Method for preparing beta-ionone by using pseudoionone as raw materials

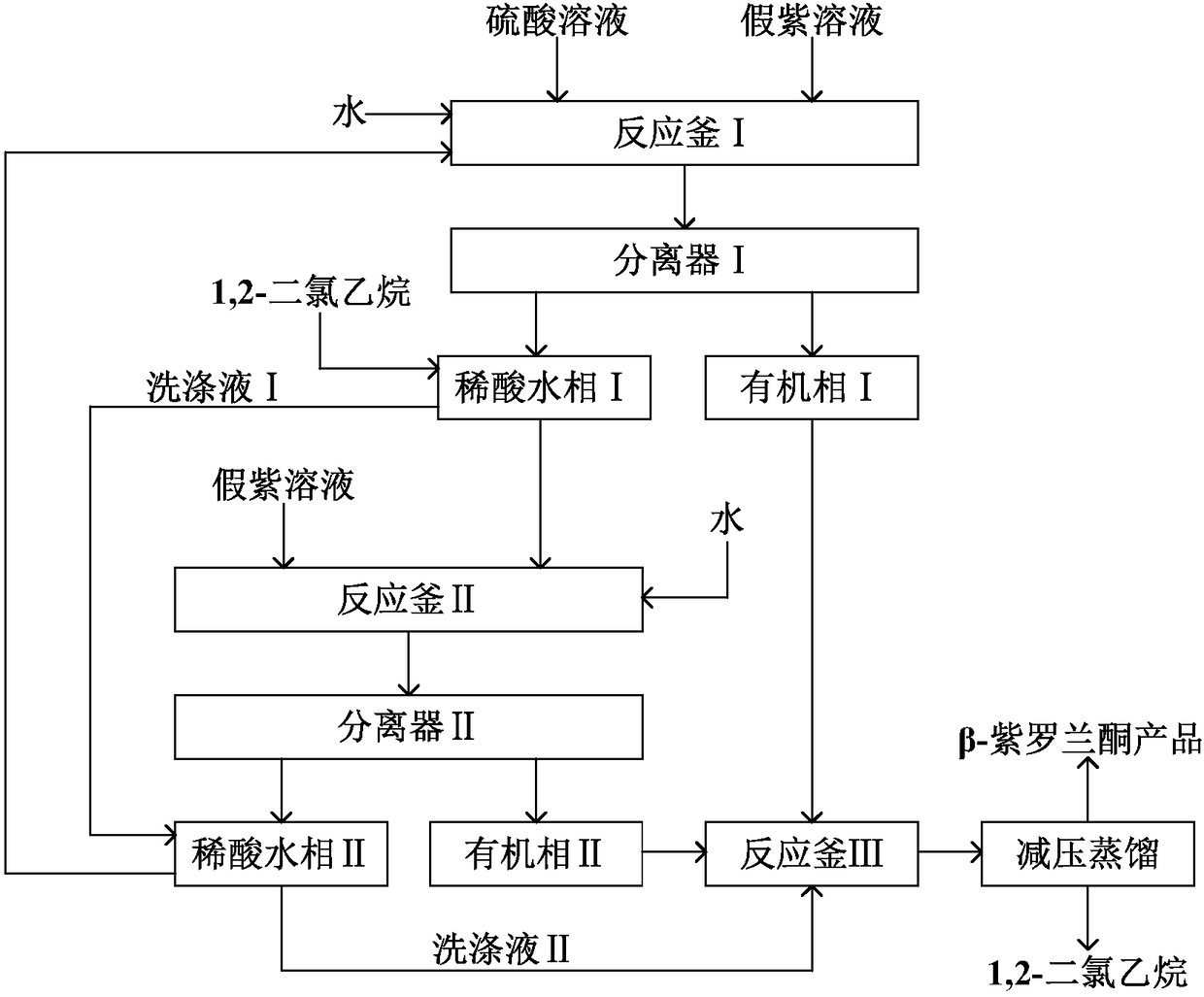

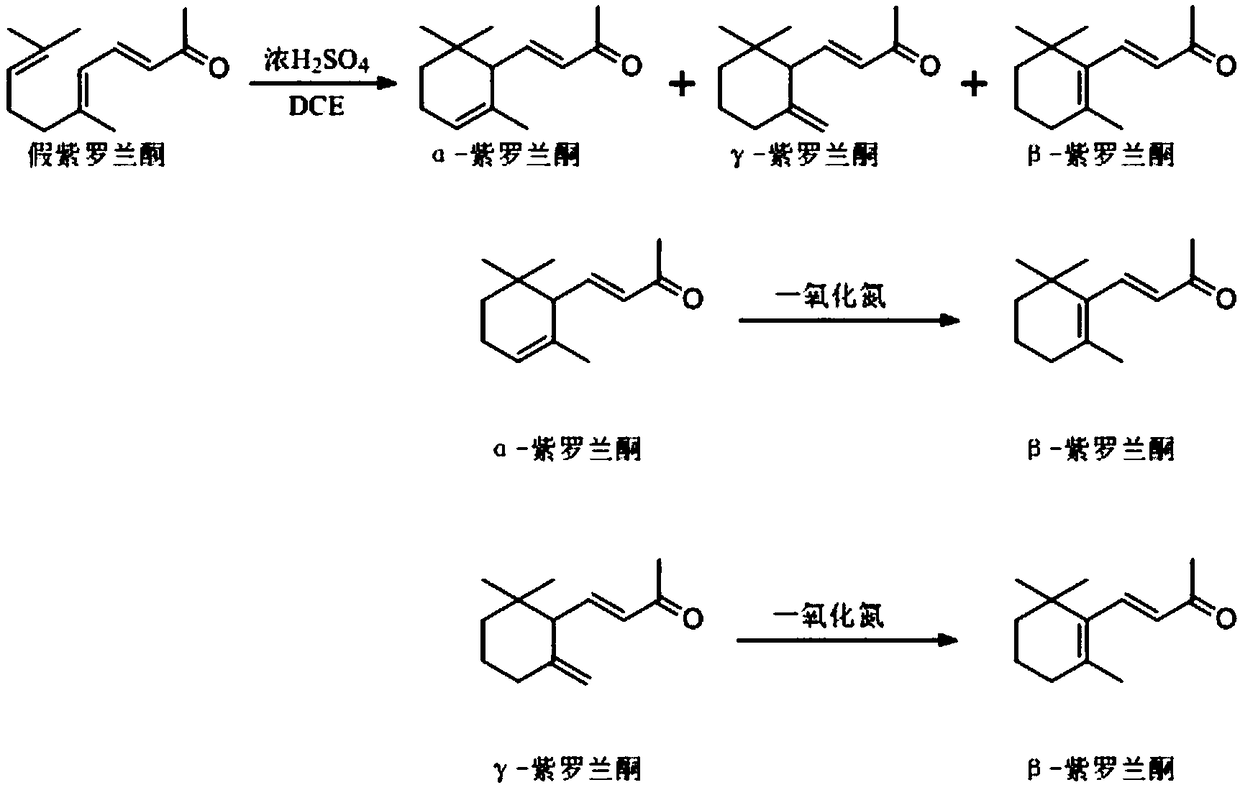

A technology for pseudo-ionone and ionone, which is applied in the field of preparing high-purity β-ionone, can solve the problems of producing a large amount of sulfuric acid waste water, harsh operating conditions, difficult separation, etc., and achieves reduced requirements for cyclization reaction conditions and improved utilization. The effect of reducing the rate and separation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 600g concentrated sulfuric acid (98wt%) is added in the reaction kettle I, start stirring, pass into the circulating cold water to regulate the temperature in the reaction kettle I, then by metering pump, 600g false ionone solution, hereinafter referred to as false purple solution (50wt%, The solvent is dichloroethane) and pumped into the reaction kettle Ⅰ to carry out the cyclization reaction. During the whole process of adding the false purple solution, the temperature in the reaction kettle Ⅰ is controlled at 7-39°C. After the addition of the false purple solution, continue at 28°C React for 10 minutes, then add 240g of water to dilute and quench. After quenching in the reaction kettle I, the reaction solution was separated by separator I to obtain 594g of organic phase I and 836g of dilute acid aqueous phase I (about 520mL, concentration 70.0%). The obtained dilute acid aqueous phase I was washed with 52 mL of dichloroethane, and the washing liquid I and the washed ...

Embodiment 2

[0046] 350g sulfuric acid solution (75wt%) is joined in the reaction kettle I, start to stir, pass into the temperature in the reaction kettle I of circulating cold water adjustment, then 700g pseudopurple solution (70wt%, solvent is dichloroethane) by metering pump Pump it into the reaction kettle Ⅰ for cyclization reaction. During the whole process of adding the false violet solution, the temperature in the reaction kettle Ⅰ is controlled at 5-32°C. After the addition of the false violet solution, continue the reaction at 0°C for 30 minutes, and then add 85g water for dilution and quenching. After quenching in the reaction kettle I, the reaction solution was separated by separator I to obtain 691 g of organic phase I and 428 g of dilute acid aqueous phase I (about 290 mL, concentration 60.3%). The obtained dilute acid aqueous phase I was washed with 45 mL of dichloroethane, and the washing liquid I and the washed dilute acid aqueous phase I were obtained after washing. Add ...

Embodiment 3

[0050] 470g sulfuric acid solution (85wt%) is joined in the reaction kettle I, start to stir, pass into the temperature in the reaction kettle I of circulating cold water adjustment, then by metering pump, 800g pseudopurple solution (10wt%, solvent is dichloroethane) Pump it into the reaction kettle Ⅰ to carry out the cyclization reaction. During the whole process of adding the false violet solution, the temperature in the reaction kettle Ⅰ is controlled at 25-47°C. After the addition of the false violet solution, continue the reaction at 50°C for 2 minutes, and then add 145g water for dilution and quenching. After quenching in the reaction kettle I, the reaction liquid was separated by separator I to obtain 791g of organic phase I and 608g of dilute acid aqueous phase I (about 390mL, concentration 64.9%). The obtained dilute acid aqueous phase I was washed with 48 mL of dichloroethane, and the washing liquid I and the washed dilute acid aqueous phase I were obtained after was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com