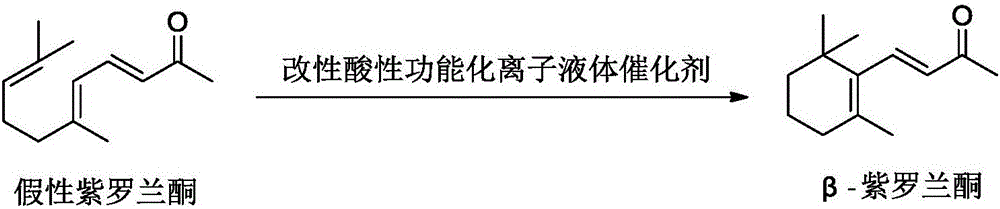

Method for preparing beta-ionone from modified acidic functionalized ionic liquid

A pseudo-ionone, ionic liquid technology, applied in the preparation of carbon-based compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of weak catalyst acidity, low yield, weak acidity of acidic ionic liquids, etc. Achieve the effect of acid enhancement and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

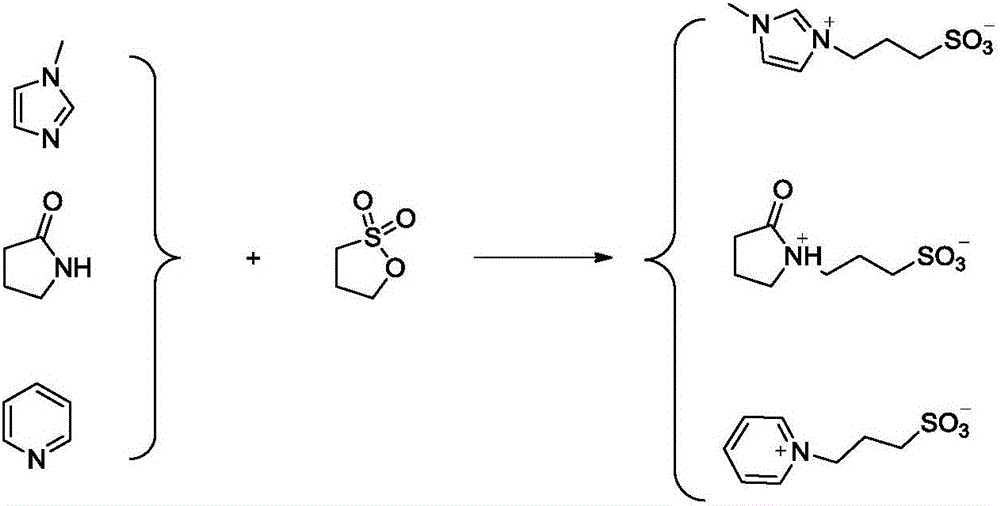

[0035] Preparation of modified acidic functional ionic liquids [C 3 SO 3 HPy]HSO 4 0.2MgCl 2

[0036] 1. Under rapid stirring, dissolve (124.6g, 1.0mol) l,3-propane sultone in 500mL toluene, and after it is completely dissolved, put the system in an ice-water bath; slowly drop (79.1g, 1.0mol) pyridine, after the reaction system was reacted in an ice bath for 2h, it was transferred to another 2h at room temperature;

[0037]2. After the reaction, the resulting white solid was filtered under reduced pressure and washed three times with anhydrous ether; the solid was put into a vacuum drying oven and dried under vacuum at 80°C for 24 hours. get C 3 SO 3 -py-solid;

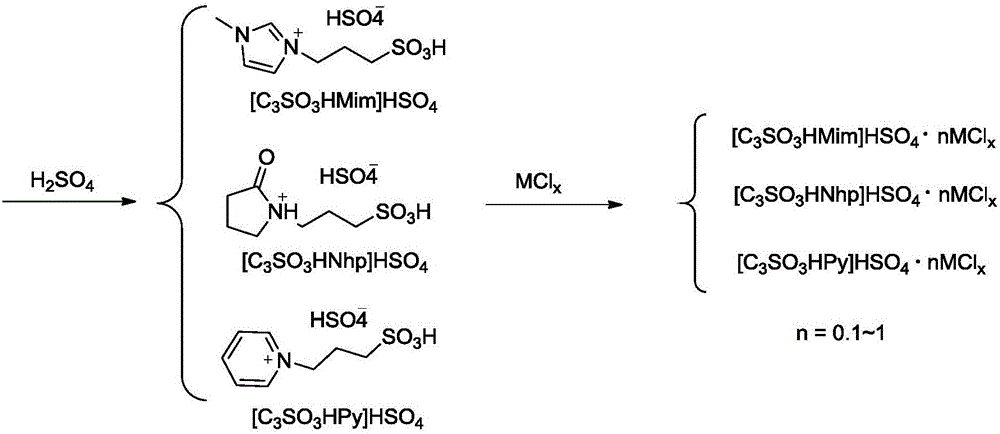

[0038] 3. Put C 3 SO 3 -Py solid (204.2g, 1.0mol) was dissolved in 500ml distilled water and slowly added (100.1g, 1.0mol) 98% concentrated sulfuric acid dropwise at room temperature, then the system was heated to 60°C for 2h;

[0039] 4. After the reaction was completed, (18.9 g, 0.2 mol) magnesium chloride...

Embodiment 2-7

[0041] Change the feeding ratio and synthesize modified acidic functional ionic liquid catalysts 2-7 in a similar way: [C 3 SO 3 HNhp]HSO 4 0.4BaCl 2 , [C 3 SO 3 HMim] HSO 4 0.3NdCl 3 , [C 3 SO 3 HNhp]HSO 4 0.1 LaCl 3 , [C 3 SO 3 HPy]HSO 4 ·ScCl 3 , [C 3 SO 3 HMim] HSO 4 0.2GdCl 3 and [C 3 SO 3 HMim] HSO 4 0.4LuCl 3 , the reaction conditions are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com