Method for preparing high-purity zirconium sulfate tetrahydrate by purifying desilicated zirconia

A zirconium sulfate tetrahydrate and zirconium desiliconization technology, which is applied in the direction of zirconium sulfate and air quality improvement, can solve the problems of cumbersome procedures, environmental pollution, low efficiency, etc., and achieve the goals of avoiding air pollution, low impurity content, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

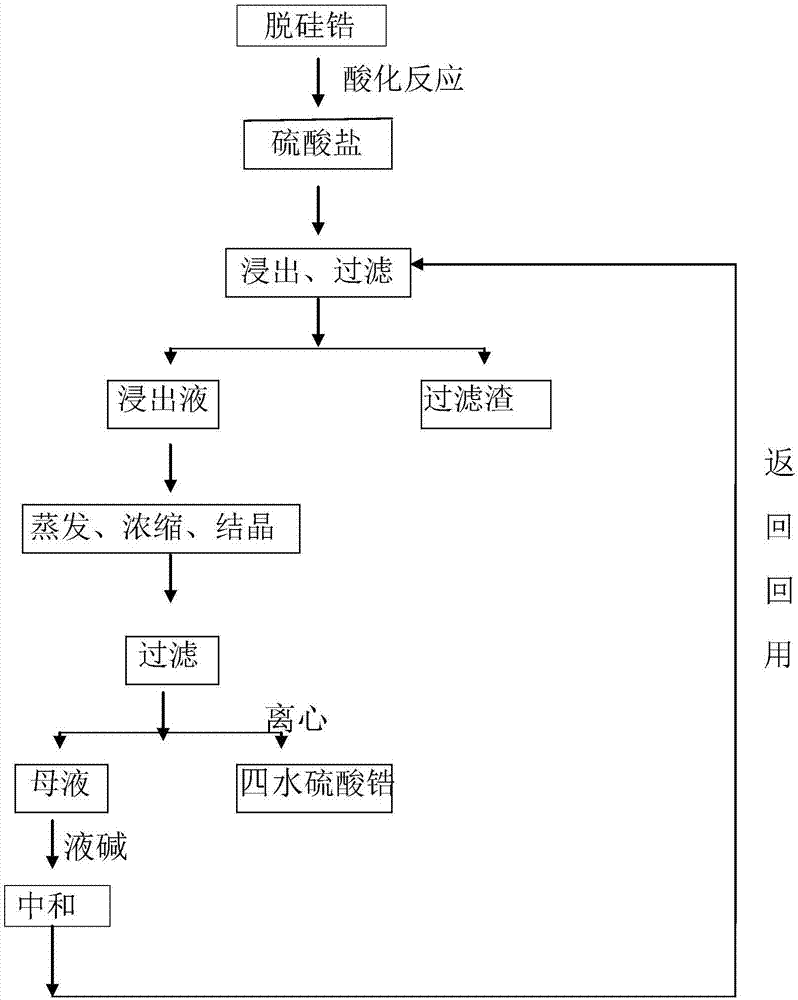

Image

Examples

Embodiment 1

[0033] (1) Ingredients: mix desiliconized zirconium, sodium carbonate and sulfuric acid in a mass ratio of 1:0.1:3;

[0034] (2) Acidification reaction: the above mixture is roasted at 700° C. to make it react to generate sulfate, and the conversion rate is 95%;

[0035] (3) Catalysis: Add sodium carbonate and use its characteristic carbonate to accelerate the boiling reaction;

[0036] (4) Leaching: adding sulfate into water for leaching, the solid-to-liquid ratio is 1:6, the temperature is controlled at 65°C, the acidity is controlled at 7mol / L, and the leaching time is controlled at 2h;

[0037] (5) Press filtration: after the leaching is finished, carry out solid-liquid separation with a plate and frame machine, and press filter to remove the clear liquid;

[0038] (6) Evaporation and concentration: the clear liquid is evaporated and concentrated, and the Baume degree of the concentrated feed liquid is controlled at 30 ° Bé to obtain a concentrated solution;

[0039] (7)...

Embodiment 2

[0045] (1) Ingredients: mix desiliconized zirconium, sodium carbonate and sulfuric acid in a mass ratio of 1:0.2:2.5;

[0046] (2) Acidification reaction: the above mixture is roasted at 800°C to react to generate sulfate, and the conversion rate is 96.5%;

[0047] (3) Catalysis: Add sodium carbonate and use its characteristic carbonate to accelerate the boiling reaction;

[0048] (4) Leaching: add sulfate into water for leaching, the solid-to-liquid ratio is 1:4, the temperature is controlled at 55°C, the acidity is controlled at 5mol / L, and the leaching time is controlled at 3h;

[0049] (5) Press filtration: after the leaching is finished, carry out solid-liquid separation with a plate and frame machine, and press filter to remove the clear liquid;

[0050] (6) Evaporation and concentration: the clear liquid is evaporated and concentrated, and the Baume degree of the concentrated feed liquid is controlled at 37 ° Bé to obtain a concentrated solution;

[0051] (7) Crystall...

Embodiment 3

[0057] (1) Ingredients: mix desiliconized zirconium, sodium carbonate and sulfuric acid according to 1:0.3:3 in parts by mass;

[0058] (2) Acidification reaction: the above mixture is roasted at 830° C. to make it react to generate sulfate, and the conversion rate is 92.8%;

[0059] (3) Catalysis: Add sodium carbonate and use its characteristic carbonate to accelerate the boiling reaction;

[0060] (4) Leaching: add sulfate into water for leaching, the solid-to-liquid ratio is 1:2, the temperature is controlled at 70°C, the acidity is controlled at 8mol / L, and the leaching time is controlled at 2h;

[0061](5) Press filtration: after the leaching is finished, carry out solid-liquid separation with a plate and frame machine, and press filter to remove the clear liquid;

[0062] (6) Evaporation and concentration: the clear liquid is evaporated and concentrated, and the Baume degree of the concentrated feed liquid is controlled at 34 ° Bé to obtain a concentrated solution;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com