Active vibration reduction boring rod based on electromagnetic damper

An electromagnetic damper, active technology, applied in the direction of boring bars, shock absorbers, tools for lathes, etc., can solve the problems of difficult, complex, and prone to failure structures in manufacturing, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

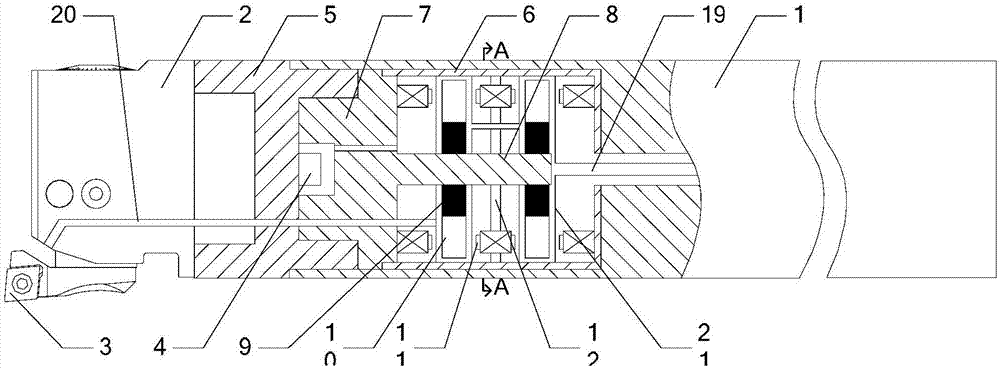

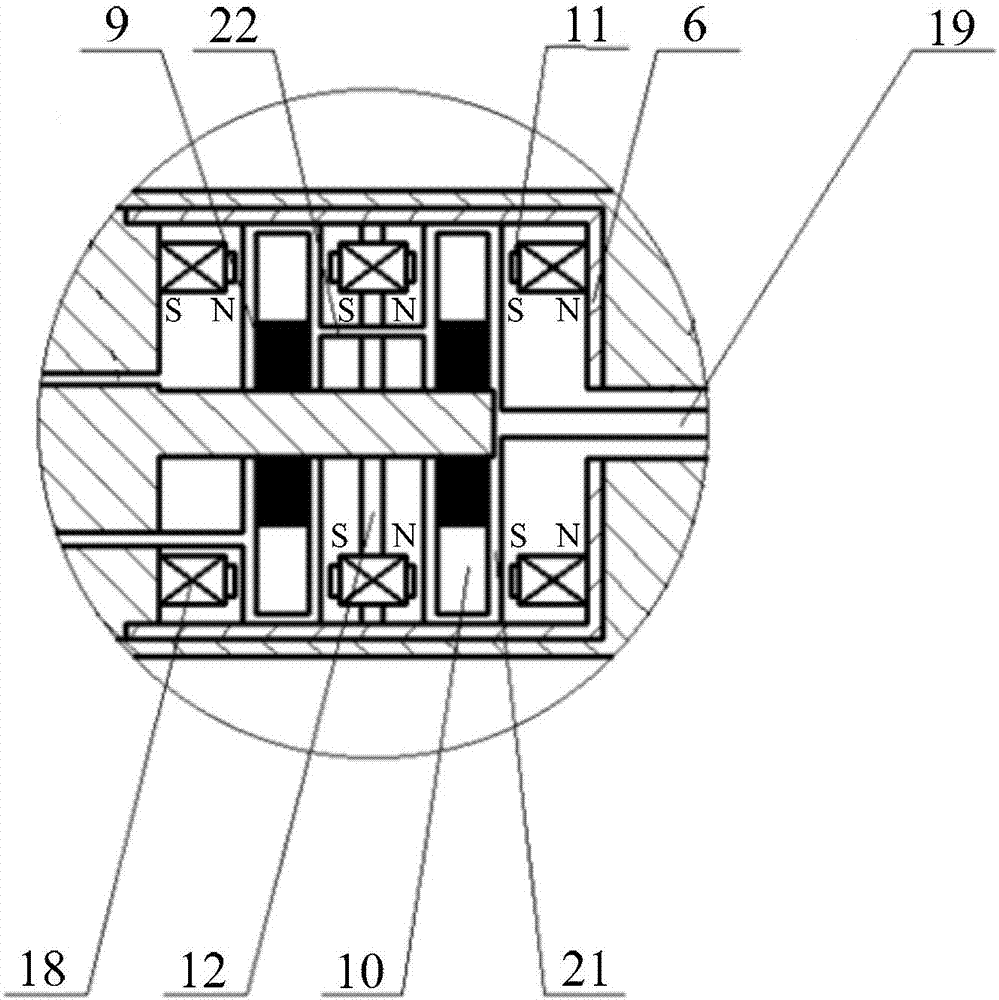

[0057] Embodiment: combine below Figure 1 to Figure 7 This embodiment will be described in detail.

[0058] The active damping boring bar based on the electromagnetic damper described in this embodiment includes a rod body 1, and a cutter head 2 is arranged at the front end of the rod body 1, and the cutter head 2 is used for clamping the blade 3;

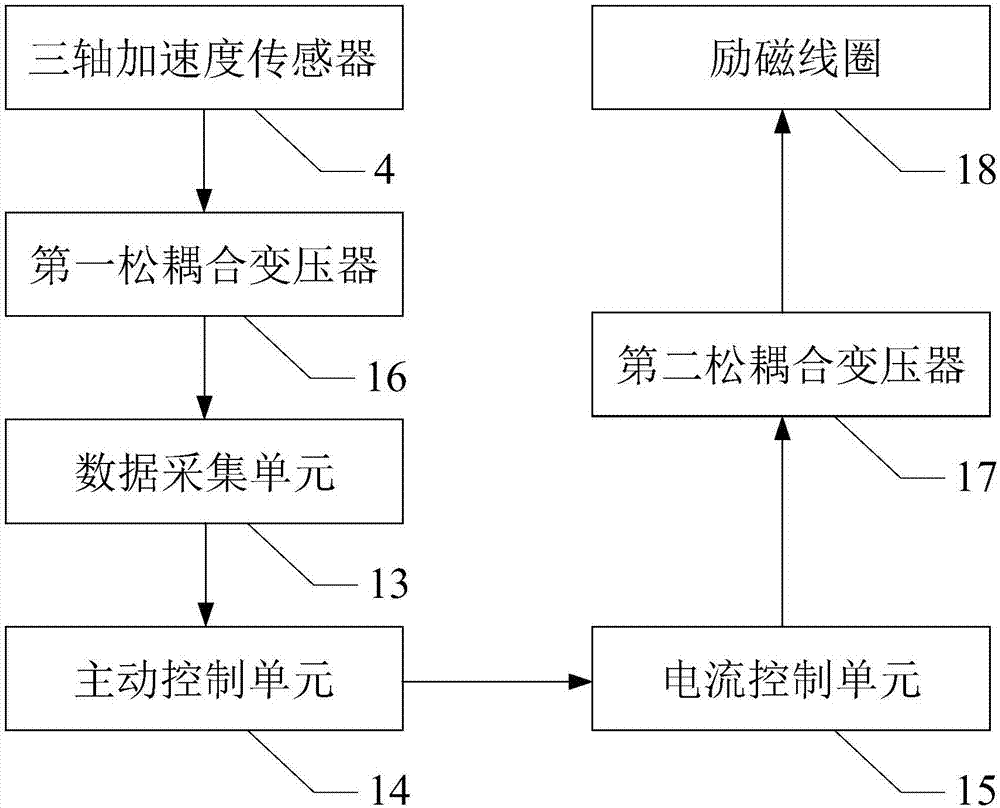

[0059] The damping boring bar also includes an electromagnetic damper, a triaxial acceleration sensor 4 and a control system;

[0060] The electromagnetic damper is arranged inside the rod body 1;

[0061] When the damping boring bar is used for boring processing, the triaxial acceleration sensor 4 is used to measure the acceleration data of the bar body 1 and send it to the control system;

[0062] The control system is used to adjust the damping coefficient of the electromagnetic damper until the acceleration data it receives reaches the minimum.

[0063] The active damping boring bar based on the electromagnetic damper descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com