Device for detecting initial rotor position of PMSM (permanent-magnet synchronous motor)

A technology of permanent magnet synchronous motor and rotor initial position, which can be used in the control of electromechanical transmission, generator control, motor control, etc., and can solve the problems of dependence, low precision, and complex implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

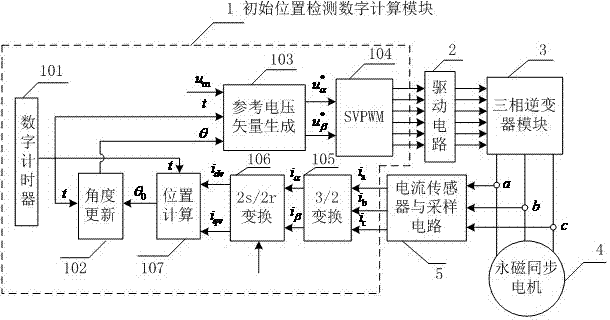

[0043] Embodiment 1: as figure 1 As shown, a rotor initial position detection device of a permanent magnet synchronous motor includes an initial position detection digital calculation module 1, a drive circuit 2, a three-phase inverter module 3, a permanent magnet synchronous motor 4, a current sensor and a sampling circuit 5, the The driving circuit 2 receives the signal of the initial position detection digital calculation module 1, generates the driving signal of the IGBT,

[0044] The three-phase inverter module 3 controls the upper and lower bridge arm IGBTs of each phase to be turned on and off according to the drive signal generated by the drive circuit 2, and the three-phase stator of the permanent magnet synchronous motor 4 is connected to the three-phase inverter The current sensor and the sampling circuit 5 collect the a, b and c three-phase stator currents (ia, ib and ic) of the permanent magnet synchronous motor 4.

[0045] Described initial position detection di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com