Patents

Literature

108 results about "Beta-ionone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ionone Beta has a particularly intense freesia character. The volume of Ionone Beta is emphasized by a fruity, somewhat raspberry-like background. Usage: It is useful in the formulation of boronia and indispensable in violet compositions. It has good substantivity and is used in all areas of perfumery.

Method for preparing tobacco-characteristic-taste tobacco flavor material and electronic cigarette fluid containing tobacco flavor material

ActiveCN105595411ACapture completelyImprove qualityTobacco treatmentEssential-oils/perfumesDistillationLiquid smoke

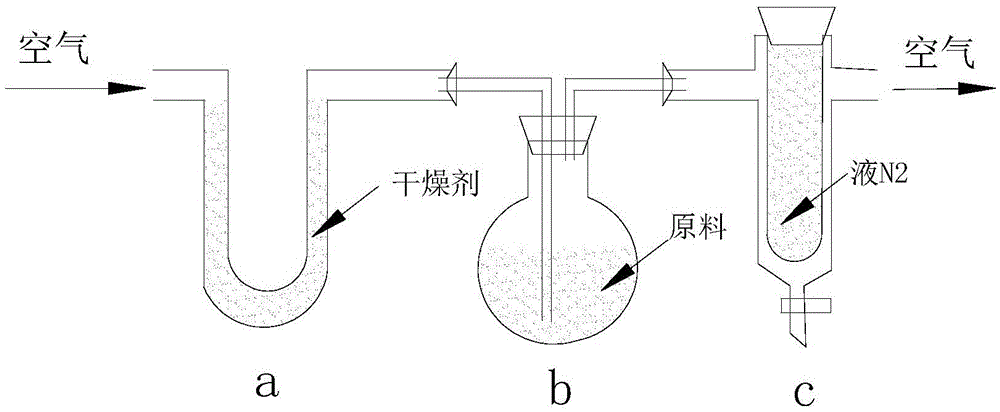

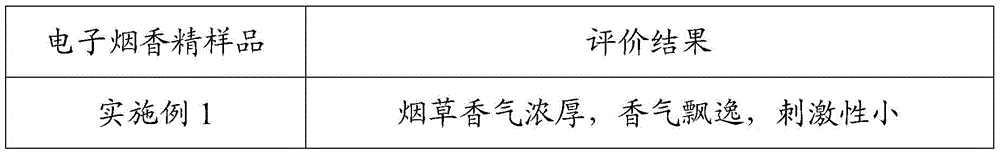

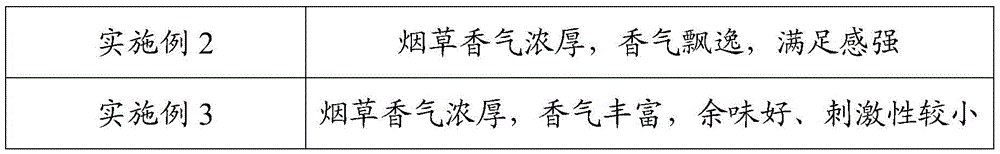

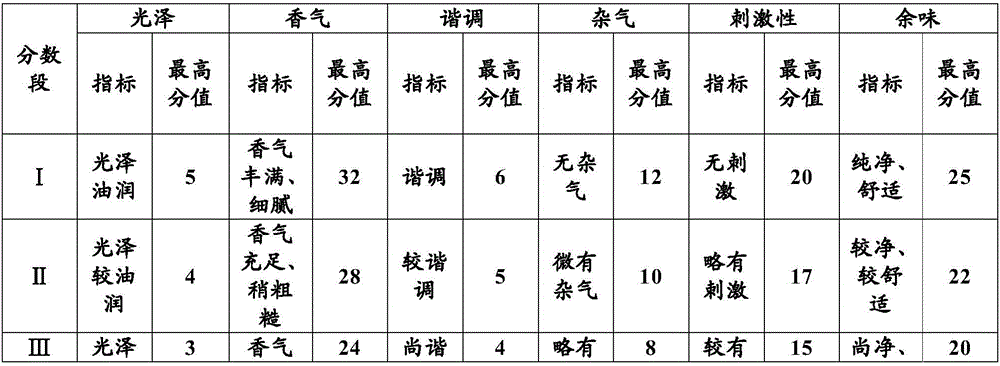

The invention provides a method for preparing a tobacco-characteristic-taste tobacco flavor material. The method comprises the following steps of choosing a raw tobacco material as a backing material, evenly spraying an atomizing agent on the surface of the raw tobacco material, standing, putting the backing material into a dry distilling device after the backing material is fully infiltrated by the atomizing agent, distilling the backing material under the temperature between 150 DEG C and 300 DEG C to obtain aromatic components, inducing dry air into the dry distilling device in distillation and catching the aromatic components through a condensing device to obtain the tobacco flavor material. The invention further provides electronic tobacco fluid which comprises basic tobacco fluid formed by essences, nicotine, glycerinum and propylene glycol in a mixing manner. The flycerinum and the propylene glycol serve as solvents, the tobacco flavor material and tobacco extracts are added into the basic tobacco fluid, the tobacco extracts comprise a red sun-cured tobacco reactant and a Zimbabwe tobacco extractive, and the essences comprise ethyl maltol and 2(H) beta-ionone. According to the tobacco flavor material prepared through a dry distilling-condensing catching method, a preparing process of the tobacco flavor material is closer to a burning and smoking process of traditional cigarettes, and the smoking taste of the tobacco flavor material is closer to the smoking taste of the traditional cigarettes.

Owner:HUBEI CHINA TOBACCO IND

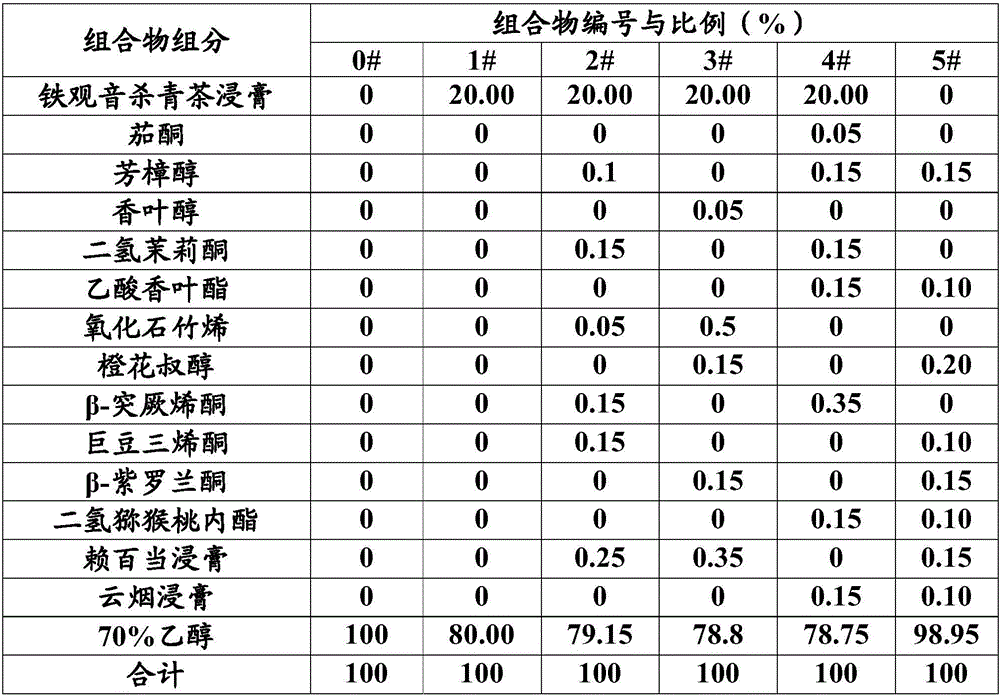

Composition and application of composition in cigarettes

InactiveCN105969524AElegant aromaDelicate and elegant aromaTobacco preparationEssential-oils/perfumesNerolidolBeta-damascenone

The invention provides a composition and application of the composition in cigarettes and particularly provides a composition. The composition contains a main flavor enhancer, a coordination agent, a modifier and a fixative, wherein the main flavor enhancer is an extract of a preliminary tea product, the coordination agent is tomato ketone, linalool, geraniol, dihydrogen jasmone, geranyl acetate or any combination thereof, the modifier is caryophyllene oxide, nerolidol, beta-damascenone, megastigmatrienone, beta-ionone, dihydro kiwifruit lactone or any combination thereof, and the fixative is a ladanum extract, a Yunyan tobacco extract or a combination thereof. The composition has an elegant and natural aroma, is fresh and fragrant, has a sweet, fragrant and graceful smell and can be widely used in the fields of tobaccos, foods and daily chemicals and the like.

Owner:CHINA TOBACCO FUJIAN IND

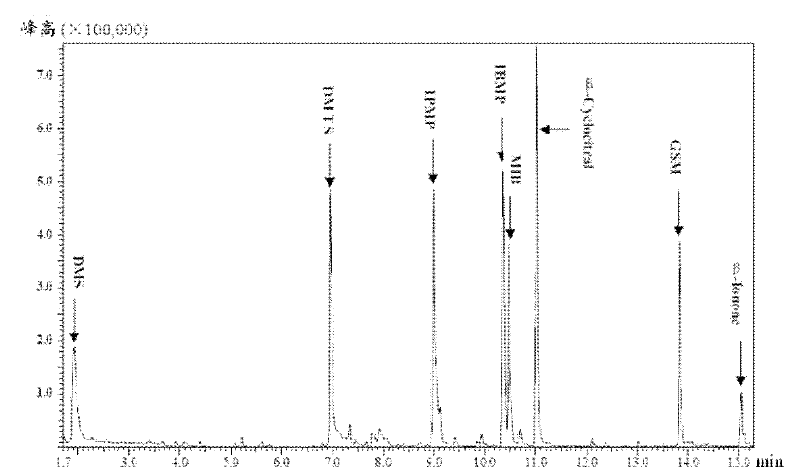

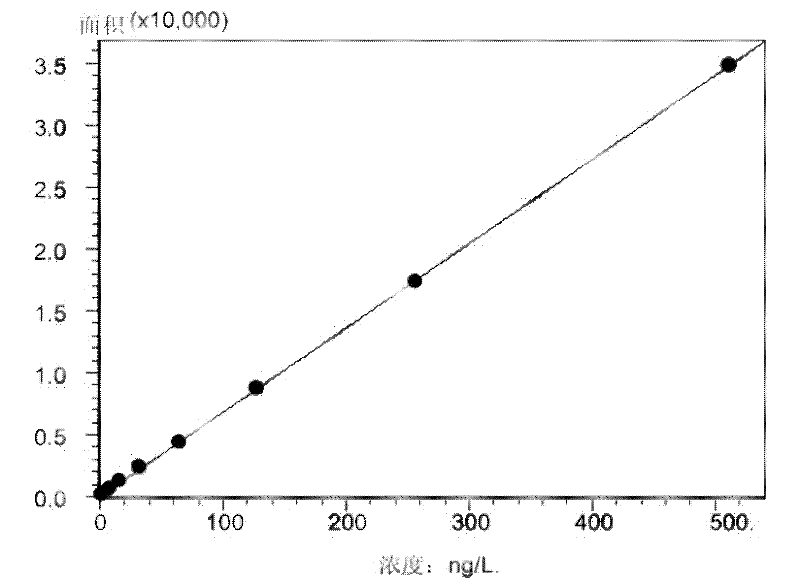

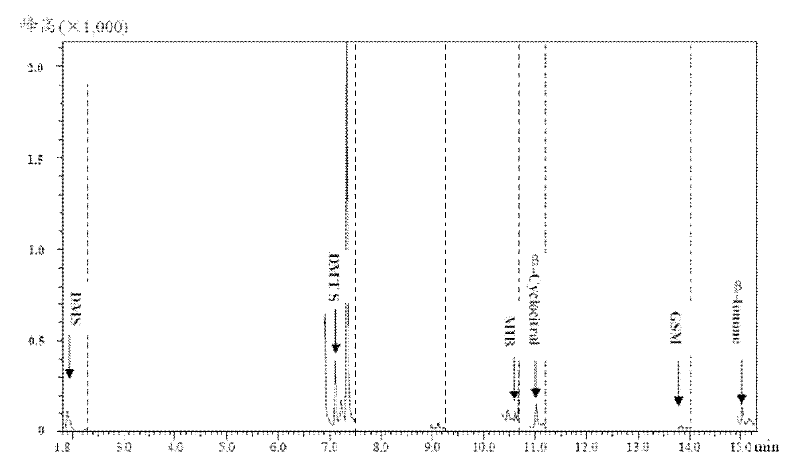

Method for determining eight kinds of odorous substances in water simultaneously

InactiveCN102253156AHigh degree of automationReduce detection efficiencyComponent separationPyrazineWater quality

The invention belongs to the technical field of natural environment water quality monitoring and discloses a method for determining eight kinds of common odorous substances in water simultaneously through use of a method of combining purge-and-trap and gas chromatography / mass spectrometry. The method can be adopted to determine eight kinds of common odorous substances such as dimethyl sulfide (DMS), dimethyl trisulfide (DMTS), 2-isopropyl-3-methoxy pyrazine (IPMP), 2-isobutyl-3-methoxy pyrazine (IBMP), 2-methyl isobornyl (MIB), beta-cyclocitral, geosmin (GSM) and beta-ionone in water simultaneously. Any report on the method for determining the eight kinds of substances in one step is not present yet. The method disclosed by the invention fills the gap and can be used for quantitatively analyzing the eight kinds of odorous substances in water in one step, so that the detection efficiency is greatly increased.

Owner:INST OF AQUATIC LIFE ACAD SINICA

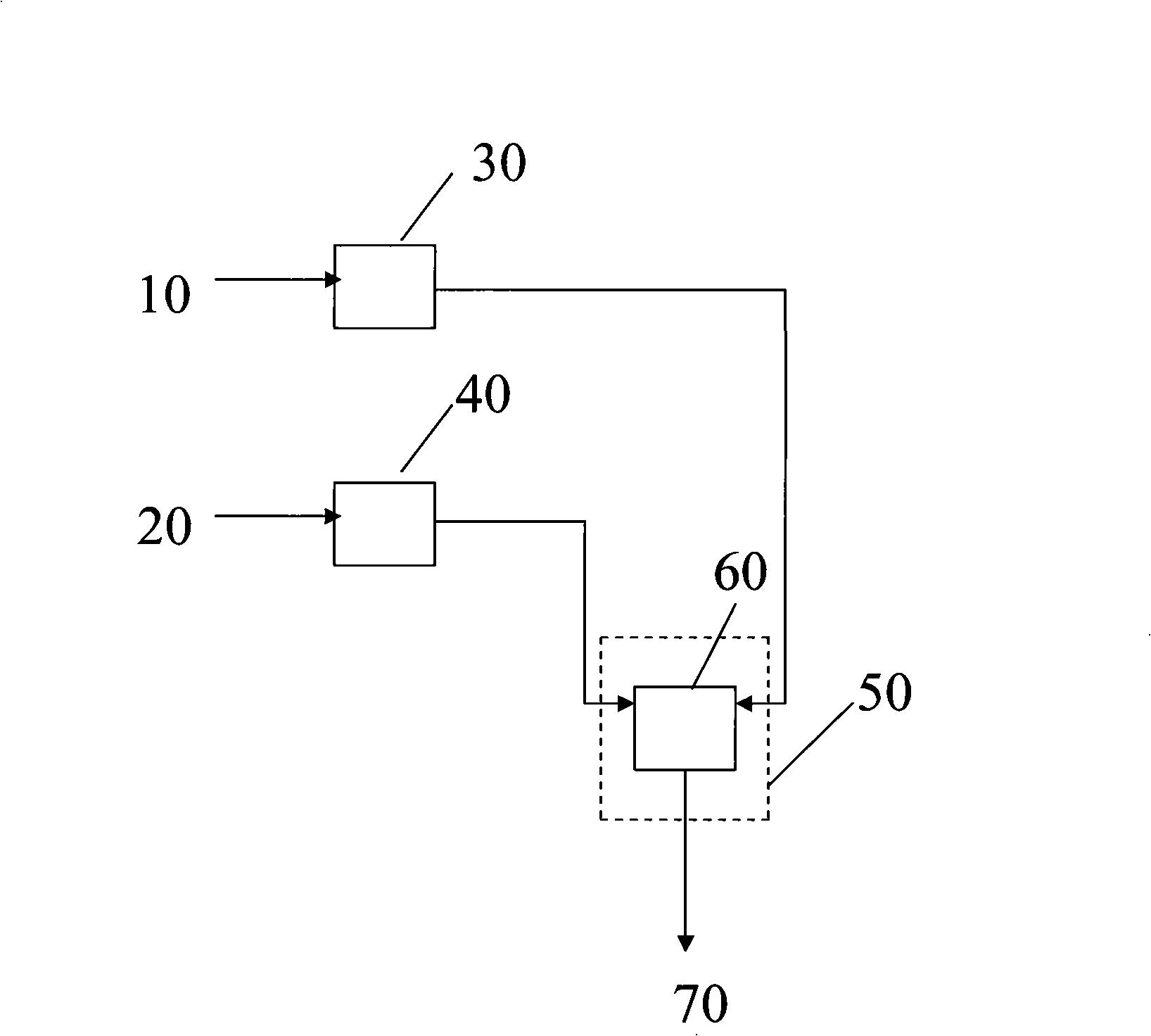

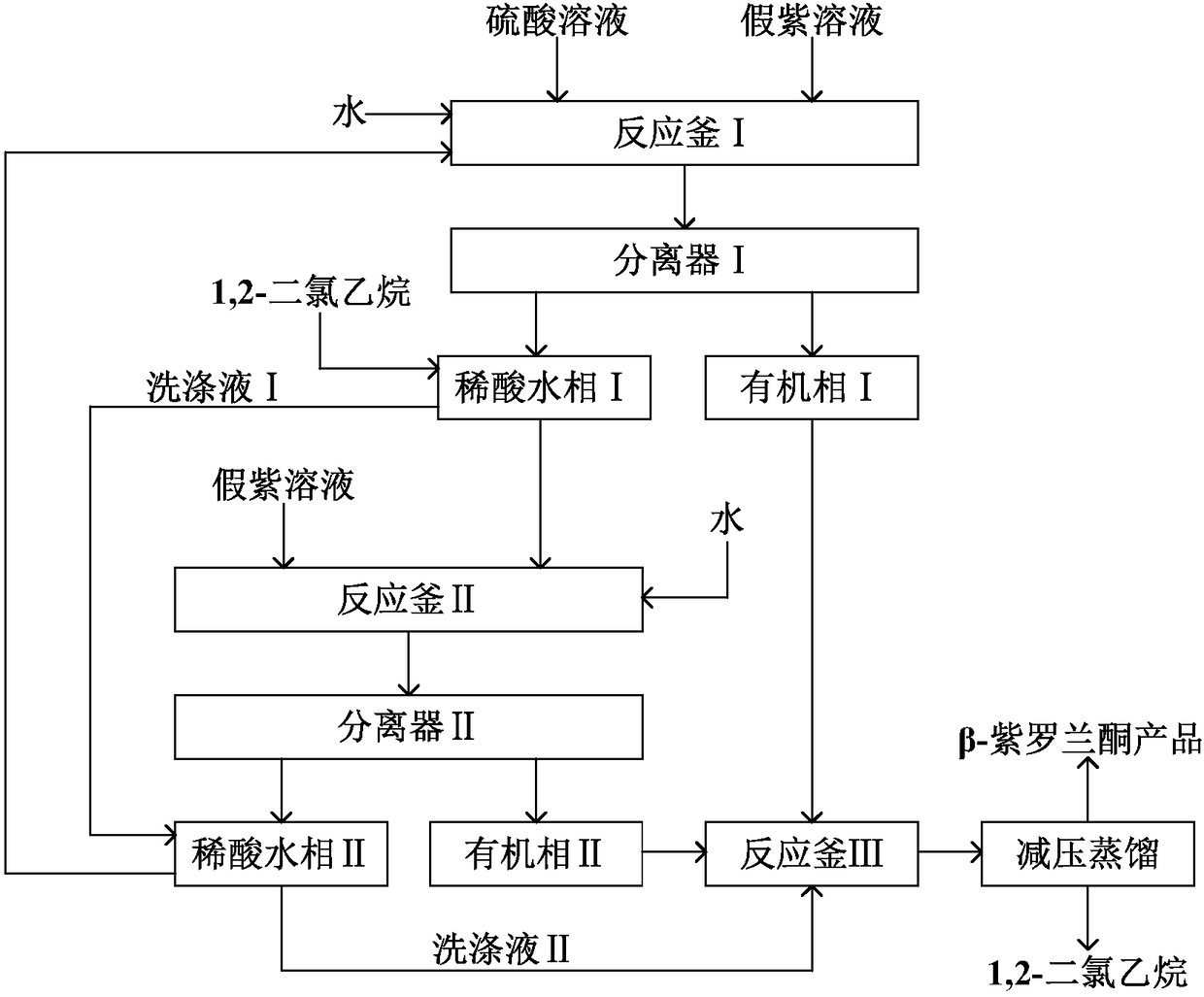

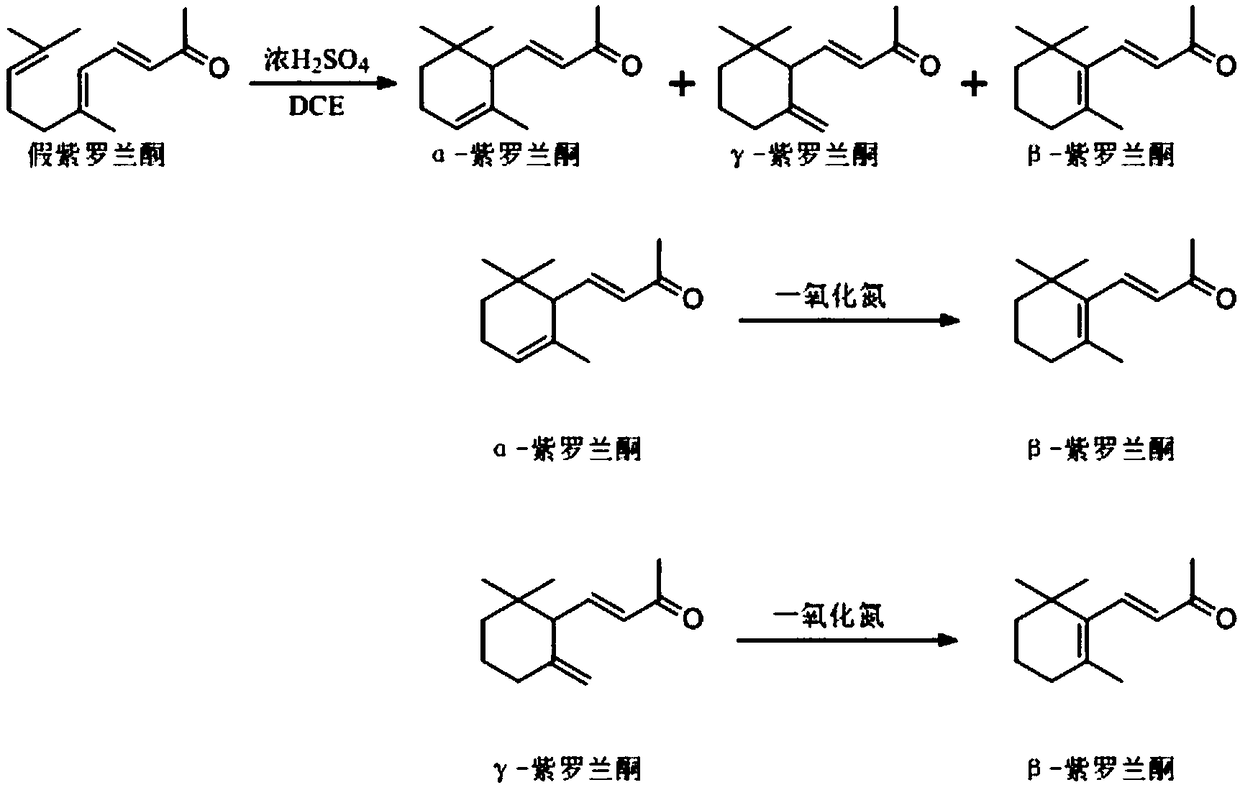

Method for synthesizing beta-ionone

InactiveCN101333154AIncrease the number ofEasy to adjust controlOrganic compound preparationCarbonyl compound preparationSynthesis methodsChemistry

The invention relates to a method for synthesizing beta-ionone, in particular to a method which uses a micro-reactor and takes concentrated sulfuric acid as catalyst to continuously synthesize beta-ionone through cyclization reaction to pseudoionone. The synthesis method can effectively suppress side effects; the selectivity of the beta-ionone in the product is 90-97 wt%.

Owner:BAYER TECH & ENG SHANGHAI

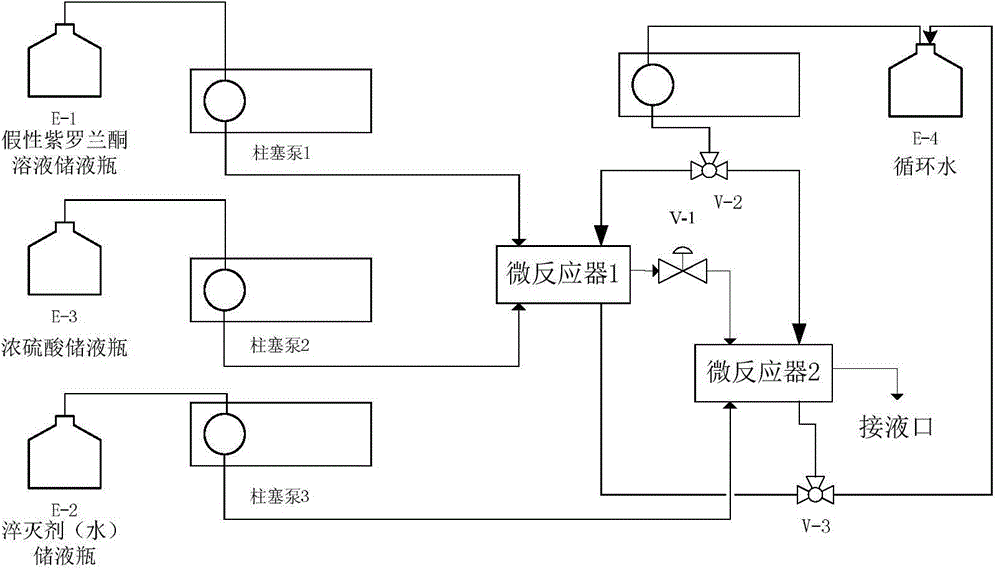

Method for continuously synthesizing beta-ionone through micro-chemical engineering technology

ActiveCN106278853ASave low temperature energy consumptionReduce consumptionOrganic compound preparationCarbonyl compound preparationEmulsionIce water

The invention relates to a method for continuously synthesizing beta-ionone from pseudoionone through applying a micro-chemical engineering technology. The method comprises the following steps: solvent diluted pseudoionone and concentrated sulfuric aid continuously go through a micro-reaction and micro-heat exchange integrated micro-1reactor 1 and undergo reaction and heat exchange in the channel of the micro-reactor to generate the beta-ionone product; and a reaction mixture which is an acid-in-oil micro-emulsion system flows through a micro-reaction and micro-heat exchange integrated micro-1reactor 2, and is diluted by ice water according to a certain volume ratio in order to realize convenient subsequent workshop treatment. Reaction parameters are accurately controlled through a micro-channel technology in the invention, so the yield of the beta-ionone can reach 80-85%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Essence with red bean fragrance and preparation method thereof

InactiveCN106490574ASoft and delicate aromaOutstanding characteristic aromaFood scienceEthyl butyrateDamascone

The invention relates to an essence with red bean fragrance. The essence with red bean fragrance is composed of: isoamyl acetate with a mass percentage concentration of 1%, ethyl butyrate with a mass percentage concentration of 1%, beta-damascone, beta-ionone with a mass percentage concentration of 1%, 2-methylpyrazine with a mass percentage concentration of 1%, 2, 5-dimethylpyrazine, 2-acetylpyrazine with a mass percentage concentration of 1%, melonal, 4-ketoisophorone, ethyl maltol, thiol, menthyl acetate, menthol with a mass percentage concentration of 1%, vanillin, ethyl vanillin with a mass percentage concentration of 1%, vanillin propylene glycol acetal, 2-methoxy-3-isobutyl pyrazine with a mass percentage concentration of 1%, and a solvent. The raw materials are added into a container in order according to the formula and are stirred evenly to obtain the essence with red bean fragrance. The essence provided by the invention has outstanding characteristic fragrance of red beans, has strong natural feel and harmonious, soft and delicate fragrance, and can be used for perfuming of drinks, pastries and other food.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

Method for synthesizing beta-ionone

InactiveCN1483713AMild reaction conditionsThe separation method is simpleMolecular sieve catalystsOrganic compound preparationRotary evaporatorDistillation

Under the condition of constant temperature the prepared solid super acidic catalyst is added into the acetone solution, under the protection of nitrogen gas the pseudo ionone can be slowly added while stirring, after the reaction is completed, the solid super acidic catalyst is fertered and separated, then the acetone can be separated out in rotary evaporator, finally, the target product beta-ionone can be separated out by utilizing reduced pressure distillation process.

Owner:SHANGHAI JIAO TONG UNIV

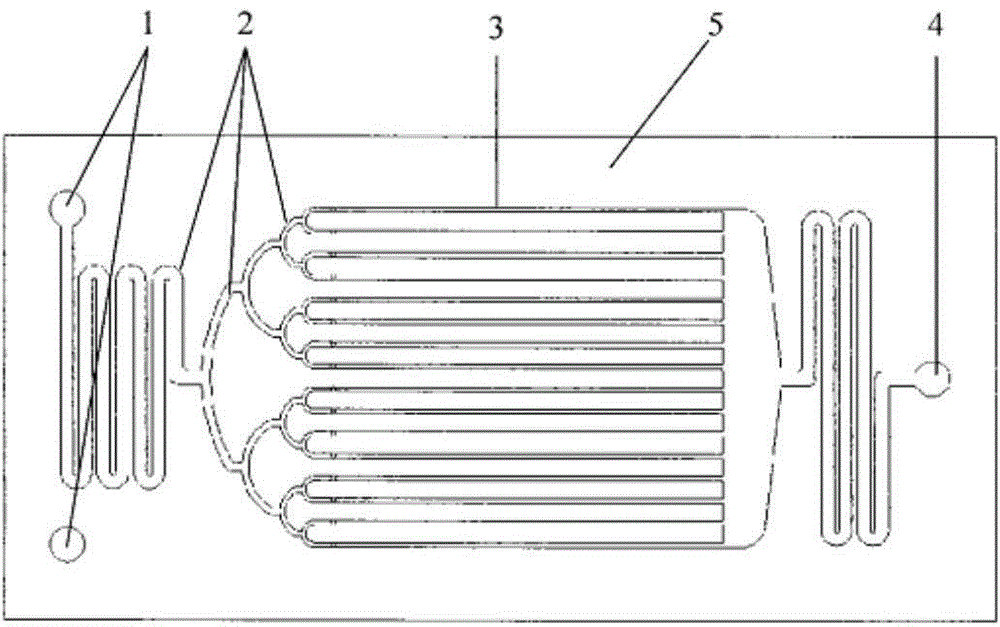

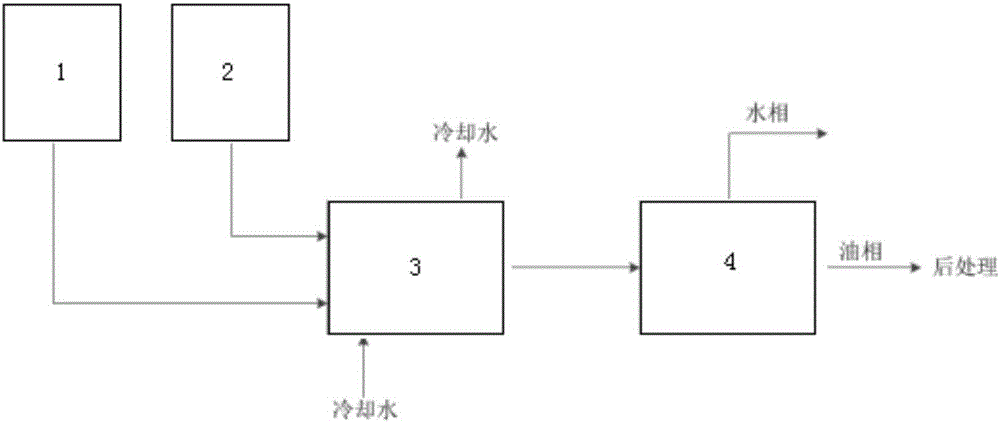

Device and method for continuously producing beta-ionone by using microchannel

PendingCN106673980AHigh yieldImprove heat transfer efficiencyOrganic compound preparationChemical/physical/physico-chemical microreactorsOrganic solventPhase splitting

The invention discloses a device and method for continuously producing beta-ionone by using microchannel. The method comprises the following steps: preparing a pseudoionone organic solvent into a pseudoionone solution in volume percentage of 30-70%, adding the pseudoionone solution and concentrated sulfuric acid into a microchannel reactor respectively through two inlets of the microchannel reactor, reacting at a temperature of 25-30 DEG C, enabling reactant to flow out of the microchannel reactor, carrying out phase splitting treatment on the reactant by using a phase splitter to obtain a water phase and an oil phase containing beta-ionone, and treating the oil phase containing beta-ionone to obtain beta-ionone oily liquid. The method is convenient to operate and easily controllable in condition; the produced beta-ionone is high in yield and high in purity; the large-scale industrial production is facilitated; the microchannel reactor has extremely high heat exchange efficiency and is capable of preventing local temperature from excessively high, eliminating hot-spot temperature and improving the purity of the product which is beta-ionone; the continuous product is achieved; the production efficiency is improved; the copious cooling condition is avoided; the energy consumption is reduced; the cost is reduced.

Owner:SHANGHAI FLUKO TECH DEV

Method for preparing beta-ionone by using pseudoionone as raw materials

ActiveCN108329200AHigh purityIncrease profitOrganic compound preparationOrganic chemistry methodsIsomerizationNitric oxide gas

The invention discloses a method for preparing beta-ionone by using pseudoionone as raw materials. The pseudoionone performs cyclization reaction under the catalysis effect of sulfuric acid; quenchingis performed; nitric oxide gas is introduced into reaction liquid after the quenching; then, isomerization reaction is performed to obtain the beta-ionone. The method has the advantages that the process is simple; no harsh reaction conditions are needed; sulfuric acid and solvents can be cyclically used for many times; in addition, the purity of the beta-ionone in the obtained product is high, and is higher than 97.5 percent.

Owner:WANHUA CHEM GRP CO LTD

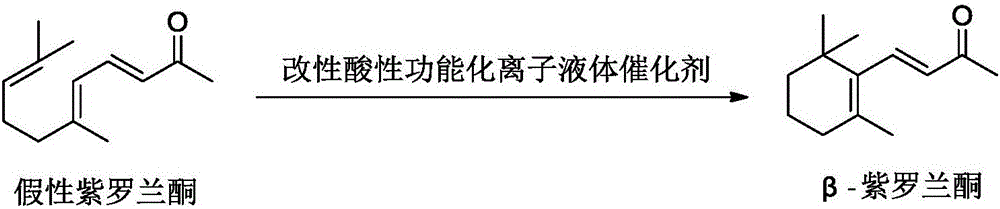

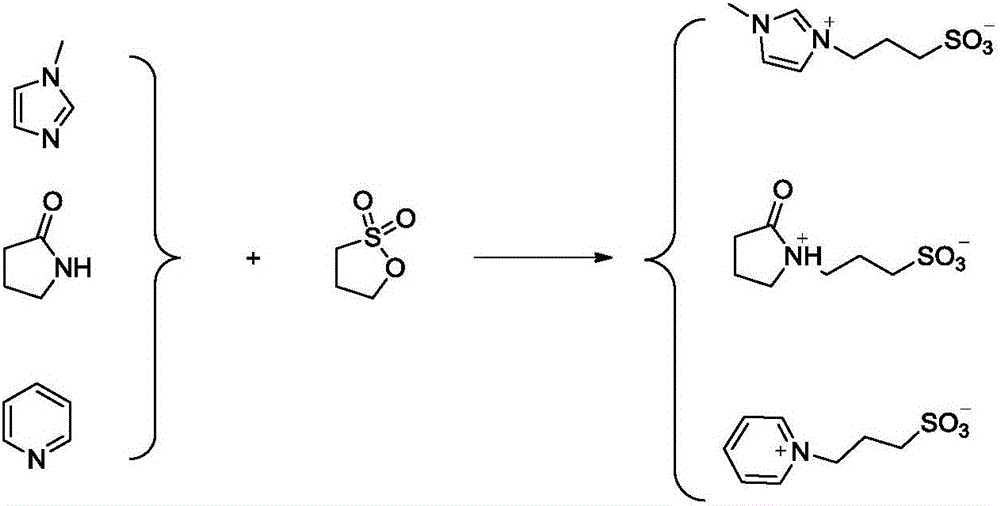

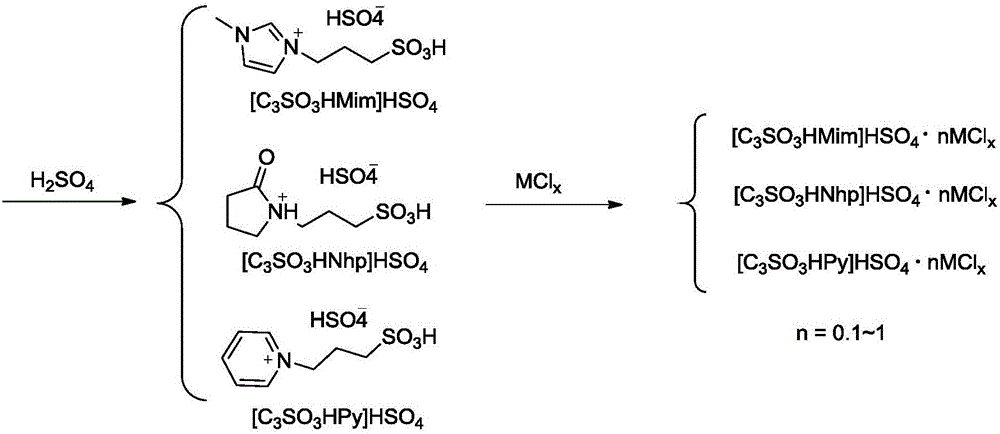

Method for preparing beta-ionone from modified acidic functionalized ionic liquid

ActiveCN106496006AHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIononeIonic liquid

The invention relates to a method for preparing beta-ionone from modified acidic functionalized ionic liquid. The method includes the following steps that the modified acidic functionalized ionic liquid serves as a catalyst, and pseudo ionone is cyclized into beta-ionone. The modified acidic functionalized ionic liquid serves as the catalyst, the high reactive transformation rate and beta-ionone yield are achieved, the reactive transformation rate reaches 99% or above, and the beta-ionone yield reaches 94% or above. The catalyst can still keep the high transformation rate and yield after being separated and applied mechanically multiple times, the reactive transformation rate still reaches 99% or above, and the reaction yield is still kept at 90% or above.

Owner:WANHUA CHEM GRP CO LTD

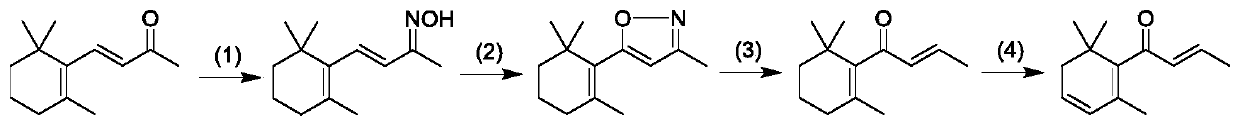

Preparation method of beta-damascenone spice

ActiveCN104003860ASimple and fast operationMild reaction conditionsOrganic compound preparationOximes preparationHydroxylamine HydrochlorideSolvent

The invention discloses a preparation method of beta-damascenone spice. The preparation method comprises the following steps: (1) by taking beta-ionone as an initial raw material, carrying out a reaction with hydroxylamine hydrochloride in an alkaline environment to obtain beta-ionone oxime; (2) carrying out a reaction on beta-ionone oxime and halogens and metal salt thereof to obtain a beta-ionone oxime isoxazole derivative; (3) acting on the eta-ionone oxime isoxazole derivative and sodium to generate beta-dihydrodamascenone; and (4) carrying out an oxidizing halogenating reaction on beta-dihydrodamascenone and free radicals of halogens and carrying out an elimination reaction of removing halogen hydride under the alkaline environment to obtain the beta-damascenone. The preparation method disclosed by the invention is cheap and easily available in raw materials, simple to operate, mild in reaction condition, high in yield of reactions and low in cost, and the solvent used can be recycled, so that the preparation method is a method suitable for industrially producing beta-damascenone spice.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Black tea flavor

The invention provides black tea flavor, which comprises the following components in percentage by weight: 0.01 to 1 percent of beta-ionone alcohol solution and 0.05 to 5 percent of salicylic methyl ester alcohol solution in terms of total weight of the flavor. By adding a beta-ionone carotinoid decomposer into the conventional black tea flavor, a sumptuous black tea beverage can be manufactured; and the further added salicylic methyl ester can show the characteristic of the black tea more remarkably.

Owner:长谷川香料(上海)有限公司

Honey peach-flavored essence formulation

InactiveCN109135925AStrong creamy fatty smellIncrease aromaEssential-oils/perfumesPropanoic acidPeach Flavor

The invention discloses a honey peach-flavored essence formulation, comprising, by weight, 1.00-3.00% of ethyl butyrate, 0.50-0.80% of leaf alcohol, 0.50-0.80% of propyl butyrate, 0.20-0.50% of benzaldehyde, 1.00-3.0% of butyl isovalerate, 0.20-0.50% of beta-ionone, 0.20-0.50% of alpha-ionone, 0.50-0.80% of gamma-decalactone, 0.50-0.80% of peach aldehyde, 0.30-0.80% of propionic acid, 0.60-0.90% of cis-3-hexenyl isobutyrate, 0.50-0.80% of 5-decanolide, 0.50-0.80% of ethyl maltol, and 93.50-98.50% of propylene glycol. By adding 8-mercaptomenthone, undecanolactone and gamma-octalactone, the aroma of the honey peach-flavored essence can be greatly improved; by adding 8-mercaptomenthone in a certain ratio, the aroma of undecanolactone can be neutralized and can be more natural, softer and morepopular with people; by adding gamma-octalactone in a certain ratio, the taste of the honey peach-flavored essence can be more mellow.

Owner:双凯食品配料(昆山)有限公司

Process for Synthesis of (3S)- and (3R)-3-Hydroxy-Beta-Ionone, and Their Transformation to Zeaxanthin and Beta-Cryptoxanthin

InactiveUS20090311761A1High yieldOrganic compound preparationCarbonyl compound preparationMetaboliteIsomerization

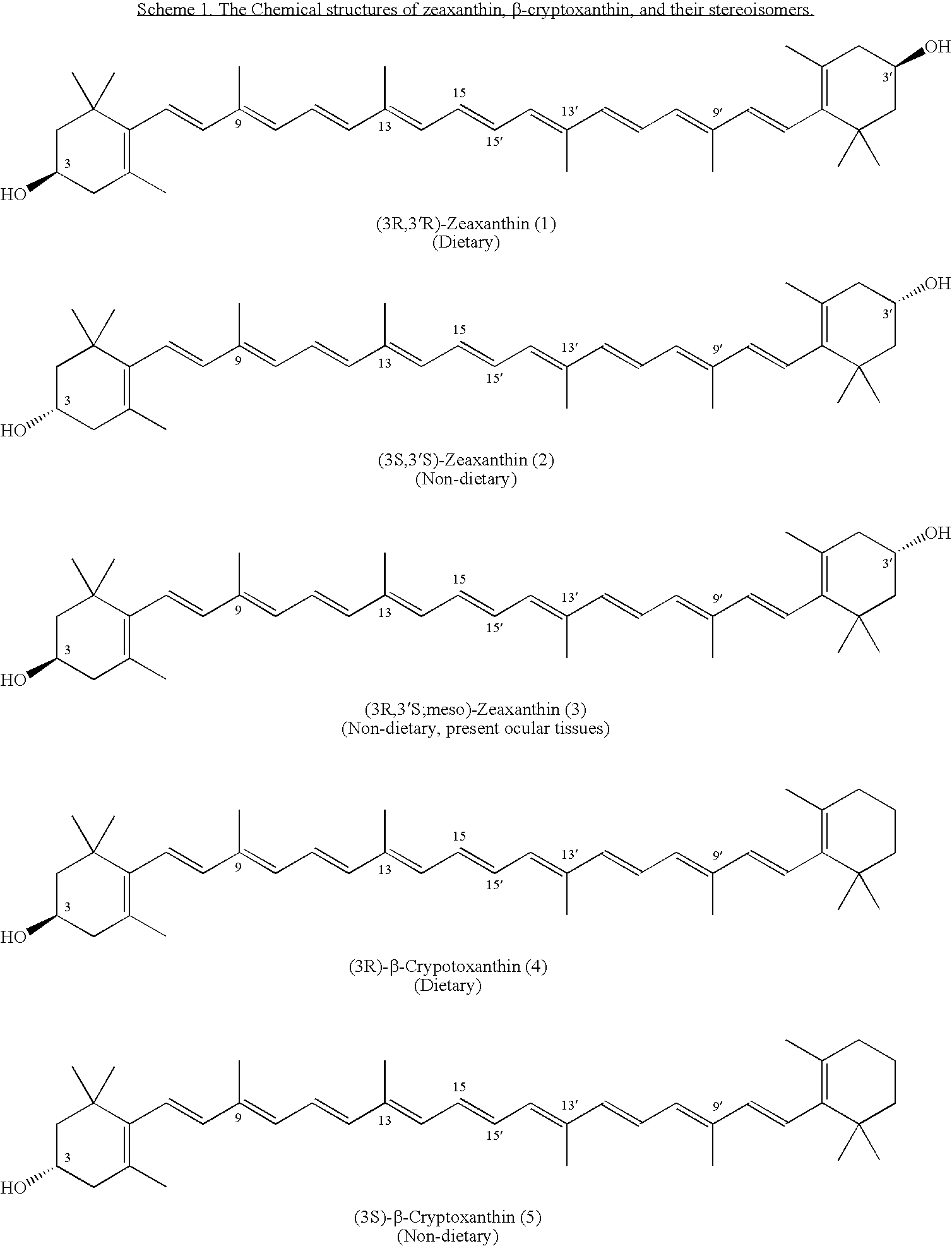

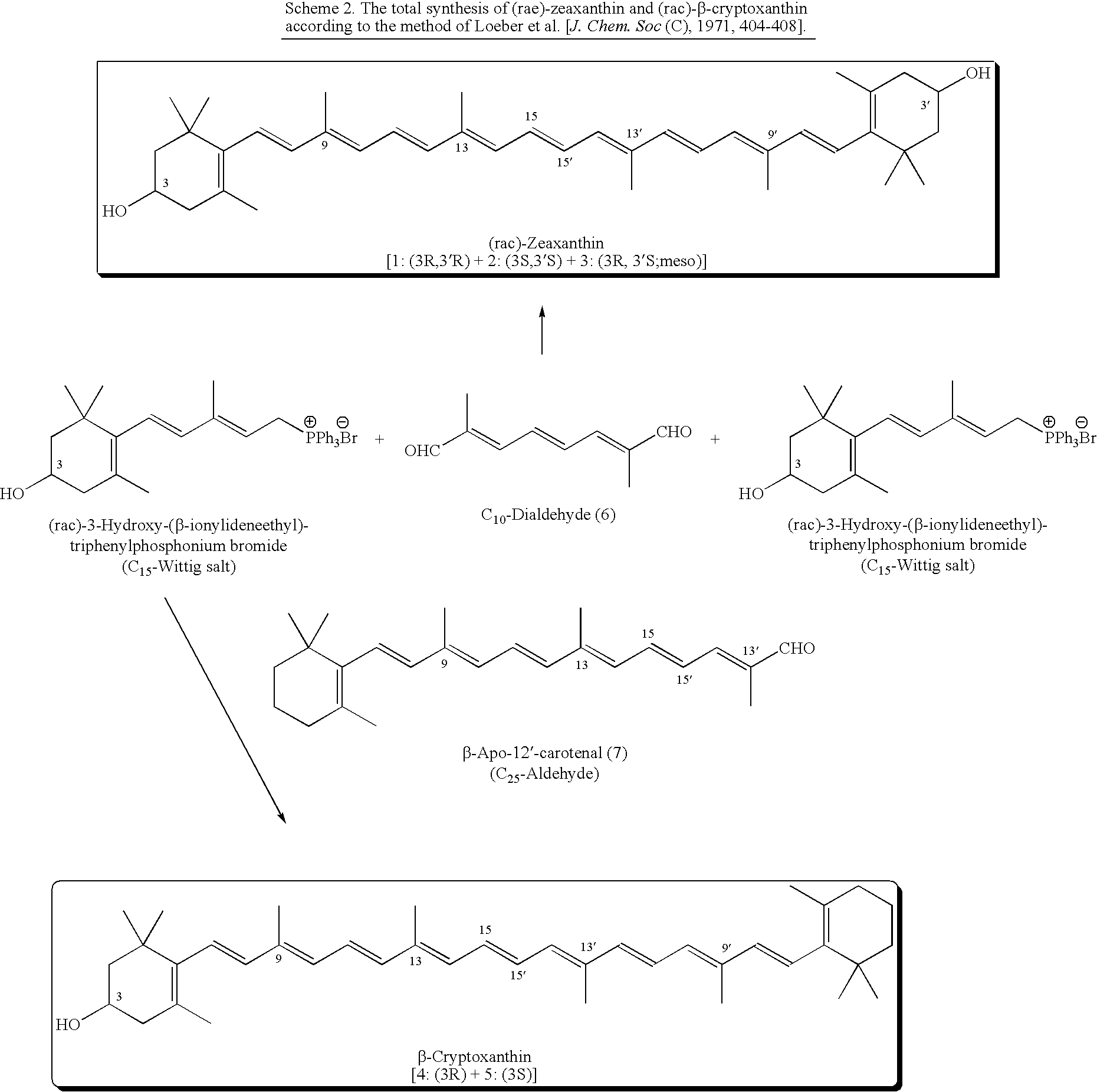

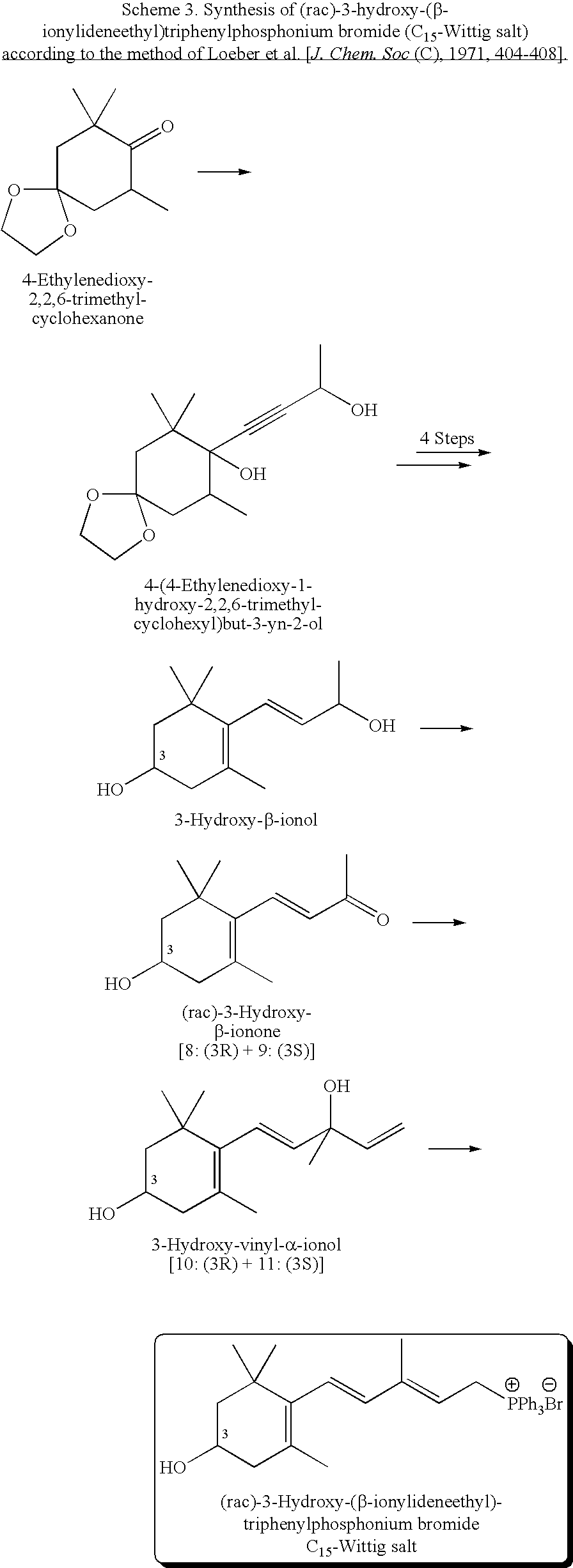

(3R)-3-Hydroxy-β-ionone and (3S)-3-hydroxy-β-ionone are two important intermediates in the synthesis of carotenoids with β-end group such as lutein, zeaxanthin, β-cryptoxanthin, and their stereoisomers. Among the various stereoisomers of these carotenoids, only (3R,3′R,6′R)-lutein, (3R,3′R)-zeaxanthin, and (3R)-β-cryptoxanthin are present in commonly consumed fruits and vegetables. There are 3 possible stereoisomers for zeaxanthin, these are: dietary (3R,3′R)-zeaxanthin (1), non-dietary (3S,3′S)-zeaxanthin (2), and non-dietary (3R,3′S;meso)-zeaxanthin (3) which is a presumed metabolite of dietary lutein. Dietary lutein as well as 1 and 3 are accumulated in the human macula and have been implicated in the prevention of age-related macular degeneration. (3R)-β-Cryptoxanthin (4) is also present in selected ocular tissues at a very low concentration whereas its enantiomer (3S)-β-cryptoxanthin (5) is absent in foods and human plasma.The present invention relates to a process for the synthesis of (3R)-3-hydroxy-β-ionone and its (3S)-enantiomer in high optical purity from commercially available (rac)-α-ionone. The key intermediate for the synthesis of these hydroxyionones is 3-keto-α-ionone ketal that was prepared from (rac)-α-ionone after protection of this ketone as a 1,3-dioxolane. Reduction of 3-keto-α-ionone ketal followed by deprotection, lead to 3-hydroxy-α-ionone that was transformed into (rac)-3-hydroxy-β-ionone by base-catalyzed double bond isomerization in 46% overall yield from (rac)-α-ionone. The racemic mixture of these hydroxyionones was then resolved by enzyme-mediated acylation in 96% ee. (3R)-3-Hydroxy-β-ionone and its (3S)-enantiomer were respectively transformed to (3R)-3-hydroxy-(β-ionylideneethyl)triphenylphosphonium chloride [(3R)—C15-Wittig salt] and its (3S)-enantiomer [(3S)—C15-Wittig salt] according to known procedures. Double Wittig condensation of these Wittig salts with commercially available 2,5-dimethylocta-2,4,6-triene-1,8-dial provided all 3 stereoisomers of zeaxanthin (1-3). Similarly, (3R)—C15-Wittig and its (3S)-enantiomer were each coupled with β-apo-12′-carotenal to yield 4 and 5.

Owner:UNIV OF MARYLAND

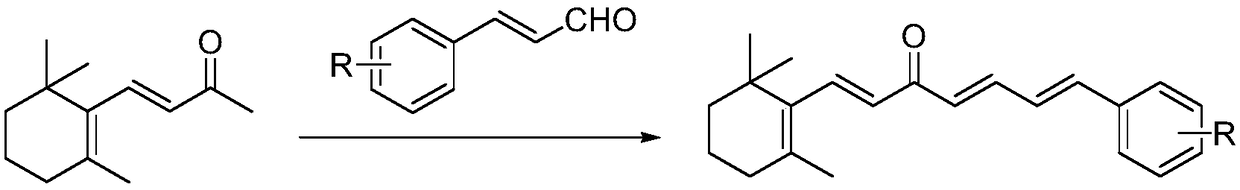

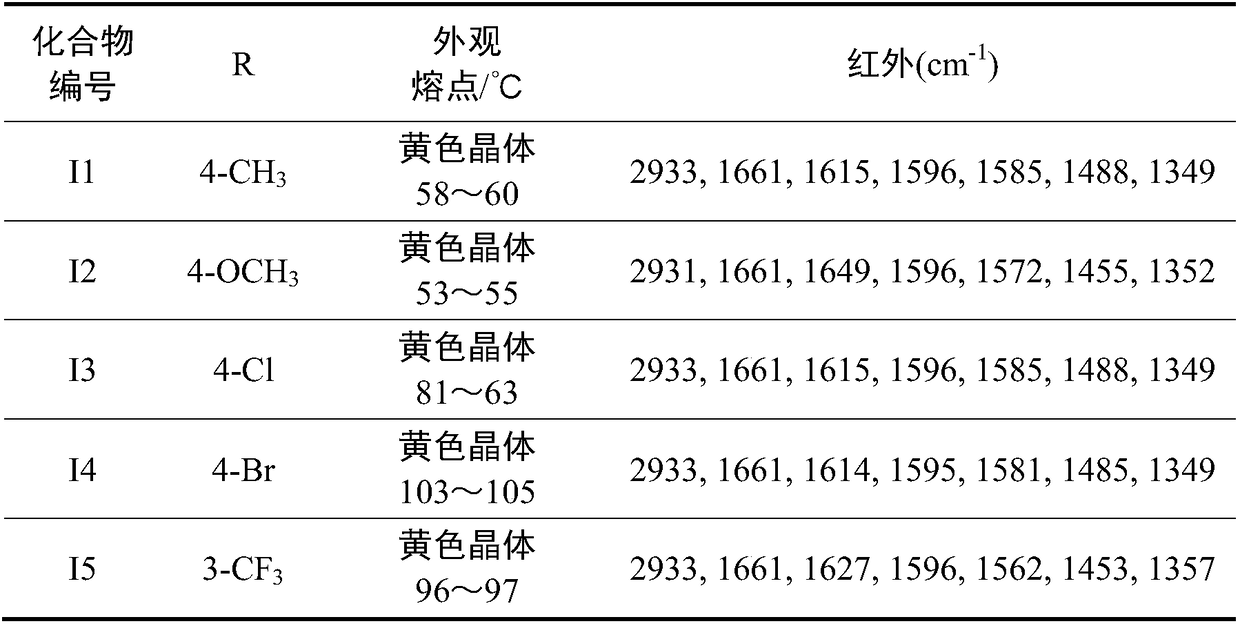

Chalcone compound derived from Beta-ionone and preparation method and application thereof

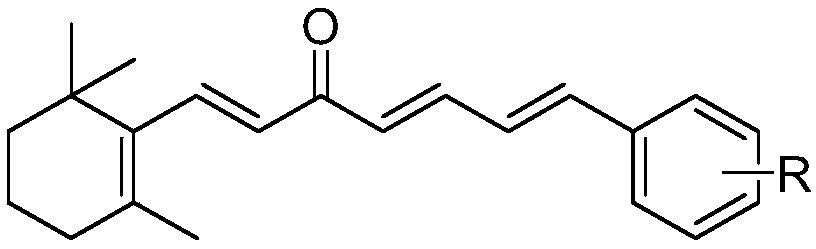

ActiveCN109053406ASimple processEasy to implementBiocideOrganic compound preparationOrganic solventChalcone

The invention relates to a chalcone compound derived from Beta-ionone and a preparation method and an application thereof. The preparation method for the compound specifically comprises the followingsteps: in an organic solvent, and in the presence of a trapping agent, performing a condensation reaction on the Beta-ionone and substituted cinnamyl aldehyde, to obtain the compound. The provided chalcone compound derived from the Beta-ionone has apparent attractive activity of apolygus lucorum and insecticidal activity of plutella xylostella and tetranychus cinnabrinus, and has the direct control effect to the apolygus lucorum, the plutella xylostella and the tetranychus cinnabrinus. In addition, the preparation method is simple in process, easy to implement, less in by-product, higher in yield, and low in cost, and has a practical application value in agricultural production, and extensive application prospect.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

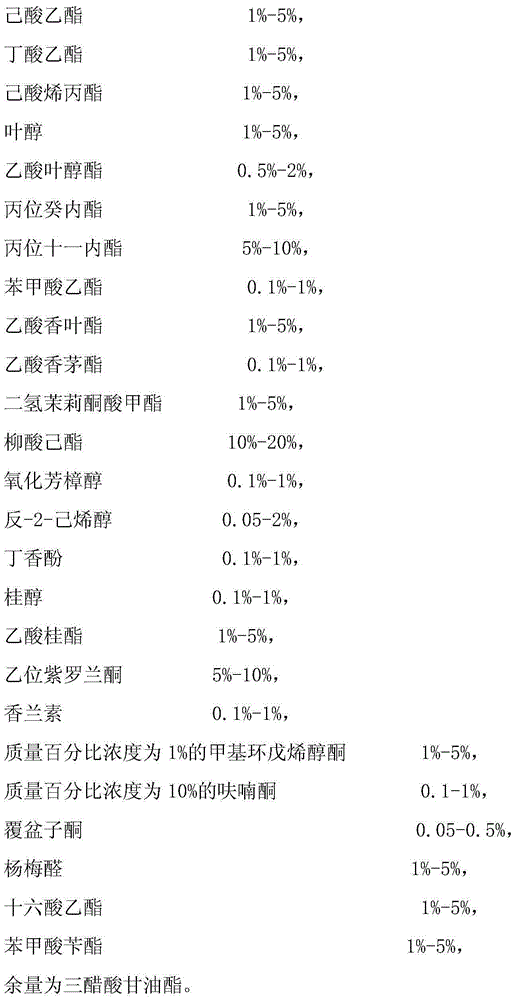

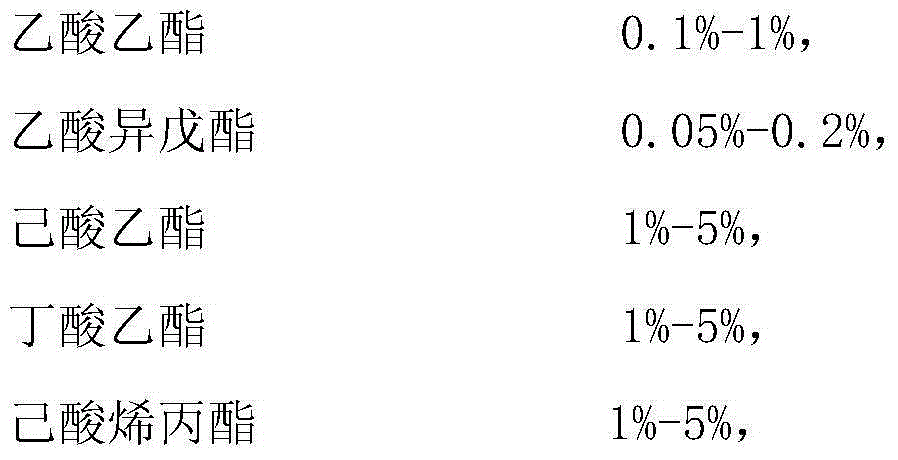

Strawberry essence for oil-based ink and preparation method of strawberry essence

InactiveCN105132175AIncrease added valueEasy to useInksEssential-oils/perfumesSolubilityCinnamyl acetate

The invention relates to strawberry essence for oil-based ink. The strawberry essence consists of strawberry essence, maltodextrin and starch sodium octenylsuccinate, wherein the strawberry essence consists of ethyl acetate, isoamyl acetate, ethyl caproate, ethyl butyrate, allyl hexanoate, leaf alcohol, cis-3-hexenyl acetate, decalactone, peach aldehyde, ethyl benzoate, geranyl acetate, citronellyl acetate, dihydrojasmonic acid methyl ester, hexyl salicylate, linalool oxide, trans-2-hexenol, eugenol, cinnamyl alcohol, cinnamyl acetate, beta-Ionone, vanillin, methyl cyclopentenolone, furanone, raspberry ketone, ethyl methylphenylglycidate, ethyl palmitate, benzyl benzoate and glycerol triacetate. The invention also provides a preparation method of the strawberry essence for the oil-based ink. The strawberry essence, the maltodextrin, the starch sodium octenylsuccinate and water are mixed; homogenizing and emulsification are performed; then, spray drying is carried out; particular strawberry essence is formed, so that the aroma retaining effect and the oil solubility of the essence are improved; the strawberry essence is applicable to perfuming of the oil-based ink.

Owner:SHANGHAI INST OF TECH

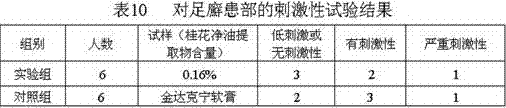

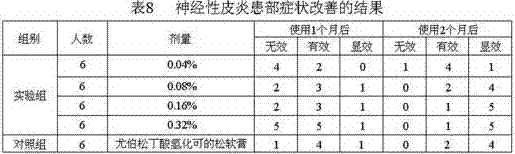

Skin nourishing/treating composition capable of relieving pruritus

ActiveCN107158086AItching ReliefCosmetic preparationsOrganic active ingredientsAdditive ingredientGas chromatography–mass spectrometry

The invention discloses a skin nourishing / treating composition capable of relieving pruritus. According to a preparation method, a sweet osmanthus essential oil form extract product is taken as an active component. The skin nourishing / treating composition comprises, by weight, 0.01 to 0.2% of the sweet osmanthus essential oil form extract product, and the balance an acceptable accessory component in skin external preparations; wherein in the sweet osmanthus essential oil form extract product, the gas chromatography-mass spectrometry total chromatographic ion peak area of marking compositions, including a linalool derivative, a beta-ionone derivative, a gamma-decalactone derivative, an alpha-linolenic acid and a linolenate, in the sweet osmanthus essential oil form extract product at least accounts for 15% of the liquid chromatography total peak area of the sweet osmanthus essential oil form extract product. It is shown by experiments that drugs and / or cosmetic preparations prepared from the skin nourishing / treating composition are capable of relieving pruritus caused by different reasons obviously, and are beneficial for nourishing and treating of infected skin.

Owner:成都华西珐玛生物科技有限公司

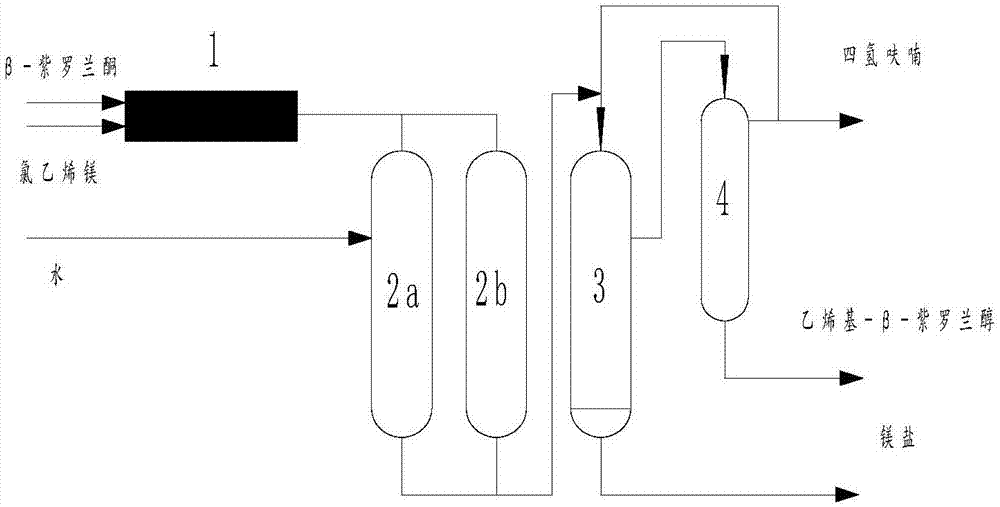

Method for continuously producing vinyl-beta-ionol

PendingCN108002981AReduce generationReduce runawayOrganic compound preparationMagnesium chloridesChlorideStatic mixer

The invention provides a method for continuously producing vinyl-beta-ionol, which comprises the following steps: taking beta-ionone as a raw material, enabling the beta-ionone and a vinyl-magnesium chloride solution to enter a static mixer, and reacting to generate an intermediate; reacting the intermediate and water in a quenching reactor to generate vinyl-beat-ionol and basic magnesium chloride; centrifugally filtering to obtain a vinyl-beta-ionol solution, rectifying the vinyl-beta-ionol solution to obtain vinyl-beta-ionol. The method provided by the invention has the advantages that: (1)continuous production of vinyl-beta-ionol is realized; (2) safety in a Grignard reaction and a quenching process is improved; (3) the production technology flow is simplified, the production period isshortened, and the production cost is reduced.

Owner:WANHUA CHEM GRP CO LTD

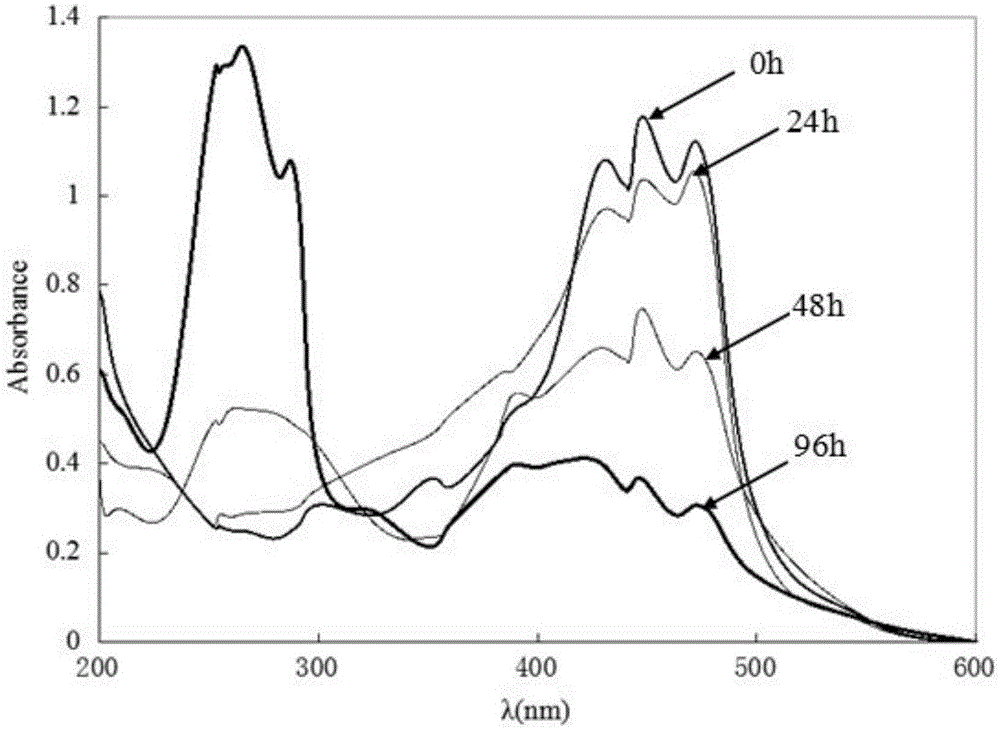

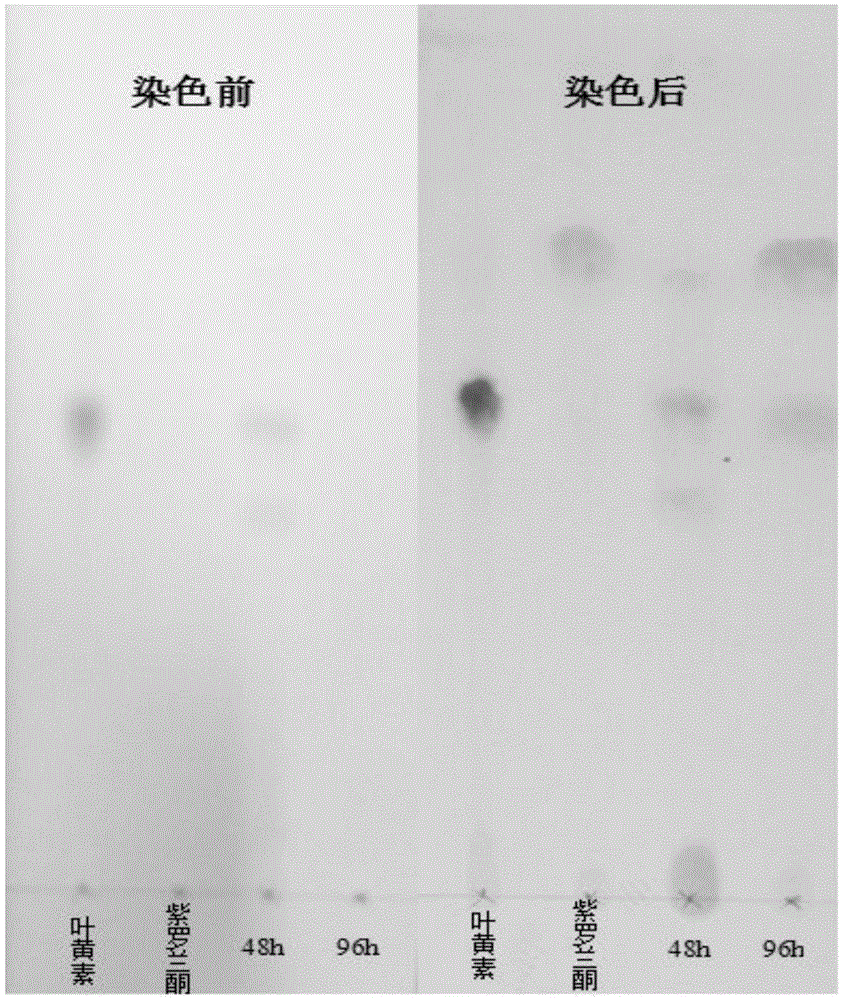

Microbial-conversion-based method for synthesizing 3-hydroxy beta-ionone and beta-ionone

InactiveCN105154479AImprove qualityMicroorganism based processesFermentationLuteinMicrobial transformation

The invention discloses a microbial-conversion-based method for synthesizing 3-hydroxy beta-ionone and beta-ionone. The method includes the following steps: (1), culturing scattered pantoea, inoculating a triangular bottle filled with a seed culture medium with a scattered pantoea strain, and oscillating at 180-200r / min under the conditions of pH being 6.5 and temperature being 30-34 DEG C for culture for 10-18h to obtain seed liquid; (2), fermenting in a seed tank; (3), obtaining 3-hydroxy beta-ionone and beta-ionone. By searching fermentation culture media, an optimal fermentation culture medium capable of efficiently degrading lutein is obtained, and 3-hydroxy beta-ionone and beta-ionone which have aromatic substances can be generated. The 3-hydroxy beta-ionone and beta-ionone are important aromatic substances, and tobacco quality can be improved greatly by adding a small amount of the aromatic substances into tobacco. The microbial-conversion-based method has huge application prospect in utilizing biologically-degraded lutein and generating natural aromatic substances.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

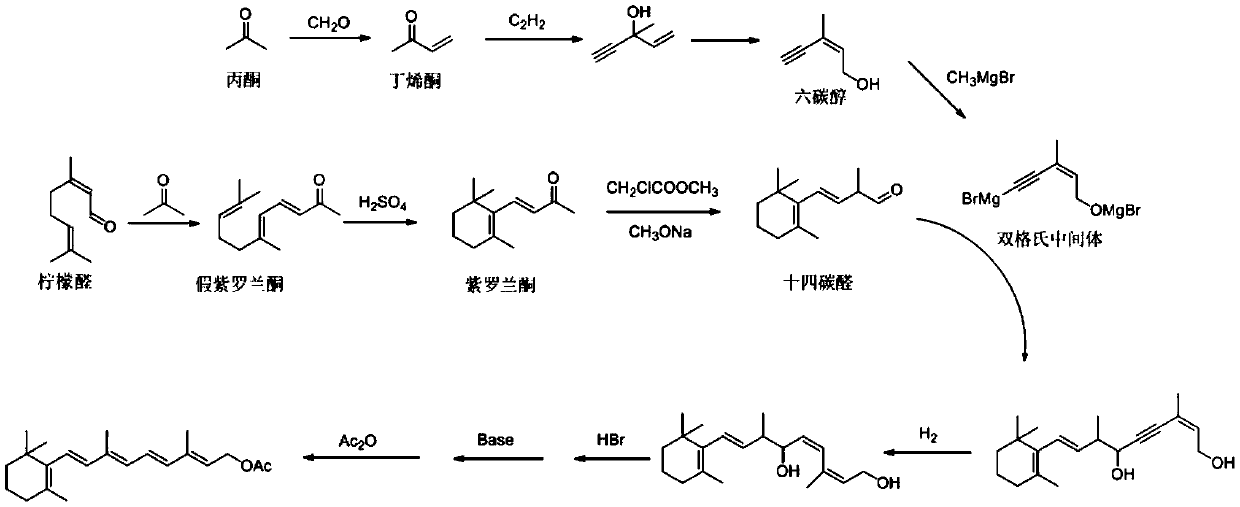

Synthetic method for vitamin A intermediate C14 aldehyde

InactiveCN105254479AHigh yieldHigh purityMagnesium organic compoundsCarbonyl compound preparation by hydrolysisAcid catalysisGrignard reagent

The invention relates to a synthetic method for vitamin A intermediate C14 aldehyde. The synthetic method includes the following steps that 1, cyclocitral is used as a raw material and condensed with a chloro-isocrotyl methyl ether Grignard reagent to prepare a C14 alkenyl ether hydroxyl product; 2, the hydroxy group is hydrolyzed into olefin and alkenyl ether at the same time under acid catalysis to obtain C14 aldehyde. The path of the synthetic method is concise, a beta-ionone intermediate is unnecessary, C14 aldehyde is obtained by directly condensing the cyclocitral, and the yield and the purity of C14 aldehyde are high. The product is obtained in an acid system and prevented from deteriorating in a high-temperature strong base environment; the condensation compound of the chloro-isocrotyl methyl ether Grignard reagent is hydrolyzed into olefin and alkenyl ether to obtain aldehyde through hydrolysis in one step.

Owner:SHANGYU NHU BIOCHEM IND

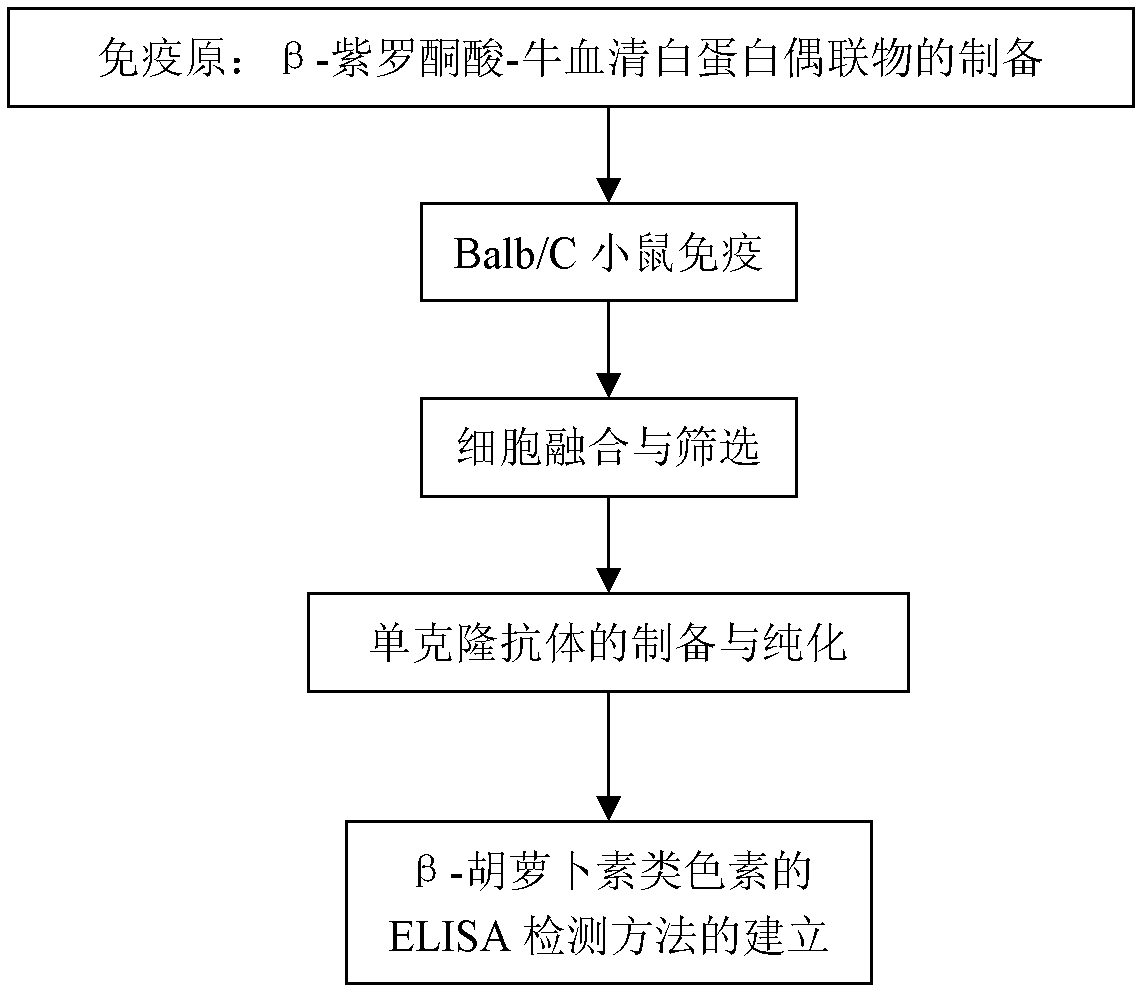

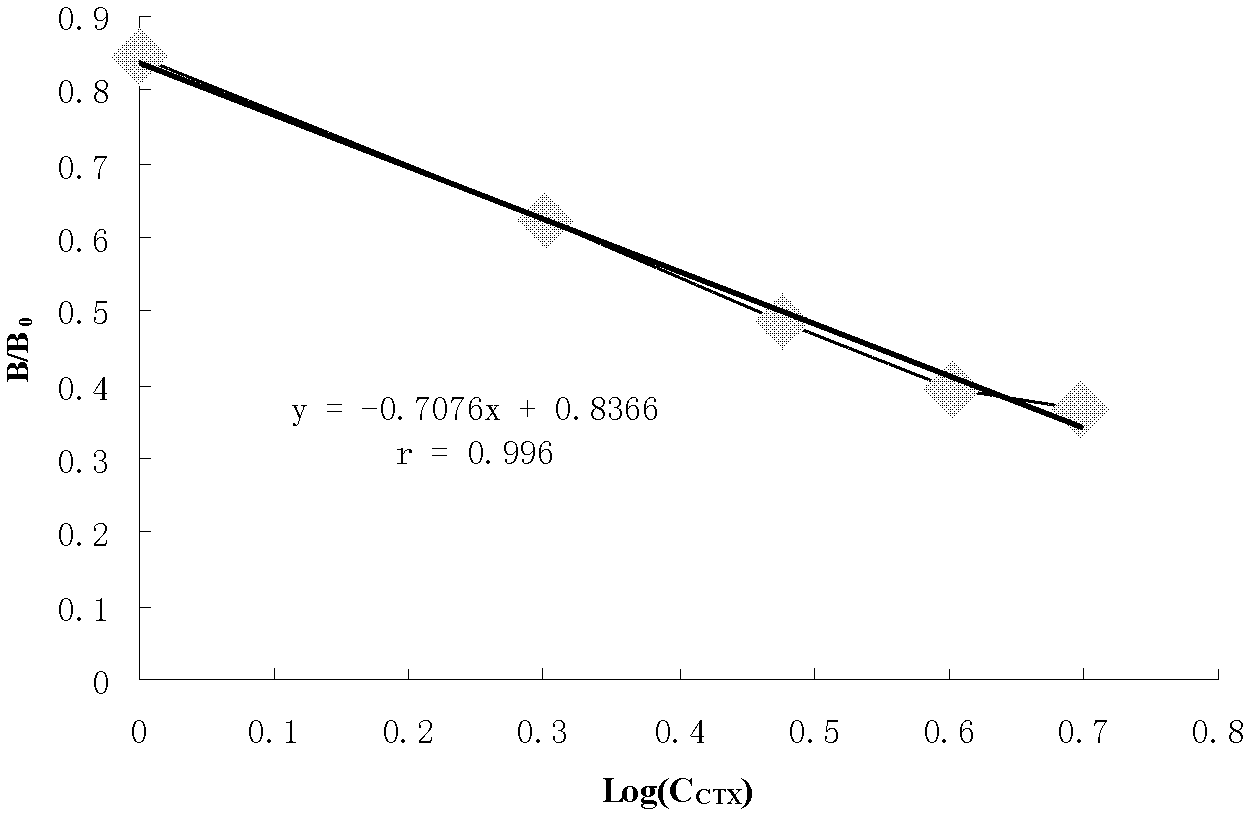

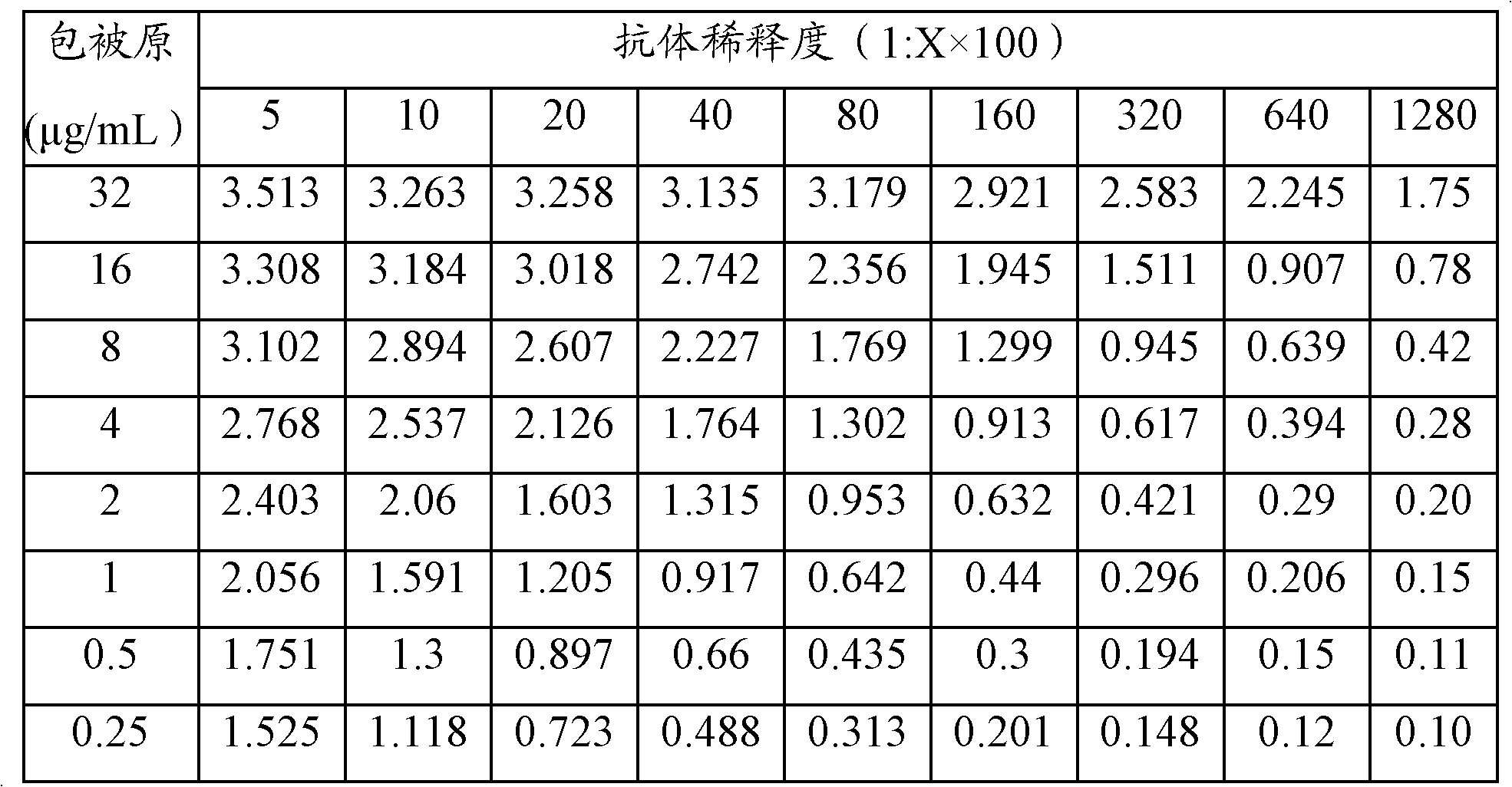

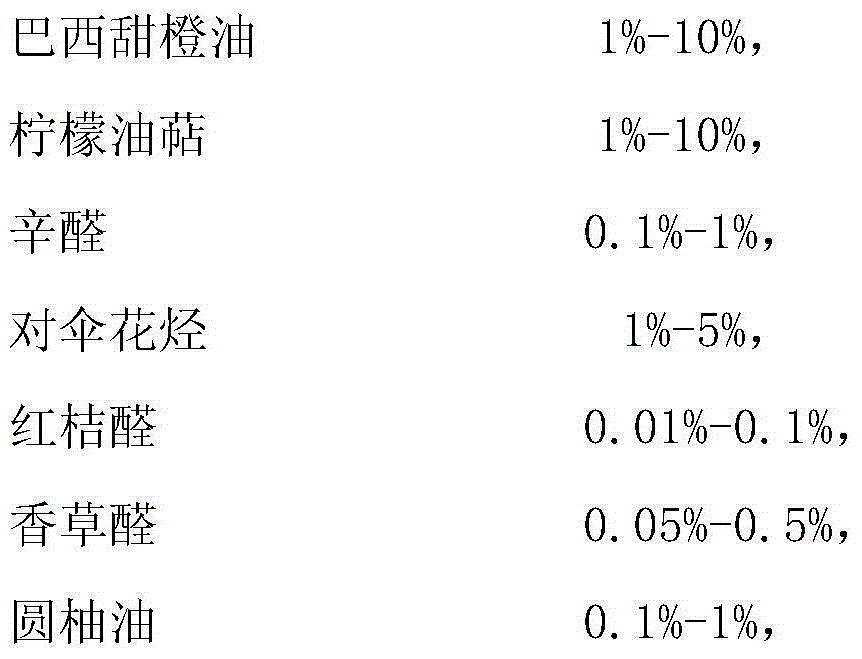

Monoclonal antibody, enzyme-linked immunosorbent assay (ELISA) method and kit for detecting beta-carotene pigments

InactiveCN102585007AStrong specificityHigh sensitivityMicroorganism based processesTissue cultureBeta-CaroteneElisa method

The invention discloses a specific monoclonal antibody capable of identifying beta-carotene pigments and an enzyme-linked immunosorbent assay (ELISA) method and kit for detecting beta-carotene pigments. The monoclonal antibody is secreted by a hybridoma cell DCC / C11 and the hybridoma cell is collected in the China Center for Type Culture Collection, with collection number being CCTCC NO:C201146. The ELISA method comprises the steps of preparation of immunogen, coating antigen and the antibody, treatment and detection of samples, and the like. The ELISA method and the kit can detect the total content of canthaxanthin, beta-carotene, beta-apo-8'-carotenal, xanthophyll, capsorubin and beta-ionone in the samples by one step, thus shortening the detection time and lowering the detection cost; and the ELISA method and the kit have the characteristics of high detection sensitivity, good precision and good accuracy.

Owner:HUAZHONG AGRI UNIV

Milk flavor-tea flavor combined essence for recombinant tobacco leaf wrapping and preparation method thereof

InactiveCN106916626AFresh and natural aromaProminent and long-lasting scentNon-fibrous pulp additionPaper coatingAdditive ingredientDamascone

The invention belongs to the technical field of cigarette flavor and essence and particularly relates to milk flavor-tea flavor combined essence for recombinant tobacco leaf wrapping and a preparation method thereof. The milk flavor-tea flavor combined essence comprises, by mass, 0.001 to 0.005 parts of cis-3-hexenyl acetate, 0.08 to 0.4 parts of linalool, 0.05 to 0.25 parts of linalool oxide and 2 to 7 parts of geraniol. The milk flavor-tea flavor combined essence has compound milk flavor and tea flavor, is suitable for the field of manufacture of cigarettes and is particularly suitable for being used in recombinant tobacco leaf wrapping. In all flavor ingredients, cis-3-hexenyl acetate, linalool, linalool oxide, geraniol, geranyl acetate, linalyl acetate, beta-ionone, beta-damascone, ethyl acetate and ethyl butyrate can produce a milk flavor. The milk flavor-tea flavor combined essence has layering of a milk flavor and a tea flavor, realizes flavor smooth transition, is conducive to improvement of a cigarette flavor and improves cigarette flavor harmony.

Owner:WUHAN HUANGHELOU FLAVOR & SPICES

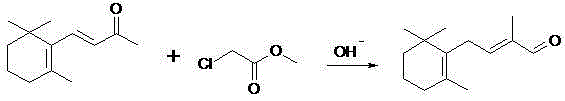

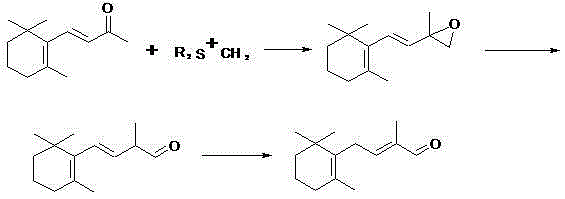

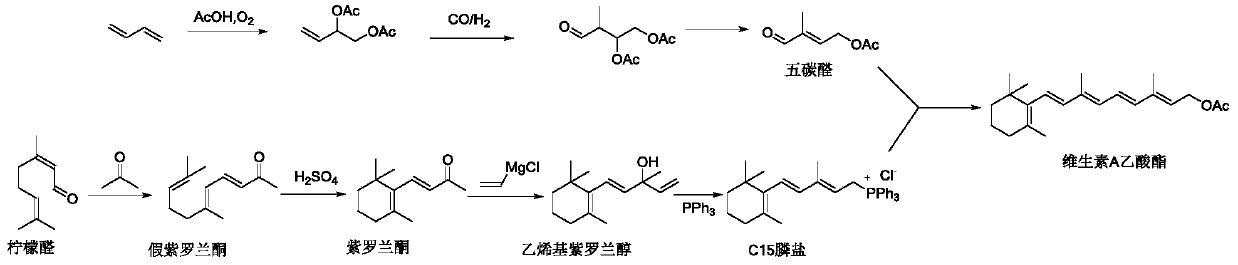

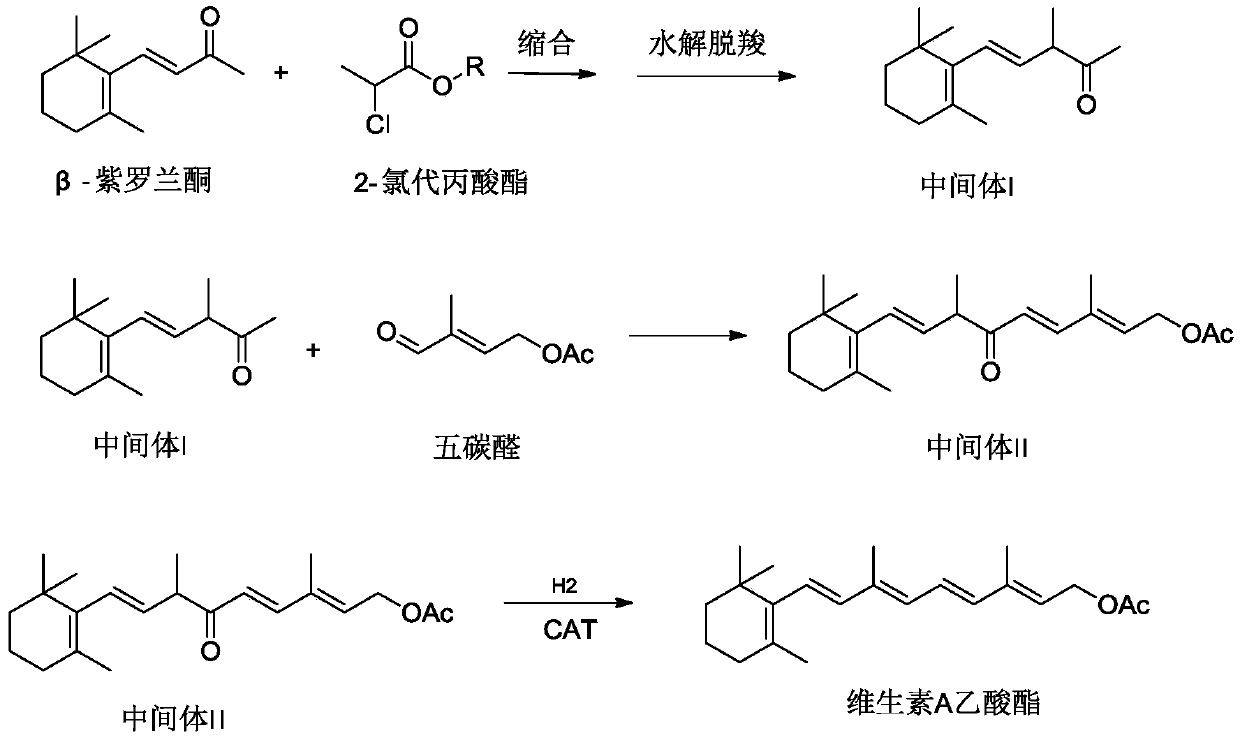

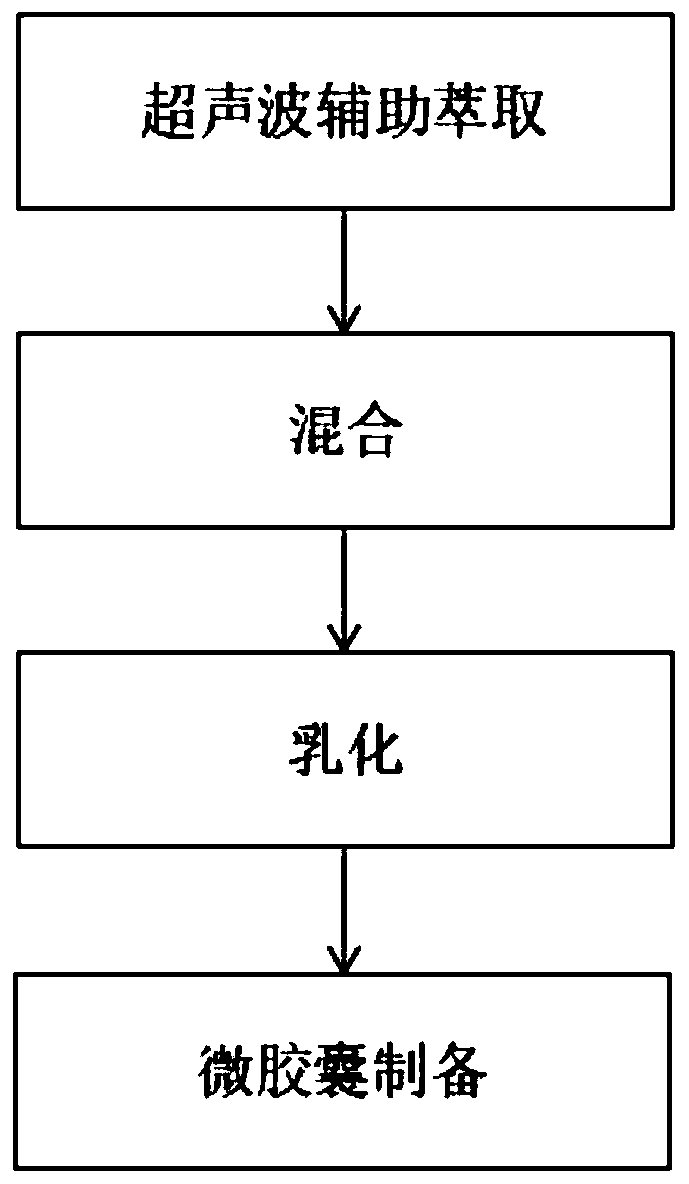

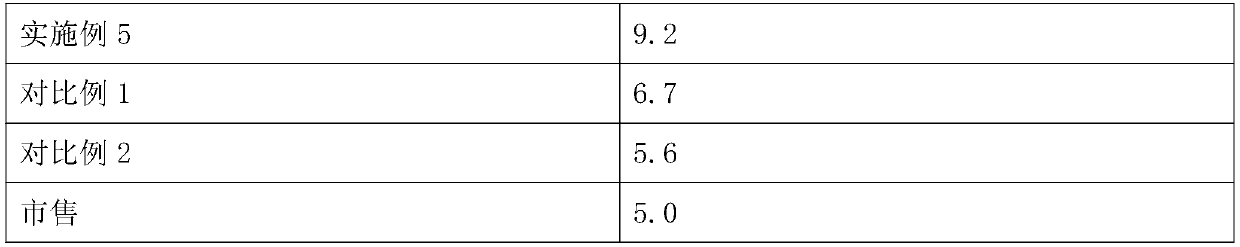

Preparation method of retinyl acetate

ActiveCN110143874AMild reaction conditionsEasy to realize industrial productionOrganic compound preparationCarboxylic acid esters preparationRetinyl acetateHydrogenation reaction

The invention provides a preparation method of retinyl acetate. The method comprises the following steps: performing a condensation reaction on beta-ionone and 2-chloropropionate under the action of astrong alkali, and performing hydrolysis decarboxylation to form an intermediate I; performing a condensation reaction on the intermediate I and pentaaldehyde to produce an intermediate II; and performing a hydrogenation reaction on the intermediate II under the action of a catalyst, and performing a dehydration reaction to obtain the retinyl acetate. The method provided by the invention avoids the disadvantages of a current process and has an economical and effective process route.

Owner:WANHUA CHEM GRP CO LTD

Mango essence, and preparation method thereof

InactiveCN110331042AReduce manufacturing costHuge sales marketSugar food ingredientsEssential-oils/perfumesFood additiveBeta-selinene

The invention provides a mango essence. The mango essence comprises following raw materials: a mango extract, geraniol, lactic acid, sweet orange oil, linalool, alpha-selinene, beta-selinene, methyl butyrate, (E)-2-hexenoic acid-(Z)-3-hexenyl ester, 1-methylbutyrolactone, (Z)-carveol, p-cymene-8-ol, globulol, (E, Z) 2,6- nonadienal, acetophenone, butyl dione, beta-ionone, lemon oil, clove oil, nutmeg oil and ethanol. The fragrance of the mango essence is soft, mellow and thick, stable in properties, and natural, so that consumers are provided with fragrance feel close to that of fresh mangoes,user approval degree is high, the mango essence can be added into food and beverage as a food additive, obtained products are provided with the fragrance and mouthfeel of fresh mangoes, and are welcomed by consumers.

Owner:宁波蒙曼生物科技有限公司

Lemon essence used in oil-based ink and preparation method of lemon essence

InactiveCN105176684AImprove fragranceGood oil solubilityInksEssential-oils/perfumesSolubilityLimonium

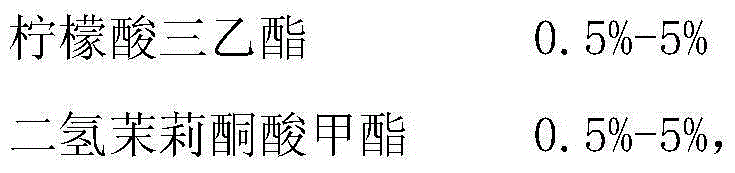

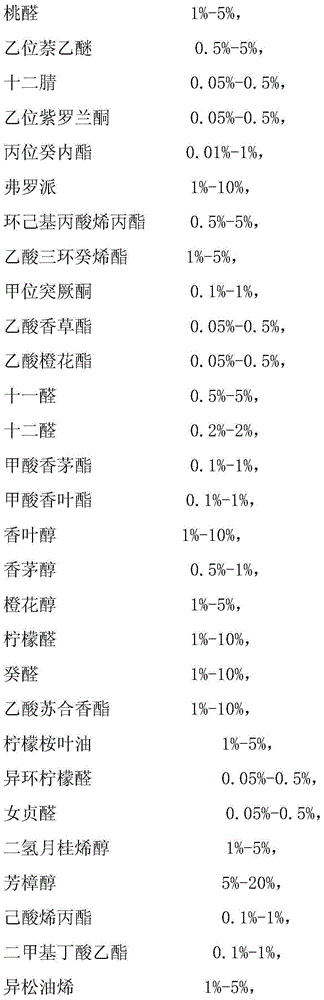

The invention provides lemon essence used in oil-based ink. The lemon essence is prepared from a lemon essence body, maltodextrin and starch sodium octenylsuccinate, wherein the lemon essence body is prepared from triethyl citrate, methyl dihydrojasmonate, peach aldehyde, beta-naphthol ethyl ether, dodecanenitrile, beta-ionone, gamma-decalactone,floropai, allyl cyclohexanepropionate, verdyl acetate, damacscone alpha, vanillin acetate, neryl acetate, undecanal, lauraldehyde, citronellyl formate, geranyl formate, geraniol, citronellol, nerol, citral, capraldehyde, styralyl acetate, citriodora oil, isocyclocitral, triplal, dihydromyrcenol, linalool, allyl hexanoate, ethyl-2-methylbutyrate, terpinolene, Brazil orange oil, lemon oil terpene, octyl aldehyde, paracymene, tangerine aldehyde, vanillic aldehyde, grapefruit oil and glyceryl triacetate. The invention further provides a preparation method of the lemon essence used in the oil-based ink. By means of the lemon essence used in the oil-based ink and the preparation method of the lemon essence, the fragrance retention effect and oil solubility of the essence are improved.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

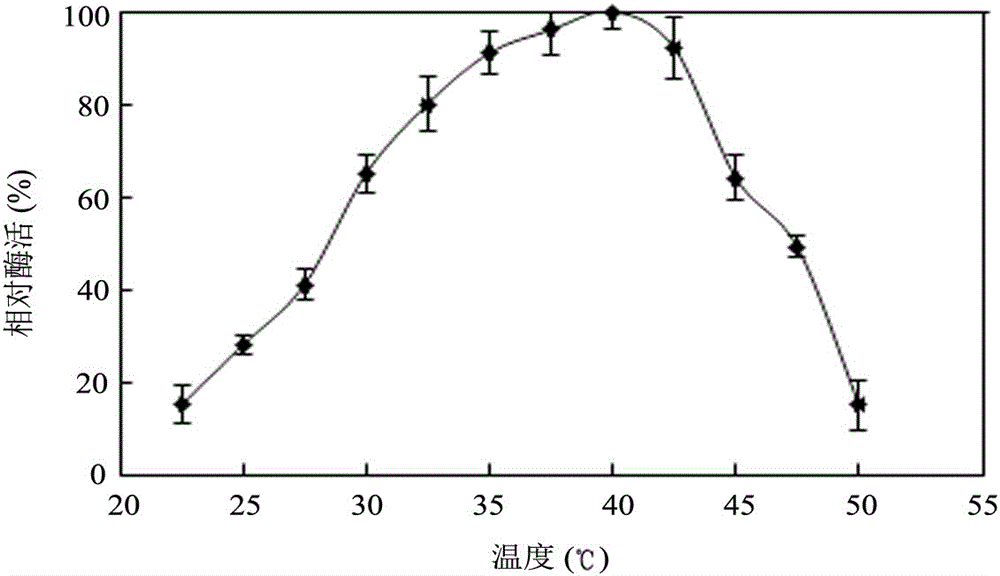

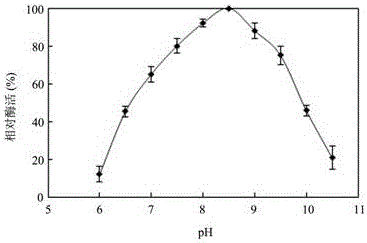

Preparation method and application of carotenoid 9,10' dioxygenase

ActiveCN106282137AHigh catalytic specificityShort reaction timeOxidoreductasesFermentationCarotenoidAmino acid

The invention belongs to the field of bioengineering and relates to a preparation method and application of a carotenoid 9,10' dioxygenase. The preparation method comprises the following steps: cultivating enterobacter hormaechei, and extracting a whole genome sequence; constructing a recombinant plasmid of a carotenoid 9,10' dioxygenase gene; inducing expression of the carotenoid 9,10'dioxygenase gene, and purifying zymoprotein; and analyzing and identifying enzymatic properties of the carotenoid 9,10' dioxygenase. The prepared carotenoid 9,10' dioxygenase gene can efficiently catalyze and synthesize beta-ionone, catalysis specificity is high, reaction products are few, and reaction time is short; a novel enzyme resource different from discovered carotenoid 9,10' dioxygenase is obtained; the carotenoid 9,10' dioxygenase has different amino acid sequences and enzymatic characteristics; and reaction conditions are optimized, and yield of the beta-ionone reaches 79.4%.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

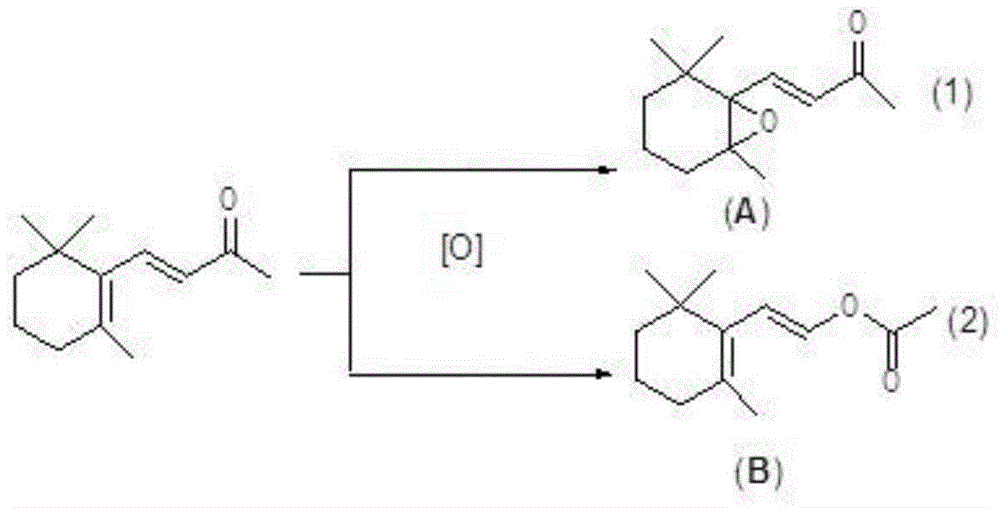

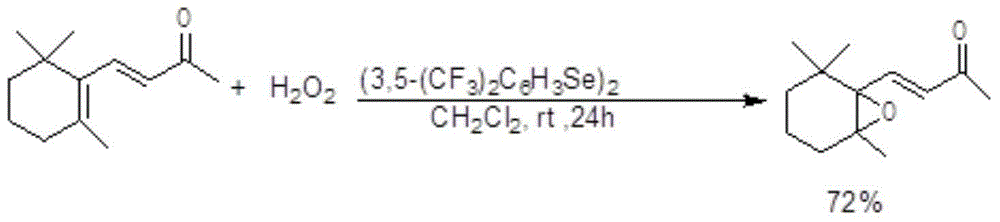

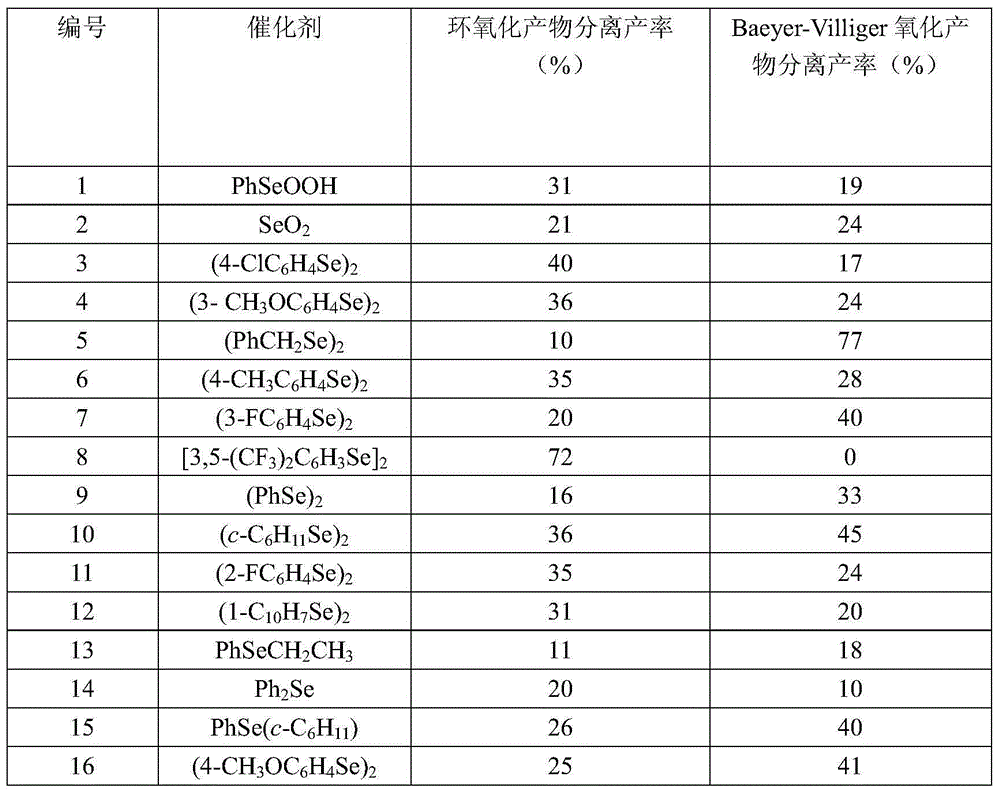

Production method of beta-ionone epoxide

InactiveCN104557792AImprove economyLess corrosiveOrganic chemistryChemical recyclingFood flavorNitrogen gas

The invention discloses a production method of beta-ionone epoxide in the field of flavor production, which comprises the following steps: in a nitrogen protective atmosphere, oxidizing beta-ionone in a solvent by using di(3,5-ditrifluoromethylphenyl)diselenide as a catalyst and hydrogen peroxide as an oxidizer while controlling the temperature of the reaction system at 0-40 DEG C to obtain the epoxidation product 4-[2,2,6-trimethyl-7-oxabicyclo[4.1.0]heptyl-1-yl]-3-butenyl-2-one. The method can synthesize the 4-[2,2,6-trimethyl-7-oxabicyclo[4.1.0]heptyl-1-yl]-3-butenyl-2-one at high selectivity. The oxidizer is clean, has high economical efficiency, and is harmless to the environment since the reduction byproduct of the oxidizer is only water. The method does not use any metal catalyst, and the used organic selenium catalyst is ecologically friendly. The reaction is performed under mild conditions in a neutral environment, and has small corrosivity for equipment, so the equipment is durable; and the catalyst is recoverable, and thus, is more suitable for industrial production.

Owner:YANGZHOU UNIV

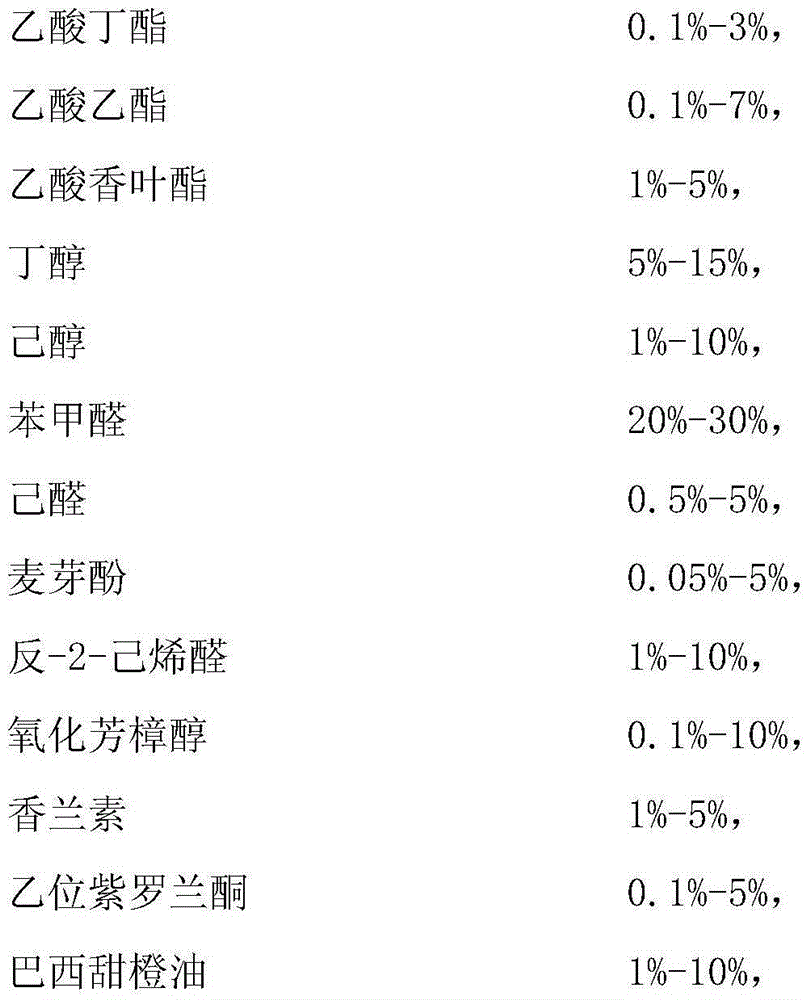

Cherry flavoring essence for oily printing ink and preparation method therefor

InactiveCN105087164AImprove fragranceGood oil solubilityInksEssential-oils/perfumesSolubilityBenzaldehyde

The invention relates to cherry flavoring essence for oily printing ink. The cherry flavoring essence is prepared from the raw materials in percentage by weight: 5 to 20 percent of cherry essence, 50 to 80 percent of maltodextrin and 5 to 30 percent of starch sodium octenylsuccinate, wherein the cherry essence is prepared from butyl acetate, ethyl acetate, geranyl acetate, butanol, hexanol, benzaldehyde, hexanal, maltol, trans-2-hexenoic aldehyde, linalool oxide, vanillin, beta-ionone, orange oil Brasil and glyceryl triacetate. The invention also provides a preparation method for the cherry flavoring essence for the oily printing ink. According to the preparation method, the granular cherry flavoring essence is prepared through uniformly mixing the cherry essence with maltodextrin, starch sodium octenylsuccinate and deionized water, carrying out homogenizing emulsification, and then, carrying out spray drying, thus, the perfume retaining effect and oil solubility of the flavoring essence are improved, and the flavoring essence can be applicable to the perfuming of the oily printing ink. The cherry flavoring essence for the oily printing ink, prepared by the preparation method, is rich and vivid in perfume, high in natural feeling and lasting in perfume retaining.

Owner:SHANGHAI INST OF TECH

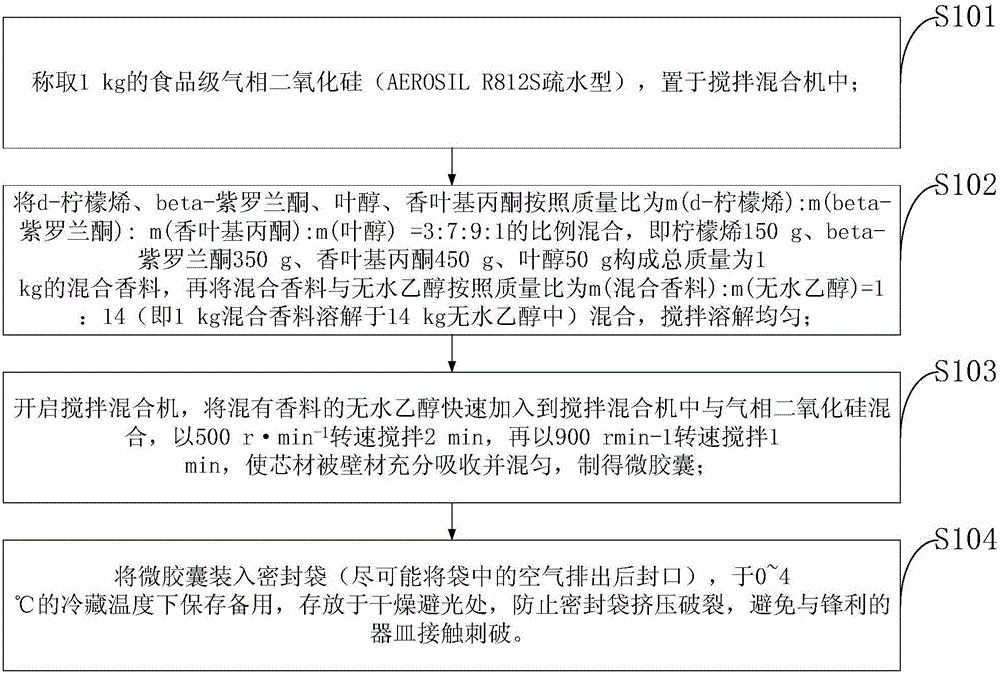

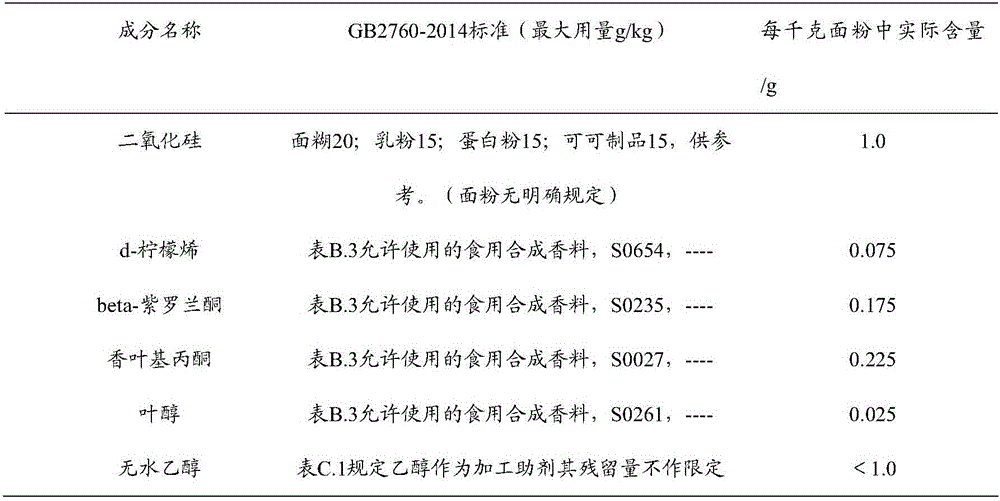

Microcapsules embedding food flavoring to avoid tribolium castaneum and preparation method of microcapsules

InactiveCN106148005ANo significant effect on qualityQuality impactEssential-oils/perfumesFood flavoringsEmbedding rate

The invention discloses microcapsules embedding food flavoring to avoid tribolium castaneum and a preparation method of the microcapsules. By adopting fumed silica as the wall material of the microcapsules, the embedding rate and the slow release property are better, and the lasting time of insecticidal effect is greatly prolonged; and the preparation method comprises the following steps: weighing the fumed silica and putting into a stirring uniform mixer; dissolving d-limonene, beta-ionone, leaf alcohol and geranylacetone in absolute ethyl alcohol; starting a stirrer and quickly adding the absolute ethyl alcohol mixed with flavoring into the stirrer for mixing with the fumed silica; stirring for 2min at a speed of 500rpm; then stirring for 1min at a speed of 900rpm so that the core material is sufficiently absorbed by the wall material and uniformly mixed; drying in a drying oven at 50 DEG C and then grinding to obtain microcapsule powder; sealing and storing the microcapsules in a bag with bad air permeability; and storing at low temperature for later use. According to the invention, the preparation technology is simpler, the insecticidal effect is good, the embedding effect and the slow release property are relatively good, the product cost is low, and the product is green and environment-friendly.

Owner:SOUTHWEST UNIVERSITY

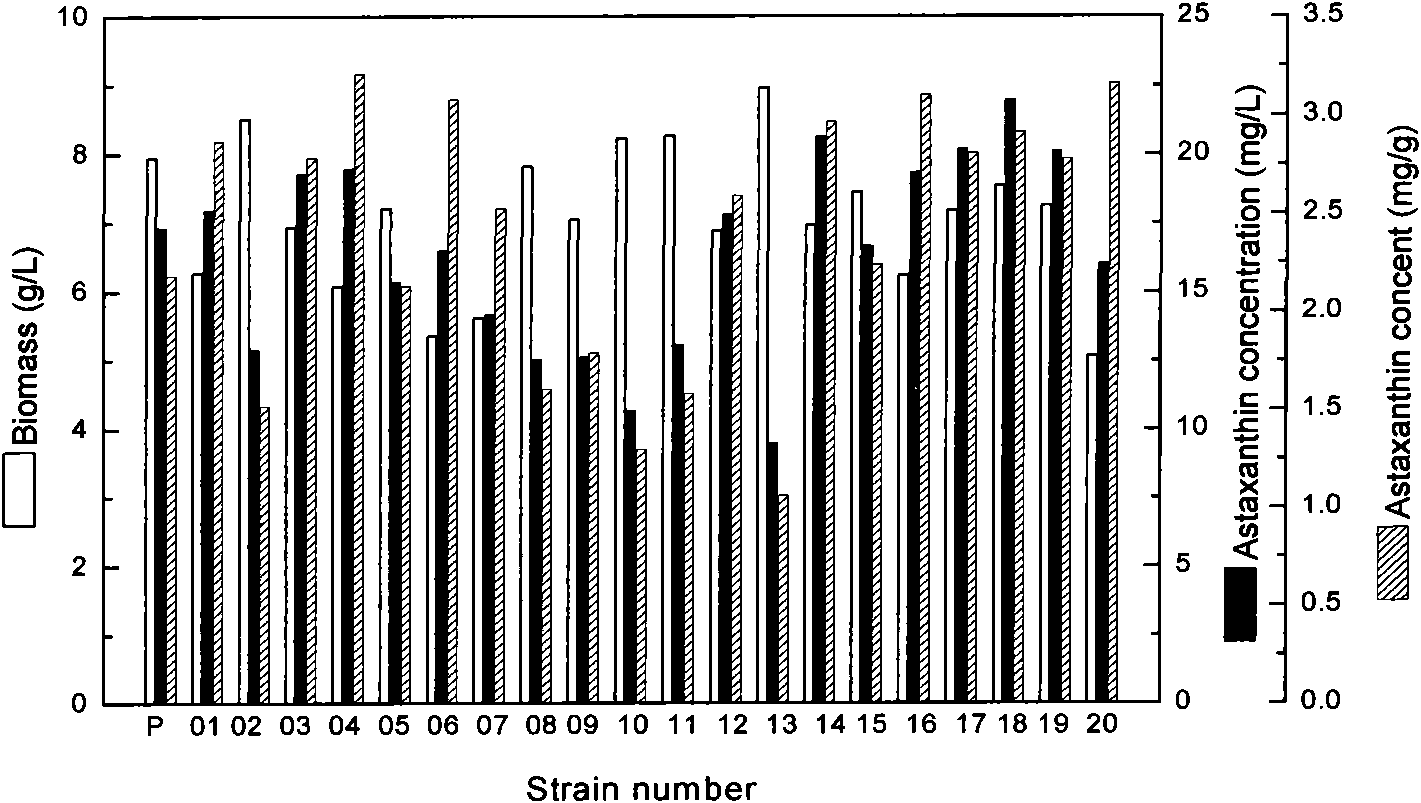

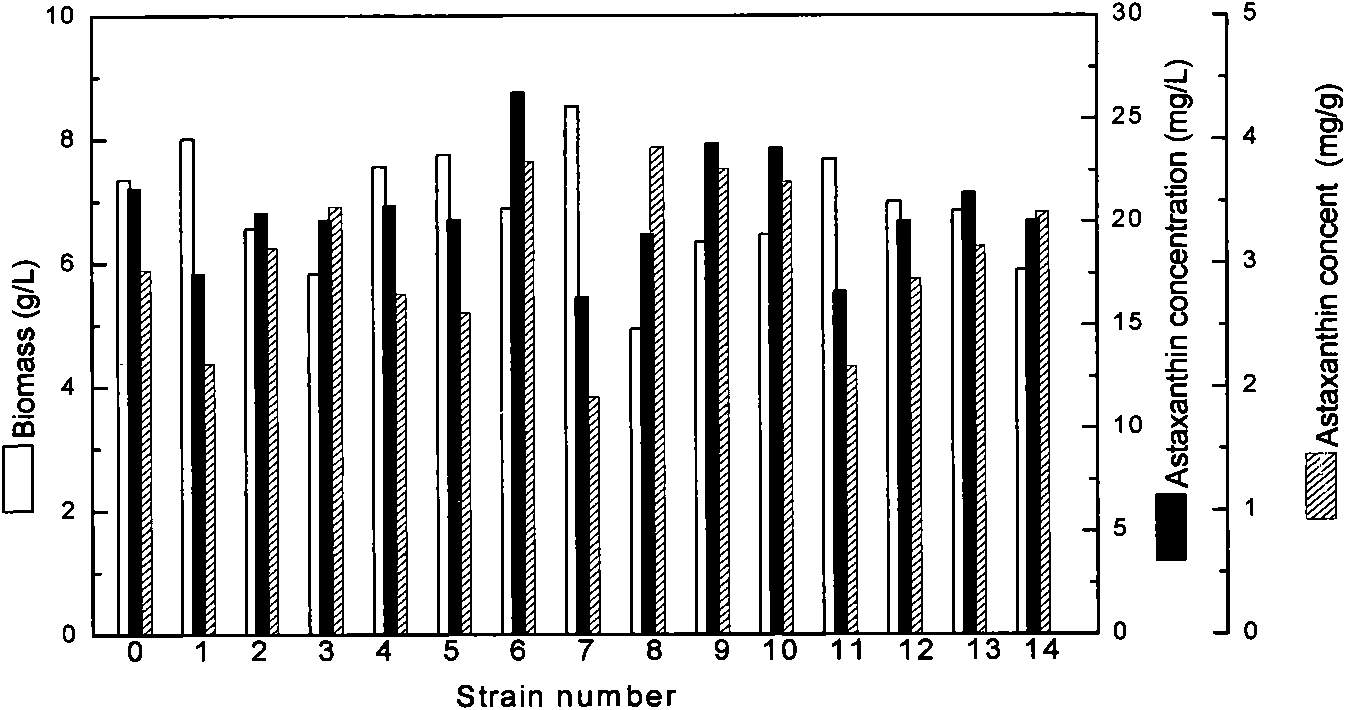

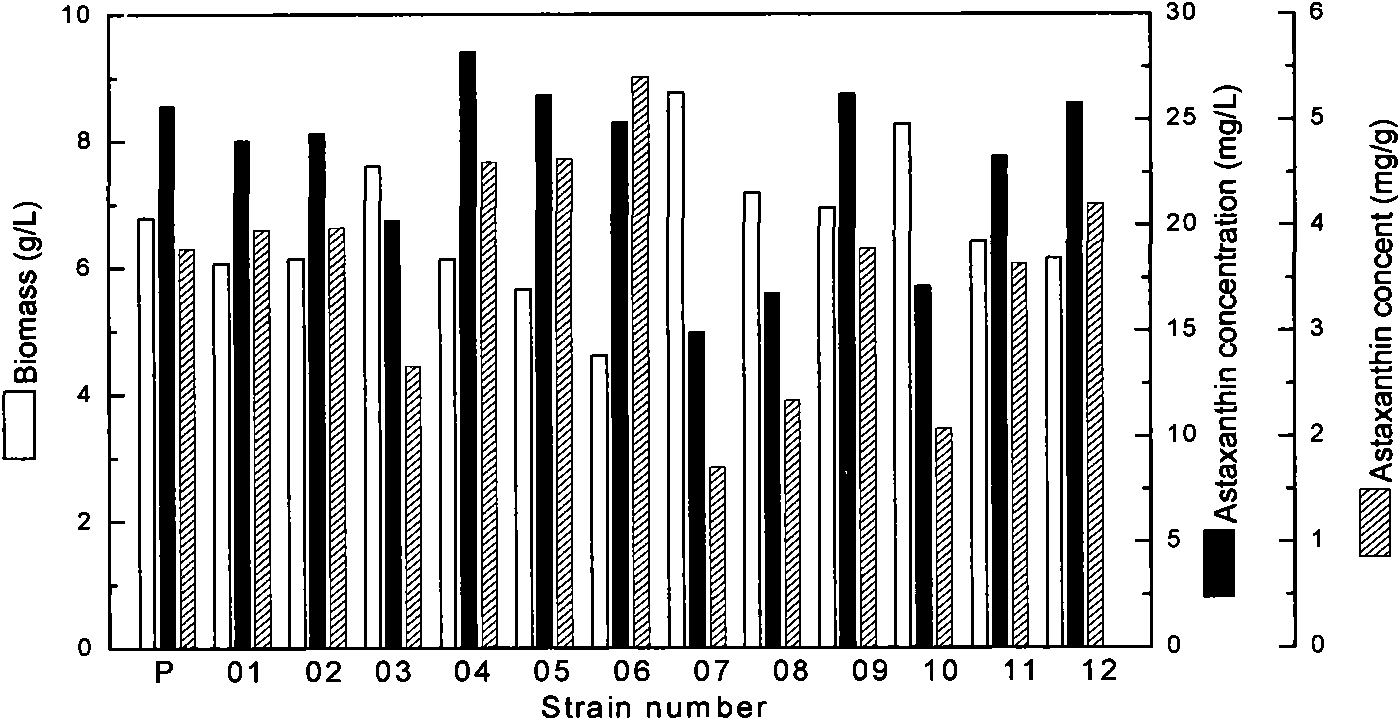

Astaxanthin-producing strain, mutagenesis and screening method and application thereof

ActiveCN101838614BStable outputMeet the requirements of industrial productionFungiMutant preparationMicroorganismYeast

The invention discloses an astaxanthin-producing strain, a mutagenesis and screening method and application thereof, and relates to a microbiological strain and an obtaining method thereof. The astaxanthin-producing strain is a mutagenic strain N1806-04 of phaffia rhodozyma. The method comprises the following steps of: preparing phaffia rhodozyma protoplast by an enzyme method by taking the phaffia rhodozyma as an original strain; and selectively breeding the astaxanthin-producing strain by an NTG mutagenesis method, a beta-ionone screening method and the like to obtain the astaxanthin-producing strain, wherein the yield of the astaxanthin is stable after five times of transfer of culture. By performing scale-up culturing on the astaxanthin-producing strain in a fermentation tank, the yield and the content of the astaxanthin can reach 500 to 600mg / L and 5,000 to 6,300mg / kg (dry weight of cell) respectively and the biomass can reach 80 to 110g / L. The yield and the content of the astaxanthin and the corresponding biomass all meet the requirement of industrial production and have a great application prospect.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com