Novel glass fiber enhanced PBT (Polybutylene Terephthalate) composition

A technology of composition and glass fiber, which is applied in the field of polymer modification, can solve problems such as limiting the scope of application, and achieve the effect of enhancing interface bonding force and improving impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

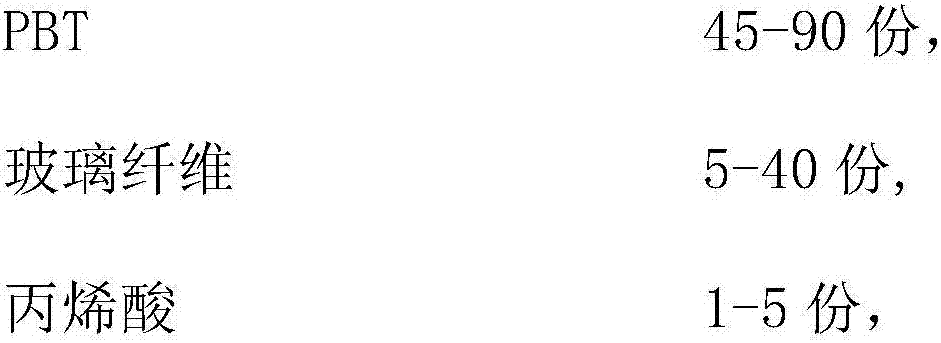

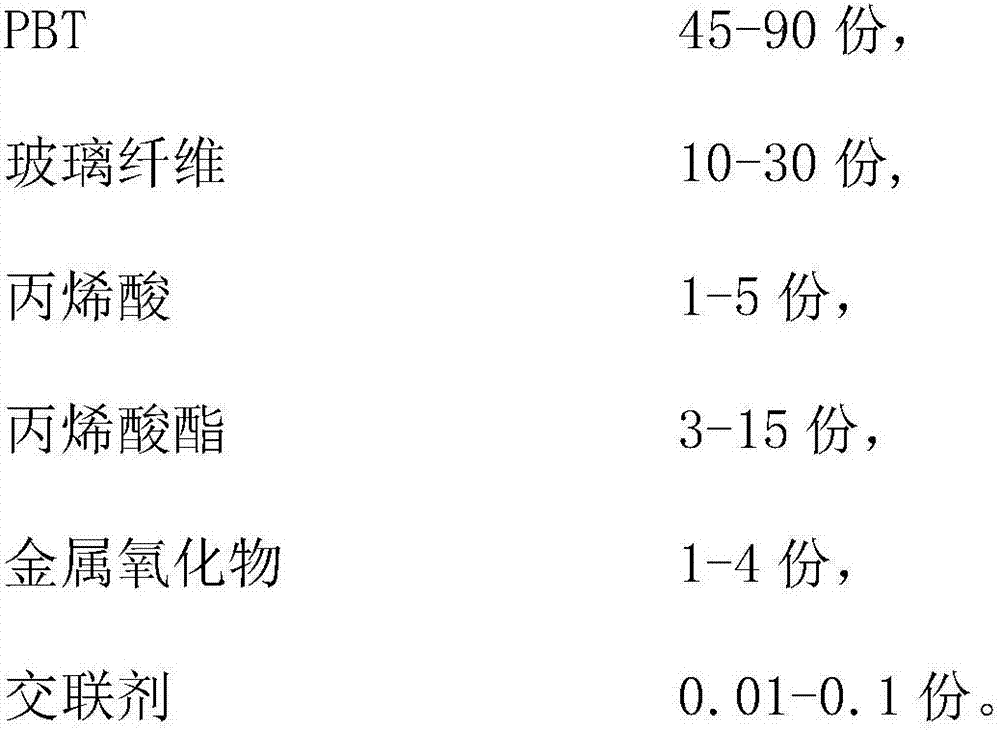

Method used

Image

Examples

Embodiment 1

[0026] A novel glass fiber reinforced PBT composition, the composition is made of raw materials comprising the following parts by weight: 85 parts of PBT, 10 parts of glass fiber, 3 parts of acrylic acid, 4 parts of butyl acrylate, 1.5 parts of zinc oxide, 0.01 part of DCP , 0.2 parts of antioxidant, 0.5 parts of lubricant.

[0027] The preparation method of the novel glass fiber-reinforced PBT composition comprises the following steps: first put the raw materials into a high-speed mixer and mix them for 3 minutes, then put them into a twin-screw extruder, and control the temperature at 200°C- 300°C, extrude and granulate.

Embodiment 2

[0029] A novel glass fiber reinforced PBT composition, the composition is made of raw materials comprising the following parts by weight: 70 parts of PBT, 20 parts of glass fiber, 4 parts of acrylic acid, 5 parts of butyl acrylate, 3 parts of zinc oxide, and 0.02 part of DCP , 0.2 parts of antioxidant, 0.5 parts of lubricant.

[0030] The preparation method of the novel glass fiber-reinforced PBT composition comprises the following steps: first put the raw materials into a high-speed mixer and mix them for 3 minutes, then put them into a twin-screw extruder, and control the temperature at 200°C- 300°C, extrude and granulate.

Embodiment 3

[0032] A novel glass fiber reinforced PBT composition, the composition is made of raw materials comprising the following parts by weight: 55 parts of PBT, 30 parts of glass fiber, 6 parts of acrylic acid, 8 parts of butyl acrylate, 4 parts of zinc oxide, and 0.03 part of DCP , 0.2 parts of antioxidant, 0.5 parts of lubricant.

[0033] The preparation method of the novel glass fiber-reinforced PBT composition comprises the following steps: first put the raw materials into a high-speed mixer and mix them for 3 minutes, then put them into a twin-screw extruder, and control the temperature at 200°C- 300°C, extrude and granulate.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap