Preparing method for gold-silver alloy hollow polyhedron

A technology of gold-silver alloy and polyhedron, which is applied in the field of preparation of gold-silver alloy hollow polyhedron, can solve the problems of thin wall and easy breakage of the hollow structure, and achieve the effect of being strong and broken and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a gold-silver alloy hollow polyhedron, comprising the steps of:

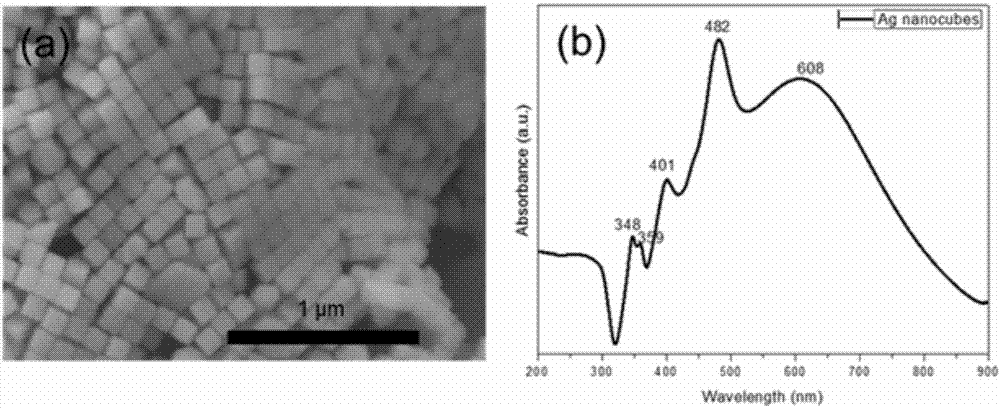

[0027] Step A: Silver nanocubes are prepared in an oil bath at 150-195° C. by polyalcohol reduction method.

[0028] Step B, dispersing the silver nanocubes into a surfactant solution, thereby obtaining surfactant-dispersed silver nanocubes.

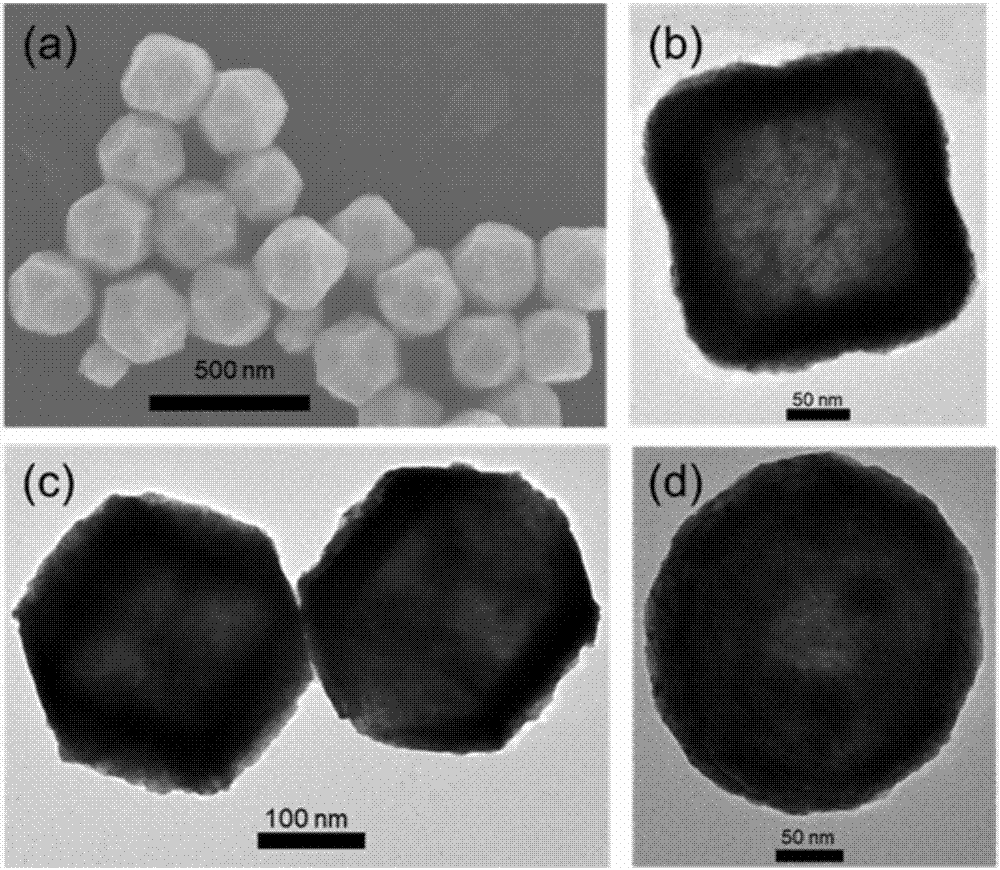

[0029] Step C, adding a reducing agent and surfactant-dispersed chloroauric acid to the surfactant-dispersed silver nanocubes sequentially, reacting for 10 minutes to 2 hours, then performing centrifugation, and then washing the solid obtained after centrifugation, so that A gold-silver alloy hollow polyhedron is obtained.

Embodiment approach

[0031] (1) In step A, the described employing polyol reduction method to prepare silver nanocubes in an oil bath at 150~195°C may include the following steps:

[0032] ① Step A1, using 1,5-pentanediol as a solvent to prepare silver nitrate solutions with a concentration of 10-50 mg / mL (preferably 20 mg / mL) and a concentration of 10-50 mg / mL (preferably 20 mg / mL) ) solution of polyvinylpyrrolidone and a concentration of 10 to 50 mg / mL (preferably 10 mg / mL) of anhydrous cupric chloride solution, and dispersing the anhydrous cupric chloride solution into the silver nitrate solution, thereby An anhydrous copper chloride solution in which silver nitrate is dispersed is obtained.

[0033] ②Step A2, take 2.5~10mL (preferably 5mL) of 1,5-pentanediol in a reaction vessel, and place it in an oil bath at 150~195°C (preferably 175°C), Stir at a rate of 300r / min (preferably 280r / min), make it evenly heated, keep warm for 10-30min (preferably 20min), then add the anhydrous chlorine dispers...

Embodiment 1

[0044] A method for preparing a gold-silver alloy hollow polyhedron, comprising the steps of:

[0045] Step a1, using 1,5-pentanediol as a solvent to configure respectively a silver nitrate solution with a concentration of 20mg / mL, a polyvinylpyrrolidone solution with a concentration of 20mg / mL and an anhydrous copper chloride solution with a concentration of 20mg / mL, and The anhydrous copper chloride solution is dispersed into the silver nitrate solution to obtain an anhydrous copper chloride solution dispersed in silver nitrate.

[0046] Step b1: Take 5mL of 1,5-pentanediol in a single-necked glass bottle, place it in an oil bath at 175°C, stir it at a speed of 280r / min, make it evenly heated, keep it warm for 20min, and then pour it into the Alternately add the silver nitrate-dispersed anhydrous cupric chloride solution and polyvinylpyrrolidone solution in step a1 to the single-necked glass bottle at a rate of 125 uL / min, and the number of additions is 18 times.

[0047] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com