Iron phosphide film hydrogen evolution catalyst and preparation method thereof

A technology of iron phosphide and catalyst, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve problems such as poor stability, low performance of electrocatalytic hydrogen evolution, and high price. Achieve significant technological progress, efficient cycle stability, safe and environmentally friendly preparation of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: the preparation method of the iron phosphide thin film hydrogen evolution catalyst involved in the present embodiment comprises the following two steps:

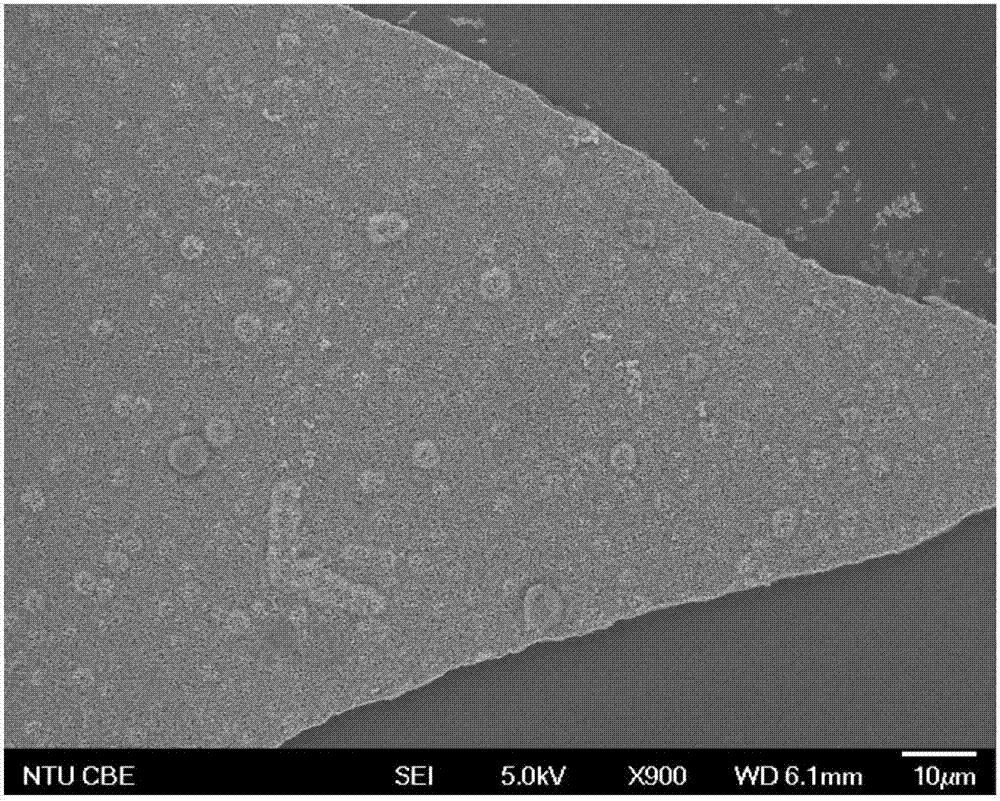

[0022] Step 1): synthesis of iron oxyhydroxide film by hot solvent method. Weigh 3.2g hydrated ferrous sulfate crystals (FeSO 4 ·7H 2 O) join in the mixed solution of 160ml glycerol and water (the volume ratio of glycerol and water is 1:3), stir evenly, then transfer in the 200mL reactor, the reactor is warmed up to 120 ℃, reacts 24h. The resulting product was washed several times with deionized water and ethanol, respectively. Dry at room temperature. A film-like iron oxyhydroxide precursor was obtained.

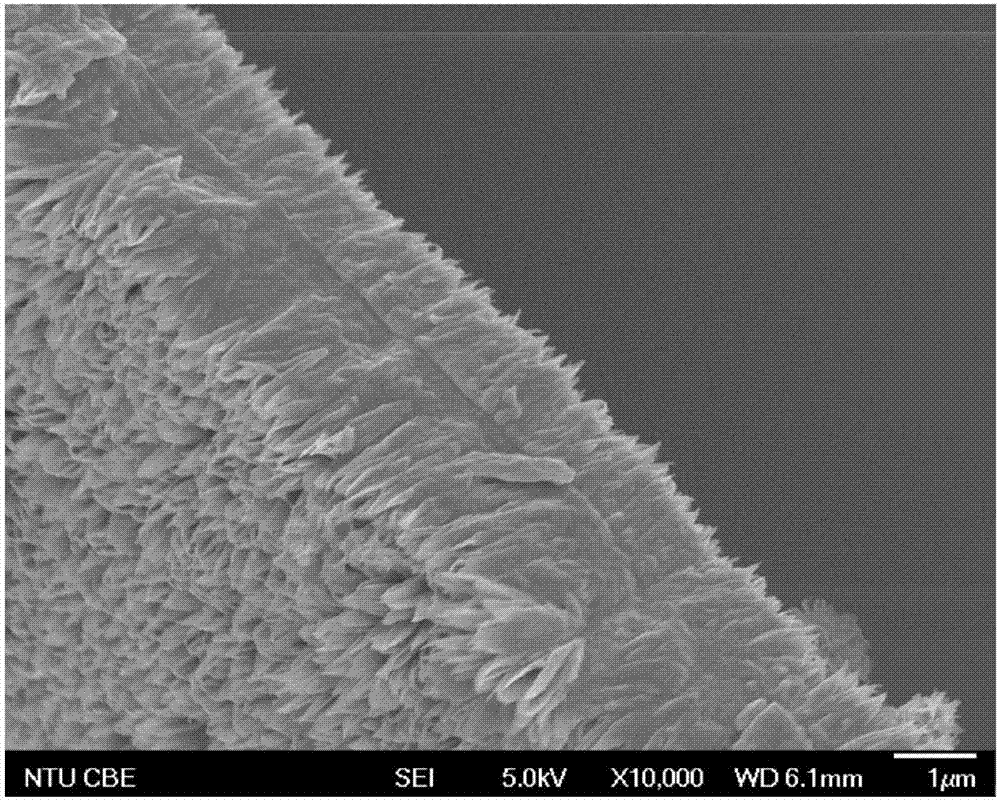

[0023] Step 2): performing temperature-controlled phosphating on the iron oxyhydroxide film to form an iron phosphide film. A certain amount of the above-mentioned iron oxyhydroxide film is placed in the downstream of the adaptation reaction tube, and a certain amount of sodium dihydrogen phospha...

Embodiment 2

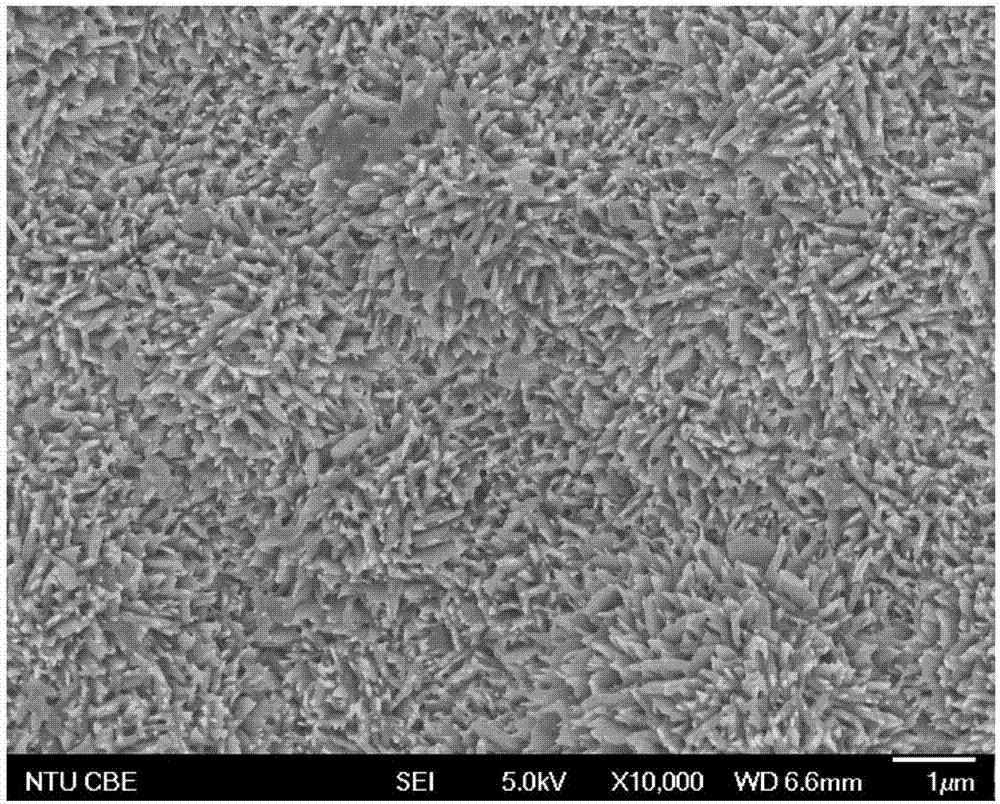

[0024] Example 2: Referring to the operation of step 2) in Example 1, the phosphating conditions were changed to 450 °C at a rate of 2 °C / min in a 20 mL / min Ar flow and maintained for 1 h, and then cooled to room temperature to obtain high crystallization Iron phosphide thin film catalyst, denoted as FeP-450℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com