Driving device for new energy motor vehicles

A technology for driving devices and motor vehicles, which is applied to the arrangement of multiple prime movers of power devices, pneumatic power devices, and general power devices, and can solve unfavorable motor vehicle weight control and space layout, ride experience and cruising range Unable to meet the problems, such as large volume of the mechanism, to achieve the effect of easy installation and arrangement, compact structure and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

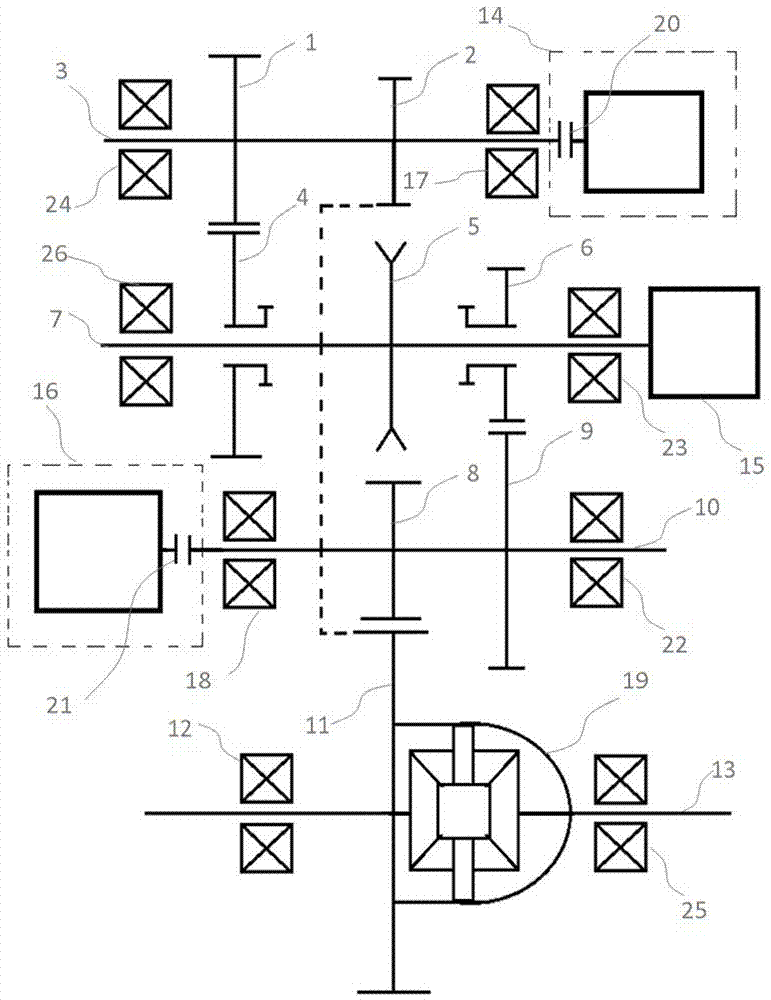

[0040] Such as figure 1 A driving device for a new energy motor vehicle shown includes a rotating mechanism arranged between the driver and the output device, wherein the transmission mechanism includes an input shaft 7 and a first transmission shaft with planets arranged on the circumference of the input shaft 7 3. The second transmission shaft 10; wherein, the driver includes a power source 15, the power source 15 is a motor or an internal combustion engine, the power source 15 is coupled to the input shaft 7, and the first input bearing 26 and the second input shaft 7 are respectively arranged at both ends of the input shaft 7. Bearing 23; wherein, the first drive gear 4 and the second drive gear 6 are empty between the first and second input bearings 26, 23 of the input shaft 7; wherein, the first and second drive gears 4, 6 of the input shaft 7 6 is provided with a synchronizing device 5 in the middle; wherein, the first transmission bearing 24 and the second transmission...

Embodiment 2

[0050] The technical solution described in embodiment two is similar to embodiment one, and its difference is:

[0051]In this embodiment, the driver further includes a first driving device 14 , the end of the first transmission shaft 3 provided with a first transmission bearing 24 is connected to the first driving device 14 through a first clutch device 20 , and the first driving device 14 is a motor.

[0052] The second transmission shaft 10 does not have a driver at both ends.

Embodiment 3

[0054] The technical solution described in embodiment three is similar to embodiment one, and its difference is:

[0055] In this embodiment, the driver further includes a second driving device 16, the end of the second transmission shaft 10 provided with the third transmission bearing 18 is connected to the second driving device 16 through the second clutch device 21, and the second driving device 16 is a motor.

[0056] There is no driver at both ends of the first transmission shaft 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com