Permeation coefficient tester for irregular sample under different hydraulic pressure conditions and test method

A water permeability coefficient and irregular technology, applied in the direction of measuring devices, scientific instruments, permeability/surface area analysis, etc., can solve the problems of cumbersome operation process, damage of test equipment, difficult cleaning, etc., to improve test efficiency, high degree of automation, The effect of improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

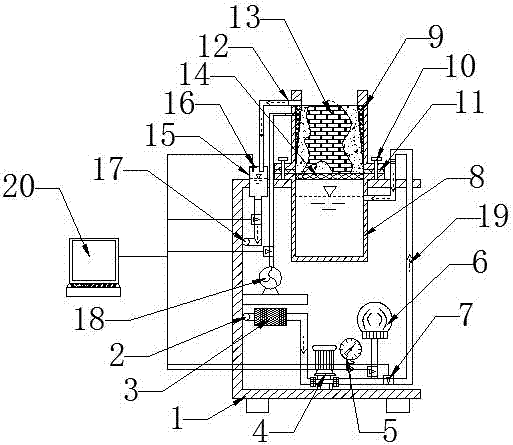

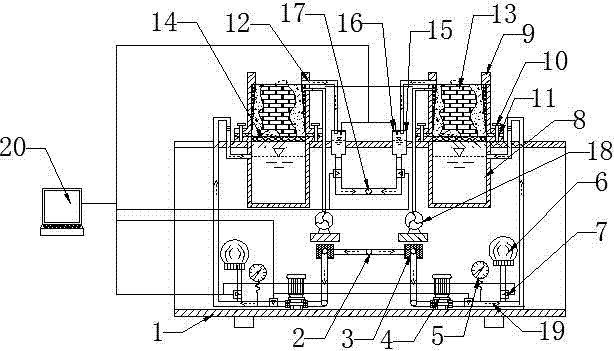

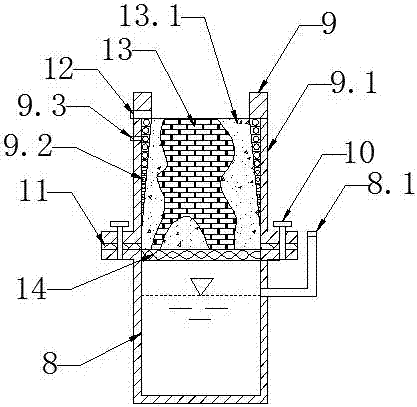

[0027] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] see Figure 1-Figure 6 , a water permeability coefficient tester for irregular samples under different water pressure conditions of the present invention, comprising a test bench 1, a sample fixing device 9 and an electronic control system, the lower part of the test bench 1 is provided with a water inlet pipe 2, and the water inlet pipe 2 is connected with a filter device 3. The filter device 3 is connected to the water inlet of the electric pump 4 through a pipeline, and the water outlet of the electric pump 4 is connected to the water inlet 8.1 of the water storage container through a pipeline. Between the water outlet of the electric pump 4 and the water inlet 8.1 of the water storage container An accumulator 6 is provided, a water storage container 8 is provided in the middle of the test bench 1, and a permeable steel wire mesh 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com