Continuous polypropylene wax production process

A polypropylene wax and production process technology, applied in the field of polypropylene wax, can solve the problems of high viscosity of polypropylene wax, affecting product quality, deterioration of heat transfer state, etc., shortening the reaction period, avoiding wall sticking and carbonization, and preventing carbides The effect of falling into the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

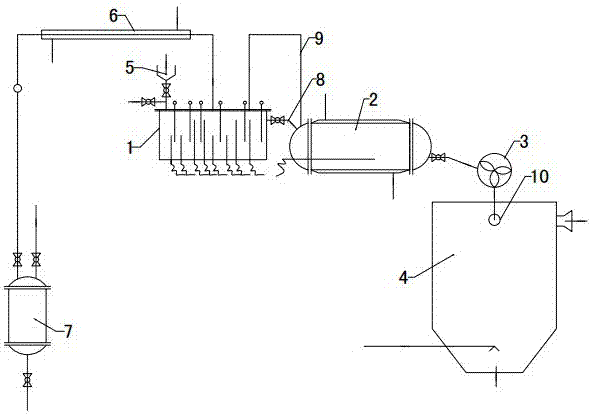

[0027] 1) Put 300kg of polypropylene wax raw meal into the cracking kettle 1 every 30 minutes; the polypropylene wax raw meal enters the cracking kettle 1 from the polypropylene feed port 5, and the cracking kettle 1 starts to heat up intermittently and rises to 375°C;

[0028] 2) The low fraction is discharged through the extraction pipe on the cracking kettle 1, condensed by the condenser 6, and extracted to the low fraction storage tank 7;

[0029] 3) The molten polypropylene wax is extracted from the polypropylene outlet to the buffer tank 2 for temporary storage; the buffer tank 2 controls the temperature of the stored polypropylene wax at 375°C through steam cooling or heating rod heating; the buffer tank 2 is equipped with a thermocouple And thermostat, automatically control the steam to cool down or the heating rod to heat up.

[0030] 4) The molten polypropylene wax in the buffer tank 2 is continuously sprayed and granulated by the atomizer 3, and then cooled and drie...

Embodiment 2

[0033] 1) Put 270kg of polypropylene wax raw meal into the cracking kettle 1 every 28 minutes; the polypropylene wax raw meal enters the cracking kettle 1 from the polypropylene feed port 5, and the cracking kettle 1 starts to heat up intermittently and rises to 378°C;

[0034] 2) The low fraction is discharged through the extraction pipe on the cracking kettle 1, condensed by the condenser 6, and extracted to the low fraction storage tank 7;

[0035] 3) The melted polypropylene wax is extracted from the polypropylene outlet to the buffer tank 2 for temporary storage; the buffer tank 2 controls the temperature of the stored polypropylene wax at 378°C through steam cooling or heating rod heating; the buffer tank 2 is equipped with a thermocouple And thermostat, automatically control the steam to cool down or the heating rod to heat up.

[0036] 4) The molten polypropylene wax in the buffer tank 2 is continuously sprayed and granulated by the atomizer 3, and then cooled and drie...

Embodiment 3

[0039] 1) Put 320kg of polypropylene wax raw meal into the cracking kettle 1 every 32 minutes; the polypropylene wax raw meal enters the cracking kettle 1 from the polypropylene feed port 5, and the cracking kettle 1 starts to heat up intermittently and rises to 372°C;

[0040] 2) The low fraction is discharged through the extraction pipe on the cracking kettle 1, condensed by the condenser 6, and extracted to the low fraction storage tank 7;

[0041] 3) The molten polypropylene wax is extracted from the polypropylene outlet to the buffer tank 2 for temporary storage; the buffer tank 2 controls the temperature of the stored polypropylene wax at 372°C through steam cooling or heating rod heating; the buffer tank 2 is equipped with a thermocouple And thermostat, automatically control the steam to cool down or the heating rod to heat up.

[0042]4) The molten polypropylene wax in the buffer tank 2 is continuously sprayed and granulated by the atomizer 3, and then cooled and dried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com