Method for synthesizing Silicalite-1 molecular sieve with TPABr being template agent

A technology of molecular sieves and templates, applied in the direction of silica, silicon oxide, etc., can solve the problems of expensive templates, large-scale use of templates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

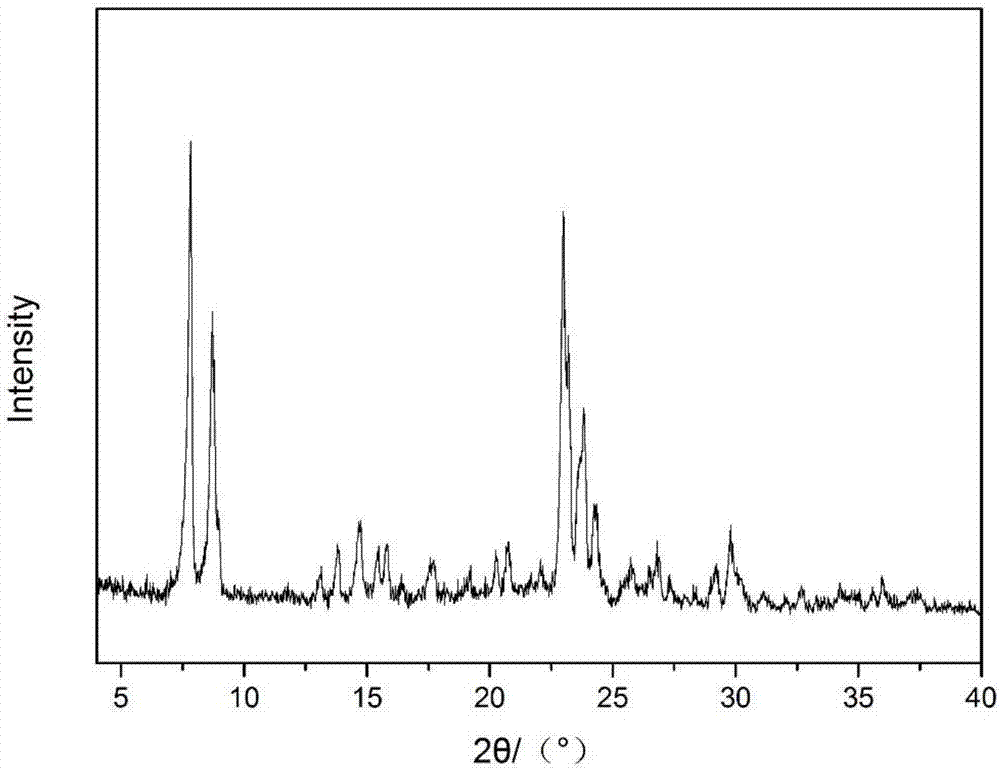

[0035] Preparation of seed crystals:

[0036] (1) 0.416 grams of tetrapropylammonium hydroxide and 5 milliliters of distilled water are added to the reaction vessel, and stirred at room temperature until the two are mixed evenly;

[0037] (2) 3 grams of silica sol (where SiO 2 Quality is 1.2 grams), continue to stir until the two are evenly mixed;

[0038] (3) hydrothermally crystallizing the mixture obtained in step (2) at 150°C for 2 days;

[0039] (4) After cooling to room temperature, the crystallized product is subjected to solid-liquid separation, and the obtained solid is washed with distilled water and dried;

[0040] (5) The dried product is calcined in a muffle furnace at 550° C. for 6 hours, and the product is ball milled for 6 hours after calcination;

[0041] (6) The solid after the ball milling was stirred in an aqueous sodium hydroxide solution of 0.15mol / L for 1 hour, centrifuged, washed with distilled water, and dried at 60° C. for 10 hours to obtain the MFI ...

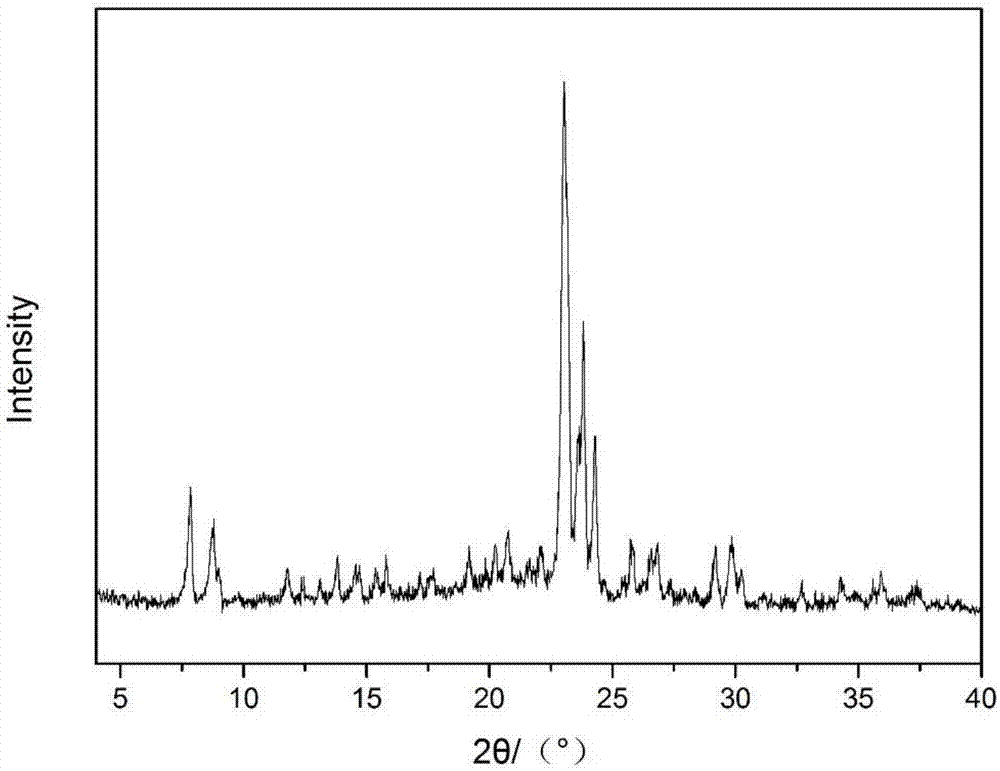

Embodiment 1

[0044] (1) 0.106 gram of tetrapropylammonium bromide and 3.4 milliliters of distilled water are added in the reaction vessel, stirred at room temperature until the two are evenly mixed;

[0045] (2) 3 grams of silica sol (where SiO 2 Quality is 1.2 grams), continue to stir until the solution is mixed evenly;

[0046] (3) Add 0.12 grams of Silicalite-1 molecular sieve seed crystals to the above solution, and stir under airtight and room temperature conditions to form a uniform mixed solution;

[0047] (4) drop into the solution that 0.024 gram of sodium hydroxide and 2 milliliters of distilled waters form in the homogeneous mixed liquor that step (3) forms, and speed is controlled at 1 drop per second. Stir under airtight conditions at room temperature to form a uniform gel, and convert the silicon source into SiO 2 For calculation, the active ingredient composition and molar ratio of the gel are SiO 2 :TPABr:NaOH:H 2 O=100:2:3:1500, the input amount of seed crystal is to c...

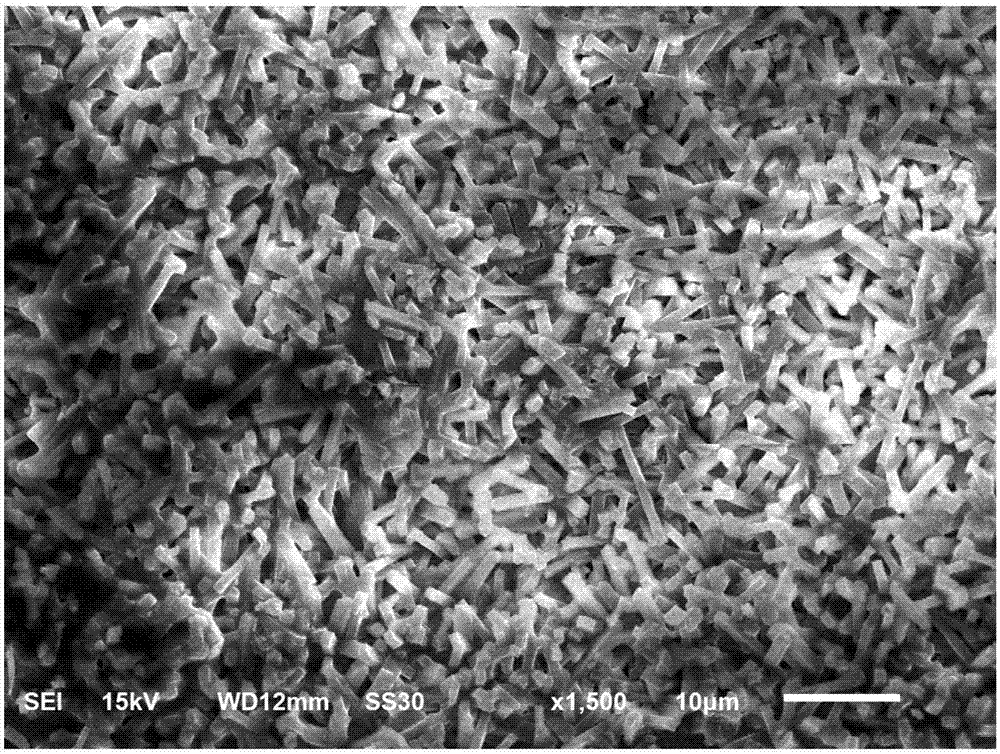

Embodiment 2

[0052] (1) 0.106 gram of tetrapropylammonium bromide and 4 milliliters of distilled water are added in the reaction vessel, stirred at room temperature until the two are evenly mixed;

[0053] (2) 3 grams of silica sol (where SiO 2 Quality is 1.2 grams), continue to stir until the solution is mixed evenly;

[0054] (3) Add 0.12 grams of Silicalite-1 molecular sieve seed crystals to the above solution, and stir under airtight and room temperature conditions to form a uniform mixed solution;

[0055] (4) drop into the solution that 0.016 gram of sodium hydroxide and 2.5 milliliters of distilled waters form in the homogeneous mixed liquor that step (3) forms, and speed is controlled at 1 drop per second. Stir under airtight conditions at room temperature to form a uniform gel, and convert the silicon source into SiO 2 For calculation, the active ingredient composition and molar ratio of the gel are SiO 2 :TPABr:NaOH:H 2 O=100:2:2:1800, the input amount of the seed crystal is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com