Method for continuously producing vinyl-beta-ionol

A technology of ionol and vinyl, applied in chemical instruments and methods, preparation of organic compounds, magnesium chloride, etc., can solve problems such as unmentioned vinyl-β-ionol production process, difficult production process, complicated post-treatment, etc. , to achieve the effect of being suitable for large-scale industrial production, reducing reaction risk, and simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

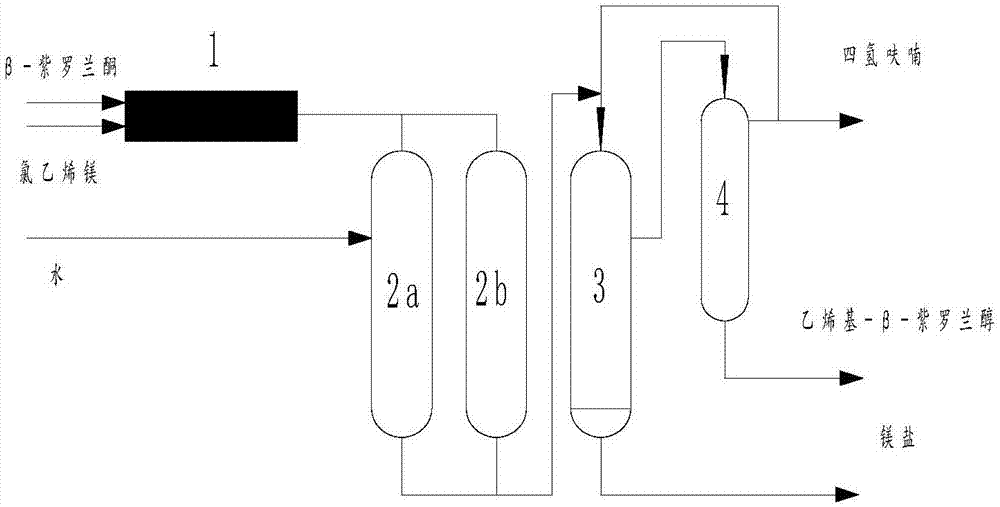

Image

Examples

Embodiment 1

[0051] The tetrahydrofuran solution (molar concentration is 2mol / L, mass fraction is 16.39%) of vinyl chloride magnesium and β-ionone enters in the static mixer with the feed rate of 991.43g / min, 200g / min respectively, and reaction temperature is 5 °C, the residence time is 200s, and the intermediate is obtained from the reaction. After the reaction finishes, the intermediate enters the quenching reactor 2a, and when the reaction solution quality in the reactor 2a is 416kg, it stops feeding to the reactor 2a, and the intermediate enters the quenching reactor 2b, and the reactor 2a begins to feed at 140g / min Add 40kg of water at a high speed to quench, and the quenching temperature is 5°C. After the quenching is completed, move the product to a centrifugal filter and filter it with a 1500-mesh filter cloth, separate the filtrate at a speed of 600rmp, and centrifuge to obtain basic magnesium chloride and filtrate ethylene. The tetrahydrofuran solution of β-ionol, the filter cake...

Embodiment 2

[0053]The tetrahydrofuran solution of magnesium vinyl chloride (molar concentration is 1mol / L, mass fraction is 8.9%) and β-ionone are entered in the static mixer with the feed rate of 1520g / min, 200g / min respectively, and the reaction temperature is 5 ℃ , the residence time is 500s, and the intermediate is obtained from the reaction. After the reaction finishes, the intermediate enters the quenching reactor 2a, and when the reaction liquid quality in the still is 601kg, stop feeding to the reactor 2a, the intermediate enters the quenching reactor 2b, and the reactor 2a begins to add 59kg at 200g / min Quenching with water, the quenching temperature is -2°C, after the quenching is completed, move the product to a centrifugal filter and filter it with a 3000-mesh filter cloth, separate the filtrate at a speed of 1000rmp, and centrifuge to obtain basic magnesium chloride and filtrate vinyl-β -The tetrahydrofuran solution of ionol, filter cake basic magnesium chloride adds 29kg tet...

Embodiment 3

[0055] The tetrahydrofuran solution (molar concentration is 1.5mol / L, 12.8%) of vinyl chloride magnesium and β-ionone enter in the static mixer with the feed rate of 775g / min, 200g / min respectively, and reaction temperature is 1 ℃, stops The time is 600s, and the intermediate is obtained from the reaction. After the reaction finishes, the intermediate enters the quenching reactor 2a. When the reaction liquid quality in the still is 426kg, it stops feeding to the reactor 2a, the intermediate enters the quenching reactor 2b, and the reactor 2a begins to add 72kg at 400g / min. Water is used for quenching, and the quenching temperature is -5°C. After quenching, the product is transferred to a centrifugal filter and filtered with a 2000-mesh filter cloth. The filtrate is separated at a speed of 600rmp, and centrifuged to obtain basic magnesium chloride and filtrate vinyl-β -The tetrahydrofuran solution of ionol, the basic magnesium chloride of filter cake adds 19.1kg tetrahydrofuran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com