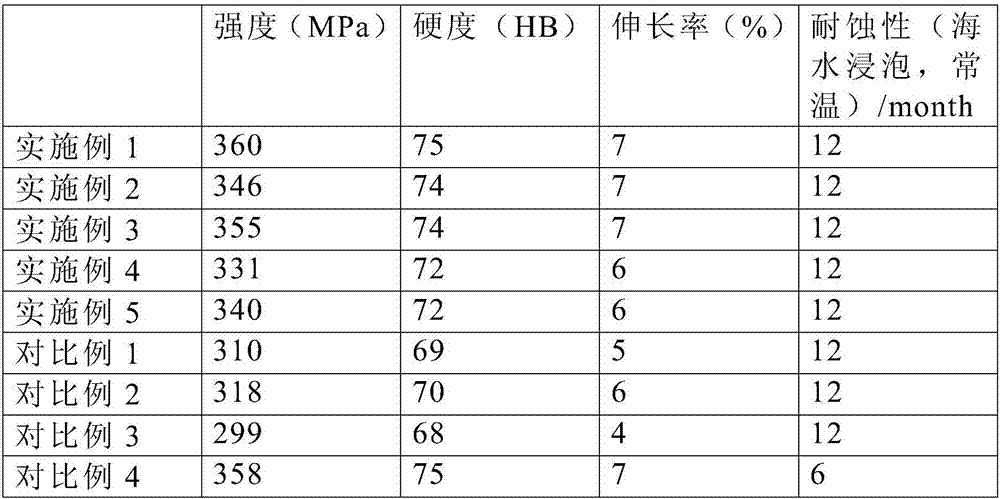

Examples

Embodiment 1

[0035] Ingredients: Weigh raw materials according to the composition and mass percentage of the above hinge, including Si: 0.2%, Zn: 0.2%, Zr: 0.06%, Ca: 0.3%, Li: 0.03%, RE: 0.05%, and the balance is Mg and impurities, wherein RE is cerium, and the impurities include H<0.002%, Fe<0.001%, N<0.001%, O<0.002%. Magnesium is directly smelted into magnesium liquid.

[0036] Pre-removal of impurities: heat up the magnesium liquid, blow inert gas from the bottom of the liquid, wrap it with tungsten after standing still, and then soak it in liquid nitrogen. After the magnesium liquid solidifies, remove impurities to obtain magnesium blocks.

[0037] Melting: Mix and melt materials other than RE with magnesium blocks to form alloy liquid, lower the temperature until the alloy liquid is semi-solid, then melt RE alone and evenly add it to the alloy liquid, and obtain magnesium alloy plates after cooling.

[0038] Heat treatment: first normalize the magnesium alloy plate at a temperature...

Embodiment 2

[0041] Ingredients: Weigh raw materials according to the composition and mass percentage of the above hinge, including Si: 0.1%, Zn: 0.1%, Zr: 0.05%, Ca: 0.2%, Li: 0.02%, RE: 0.04%, and the balance is Mg and impurities, wherein RE is yttrium, and the impurities include H<0.002%, Fe<0.001%, N<0.001%, O<0.002%. Magnesium is directly smelted into magnesium liquid.

[0042] Pre-removal of impurities: heat up the magnesium liquid, blow inert gas from the bottom of the liquid, wrap it with tungsten after standing still, and then soak it in liquid nitrogen. After the magnesium liquid solidifies, remove impurities to obtain magnesium blocks.

[0043]Melting: Mix and melt materials other than RE with magnesium blocks to form alloy liquid, lower the temperature until the alloy liquid is semi-solid, then melt RE alone and evenly add it to the alloy liquid, and obtain magnesium alloy plates after cooling.

[0044] Heat treatment: first normalize the magnesium alloy plate at a temperature...

Embodiment 3

[0047] Ingredients: Weigh raw materials according to the composition and mass percentage of the above hinge, including Si: 0.3%, Zn: 0.3%, Zr: 0.07%, Ca: 0.4%, Li: 0.04%, RE: 0.06%, and the balance is Mg and impurities, wherein RE is cerium, and the impurities include H<0.002%, Fe<0.001%, N<0.001%, O<0.002%. Magnesium is directly smelted into magnesium liquid.

[0048] Pre-removal of impurities: heat up the magnesium liquid, blow inert gas from the bottom of the liquid, wrap it with tungsten after standing still, and then soak it in liquid nitrogen. After the magnesium liquid solidifies, remove impurities to obtain magnesium blocks.

[0049] Melting: Mix and melt materials other than RE with magnesium blocks to form alloy liquid, lower the temperature until the alloy liquid is semi-solid, then melt RE alone and evenly add it to the alloy liquid, and obtain magnesium alloy plates after cooling.

[0050] Heat treatment: first normalize the magnesium alloy plate at a temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com