Grinding process for natural-color bamboo pulp

A technology of natural-color bamboo pulp and pulp refining, applied in the field of papermaking, can solve problems such as easy breakage, difficult separation of long fiber components, and the influence of bamboo pulp performance on paper-making performance, etc., to achieve improved water filtration capacity, The effect of excellent paper quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

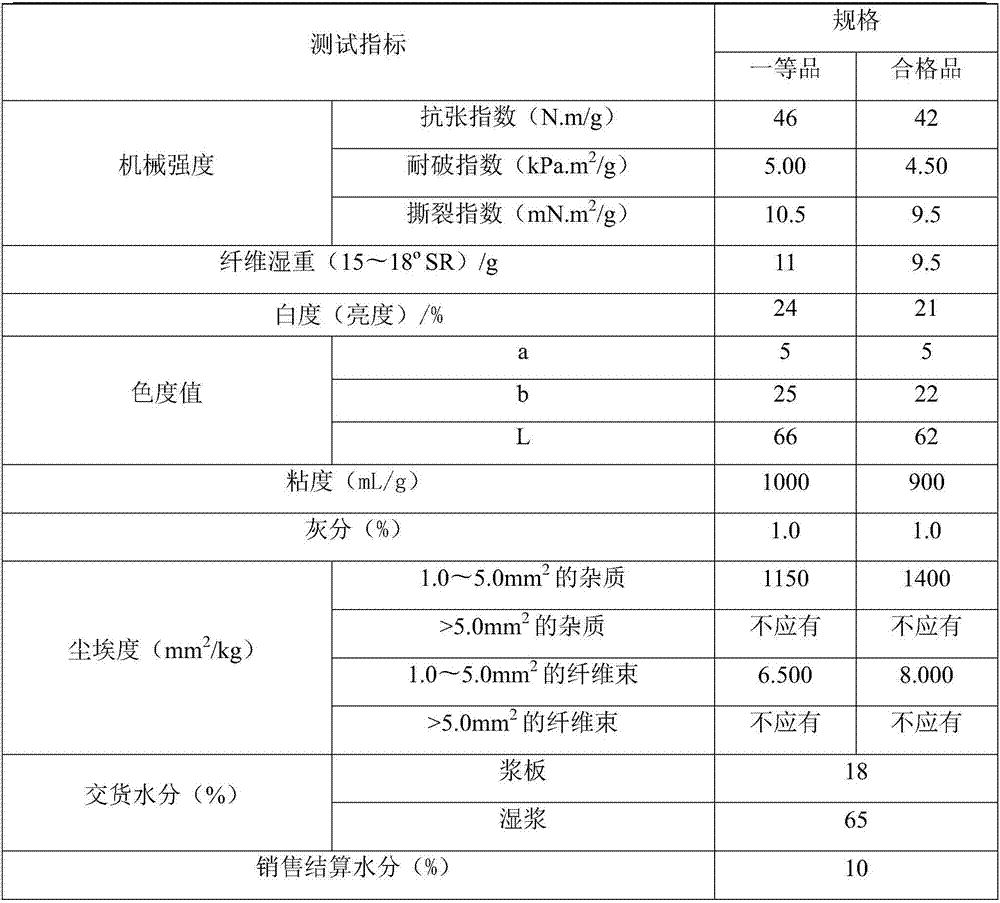

Embodiment 1

[0032] The preparation of a, 30 ° natural color bamboo pulp:

[0033] Softening: Put the moso bamboo slices prepared by wet method and 5% sodium hydroxide cooking liquid into the horizontal tube presoaker, put steam into the presoaker for heating, heat the steam to 70°C, and keep it warm for 60min; , the weight ratio of bamboo and cooking liquid is 1:3;

[0034] Kneading: Extrude and knead the softened bamboo fiber through a single-screw dipping and kneading machine. The single-screw dipping and kneading machine includes a prepreg, an extrusion kneading zone, a material and liquid mixing zone, and a cooking tube. The time for extruding and rubbing is 1min, and the compression ratio is 1:2; the filtrate after extruding and rubbing is recycled to cooking after removing impurities through a filter;

[0035] Mixing: Pour 5% sodium hydroxide cooking liquid preheated to 70°C into the material and liquid mixing area of the dipping and kneading machine, mix for 30 seconds by spiral...

Embodiment 2

[0049] The preparation of a, 30 ° natural color bamboo pulp:

[0050] Softening: Put the moso bamboo slices prepared by wet method and 5% sodium hydroxide cooking liquid into the horizontal tube presoaker, put steam into the presoaker for heating, heat the steam to 70°C, and keep it warm for 60min; , the weight ratio of bamboo and cooking liquid is 1:3;

[0051] Kneading: Extrude and knead the softened bamboo fiber through a single-screw dipping and kneading machine. The single-screw dipping and kneading machine includes a prepreg, an extrusion kneading zone, a material and liquid mixing zone, and a cooking tube. The time for extruding and rubbing is 1min, and the compression ratio is 1:2; the filtrate after extruding and rubbing is recycled to cooking after removing impurities through a filter;

[0052] Mixing: Pour 5% sodium hydroxide cooking liquid preheated to 70°C into the material and liquid mixing area of the dipping and kneading machine, mix for 30 seconds by spiral...

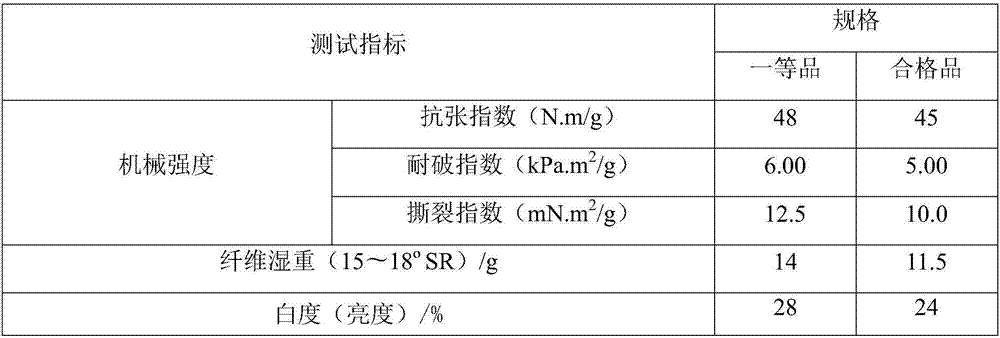

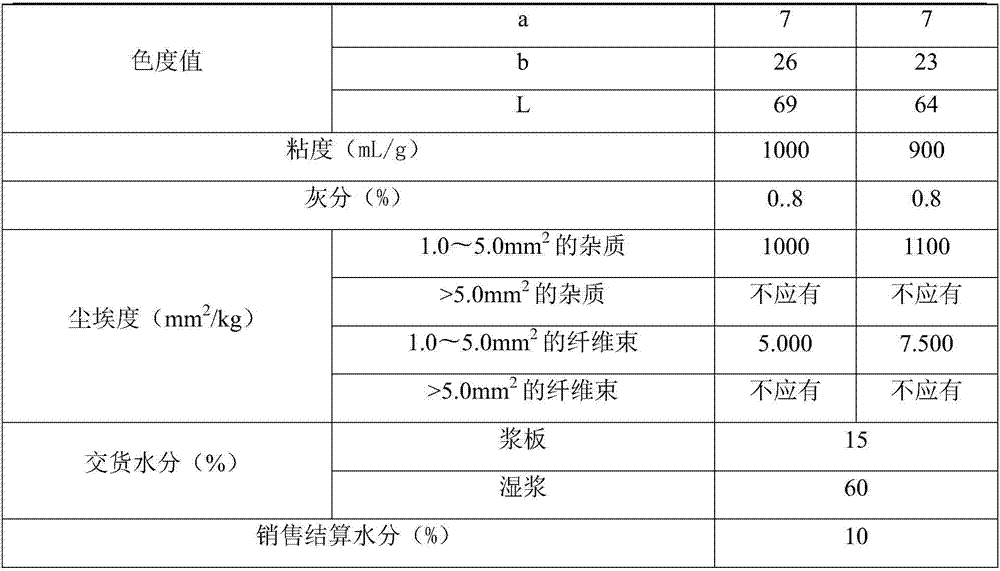

Embodiment 3

[0067] The preparation of a, 30 ° natural color bamboo pulp:

[0068] Softening: Put the moso bamboo slices prepared by wet method and 5% sodium hydroxide cooking liquid into the horizontal tube presoaker, put steam into the presoaker for heating, heat the steam to 70°C, and keep it warm for 60min; , the weight ratio of bamboo and cooking liquid is 1:3;

[0069] Kneading: Extrude and knead the softened bamboo fiber through a single-screw dipping and kneading machine. The single-screw dipping and kneading machine includes a prepreg, an extrusion kneading zone, a material and liquid mixing zone, and a cooking tube. The time for extruding and kneading is 1 min, and the compression ratio is 1:2; the filtrate after squeezing and kneading is passed through a filter to remove impurities and then recycled to cooking;

[0070] Mixing: Pour 5% sodium hydroxide cooking liquid preheated to 70°C into the material and liquid mixing area of the dipping and kneading machine, mix for 30 sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com