A device and method for detecting the inner wall of an engine cylinder based on digital holographic interference

An engine cylinder, digital holography technology, applied in measurement devices, optical devices, instruments, etc., can solve problems such as inapplicability to three-dimensional surface detection, narrow space, and inability to put laser interference systems in it, achieving good real-time performance and universality The effect of good performance and large measuring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

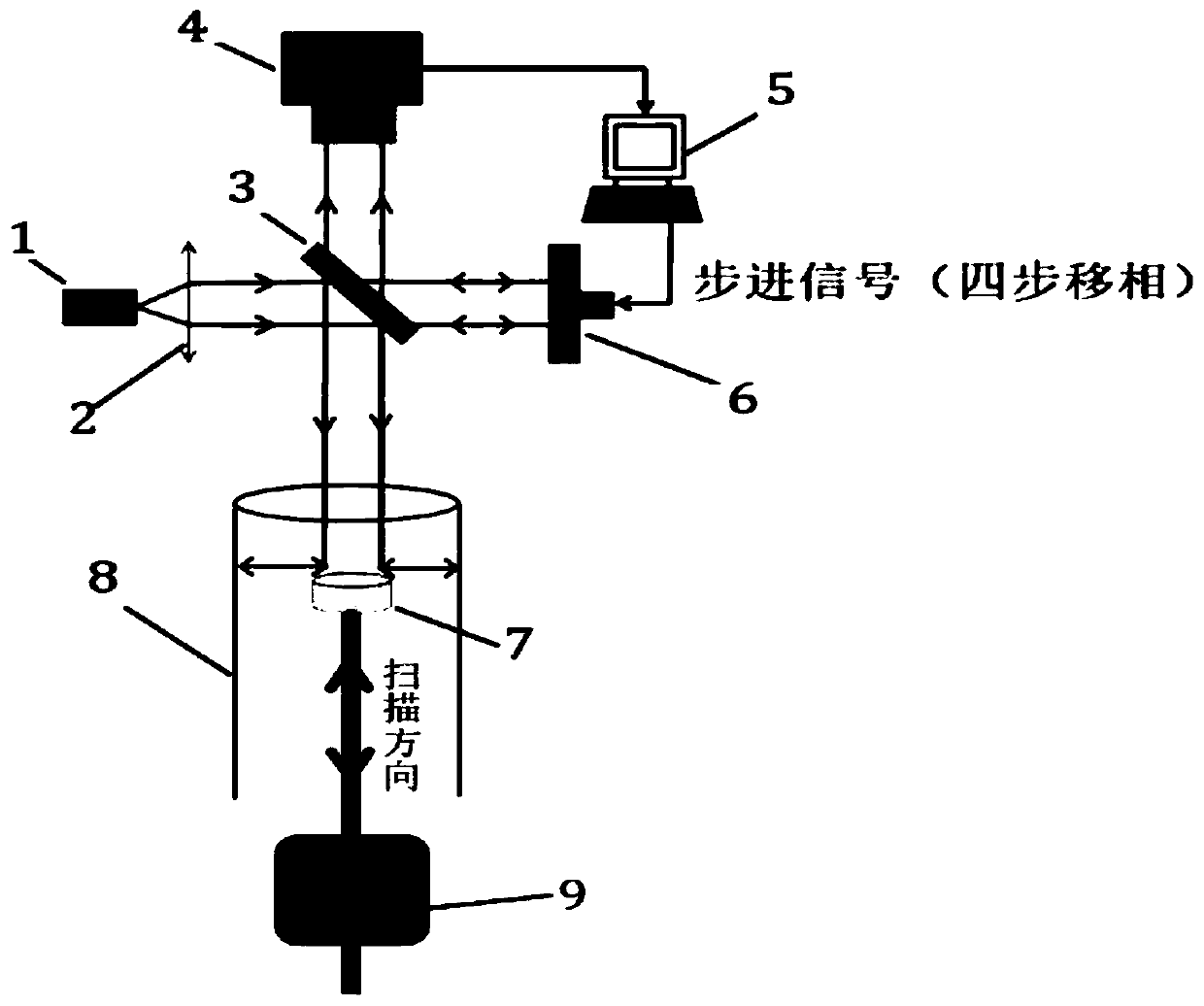

[0052] The present invention proposes and designs a method and device for detecting the inner wall of an engine cylinder based on digital holographic interference. Generally, the device is also suitable for detecting the inner wall of any other deep holes such as gun barrels and other military products that require high-precision three-dimensional inner wall detection. The application embodiment of the present invention in the technology of spraying the inner wall of cylinder processing will be described in detail below in conjunction with the accompanying drawings.

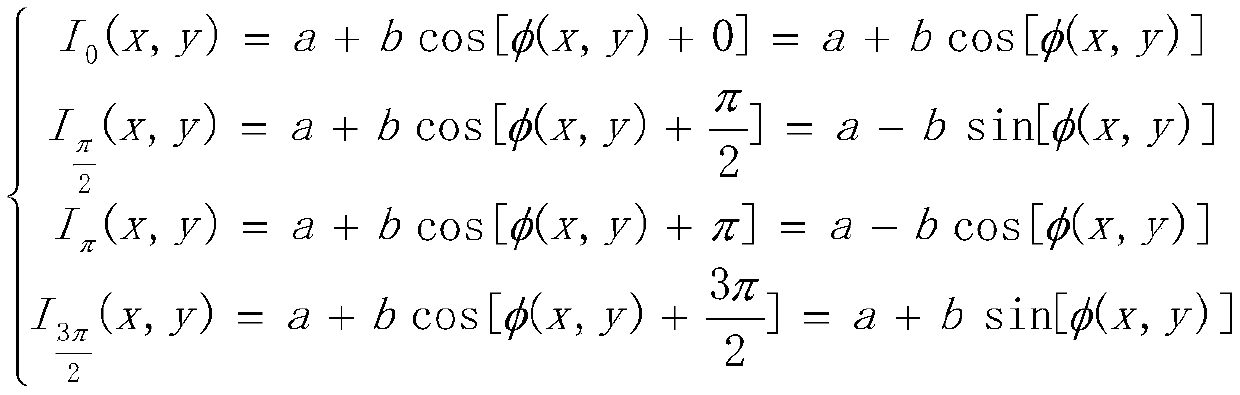

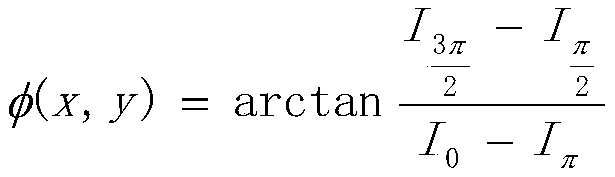

[0053] Install the laser 1 in a constant temperature and humidity vibration isolation box, so that the frequency stability is better than 10 -7 , if the experiment shows that passive frequency stabilization measures cannot make the laser reach 10 in the environment of the measurement site -7 If the frequency stability is low, use a laser integrated with active frequency stabilization technology; the laser is irra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com