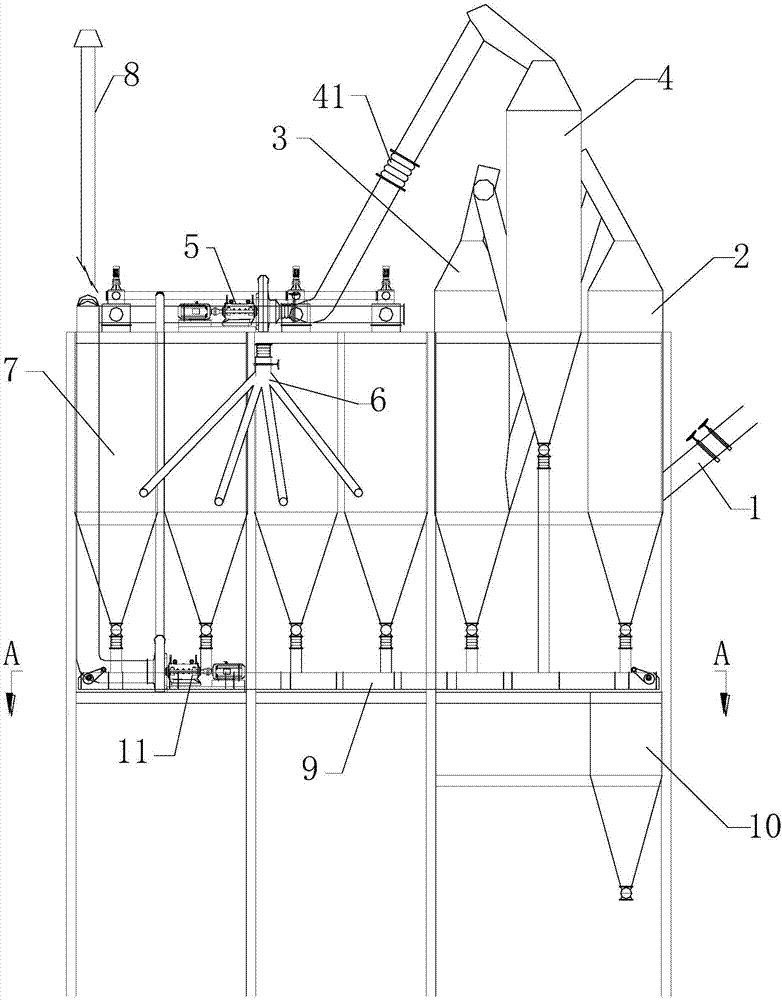

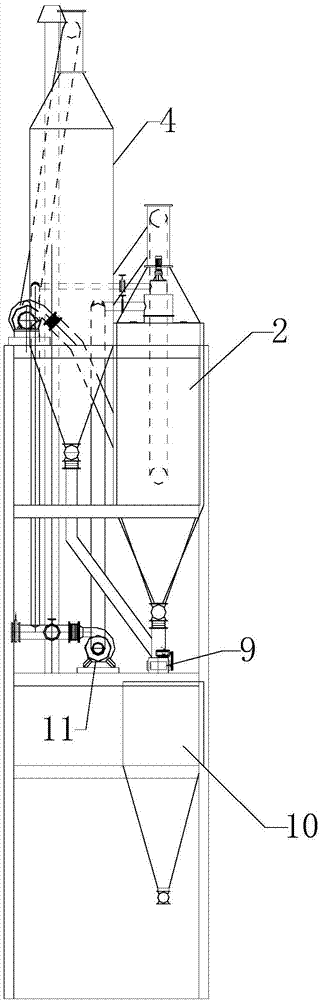

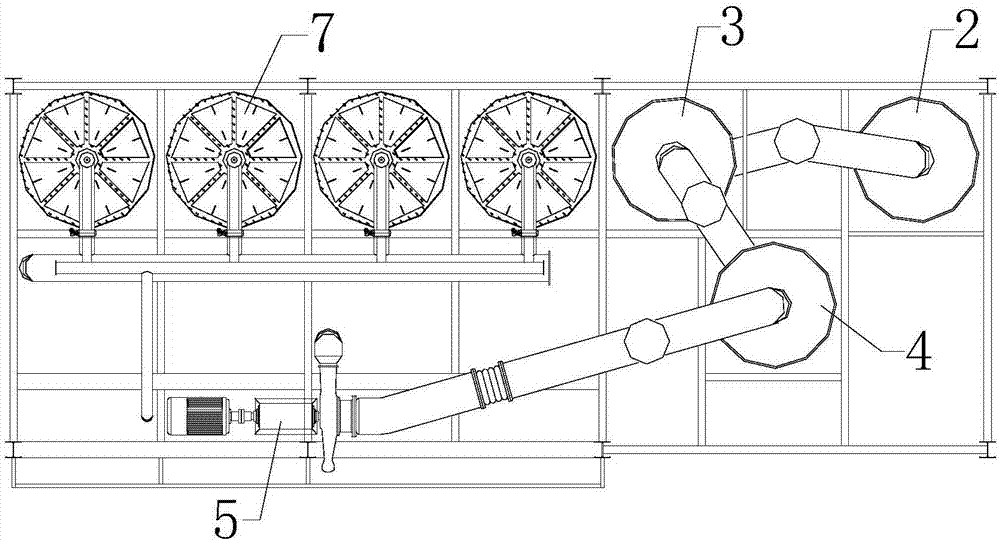

Submerged arc furnace gas recycling method and equipment

A submerged arc furnace and gas technology, which is applied in separation methods, chemical instruments and methods, gas dust removal, etc., can solve the problems of excessive exhaust gas, environmental pollution, and inability to discharge directly, and achieve long equipment service life, simple and easy-to-operate methods, Good equipment stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0024] It should be noted that, unless otherwise specified, the technical terms or scientific terms used in this application shall have the usual meanings understood by those skilled in the art to which the present invention belongs.

[0025] In the description of the present application, it should be understood that the terms "first", "second", etc. are used for descriptive purposes only, and cannot be interpreted as indicating or implying relative importance or implicitly indicating the number of indicated technical features .

[0026] In this application, unless otherwise clearly specified and limited, the term...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap