Expanded bead preparation device and preparation method thereof

A preparation device and technology of expanding beads, which is applied in the field of expanding beads preparation device and its preparation, can solve the problems of fast equipment replacement frequency, high material requirements, high noise and difficult control, etc., to reduce noise pollution and reduce the degree of danger , the effect of reducing the harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

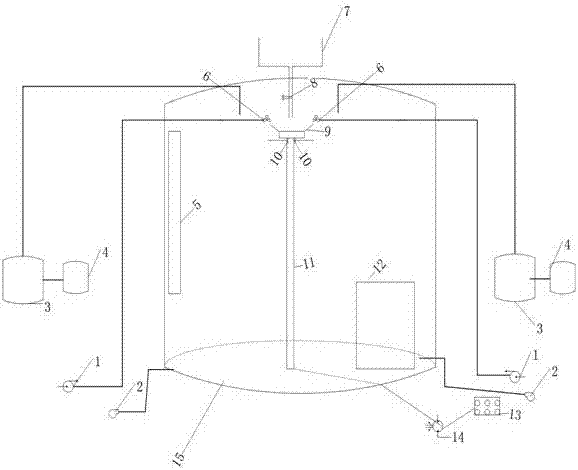

[0040] Embodiment 1: see figure 1 , an expanded bead preparation device, comprising a molten blast furnace slag drainage structure, a granulation structure, a cooling structure, a heat recovery structure and an auxiliary structure;

[0041] Molten blast furnace slag drainage structure: including graphite crucible 7 and pin 8;

[0042] The bottom of the graphite crucible 7 has a drain tube, and the pin 8 is arranged on the drain tube.

[0043] Granulation structure: including granulation furnace 15, motor 14, rotating shaft 11, turntable 9 and frequency converter 13;

[0044] The upper position of the side wall of the granulation furnace 15 is provided with an observation port 5, and the lower position of the side wall of the granulation furnace 15 is provided with a manhole 12; during specific implementation, the observation port 5 is made of quartz glass.

[0045] The rotating shaft 11 is arranged in the granulation furnace 15;

[0046] The turntable 9 is wide at the top a...

Embodiment 2

[0055] Embodiment 2: a kind of preparation method of expanded beads, adopts the expanded beads preparation device described in embodiment 1, and preparation steps are as follows:

[0056] S1: Turn on and adjust the frequency converter 13 and the motor 14, the rotation of the rotating shaft 11 drives the turntable 9 on the top of the rotating shaft to rotate; the frequency converter is also placed outside the granulation furnace to facilitate adjustment, opening and closing of the motor.

[0057] S2: Turn on the water pump 1 and the water valve nozzle 6, and observe whether the water scattering angle and water volume sprayed by the water valve nozzle 6 meet the requirements through the observation window; if it is satisfied, continue to the next step; if not, stop the motor 14 and the water pump 1 Come, debug the water valve nozzle 6 until the requirements are met, then proceed to the next step.

[0058] S3: Open the pin 8, and the molten blast furnace slag enters from the grap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com