Method for synthesizing beta-ionone

A synthesis method and ionone technology, which are applied in chemical instruments and methods, preparation of organic compounds, preparation of carbon-based compounds, etc., can solve the problems of insufficient mixing of solvent and sulfuric acid, difficult control of reaction temperature, difficulty in amplification, and the like, To achieve the effect of convenient construction and operation, convenient and accurate adjustment and control, and inhibition of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

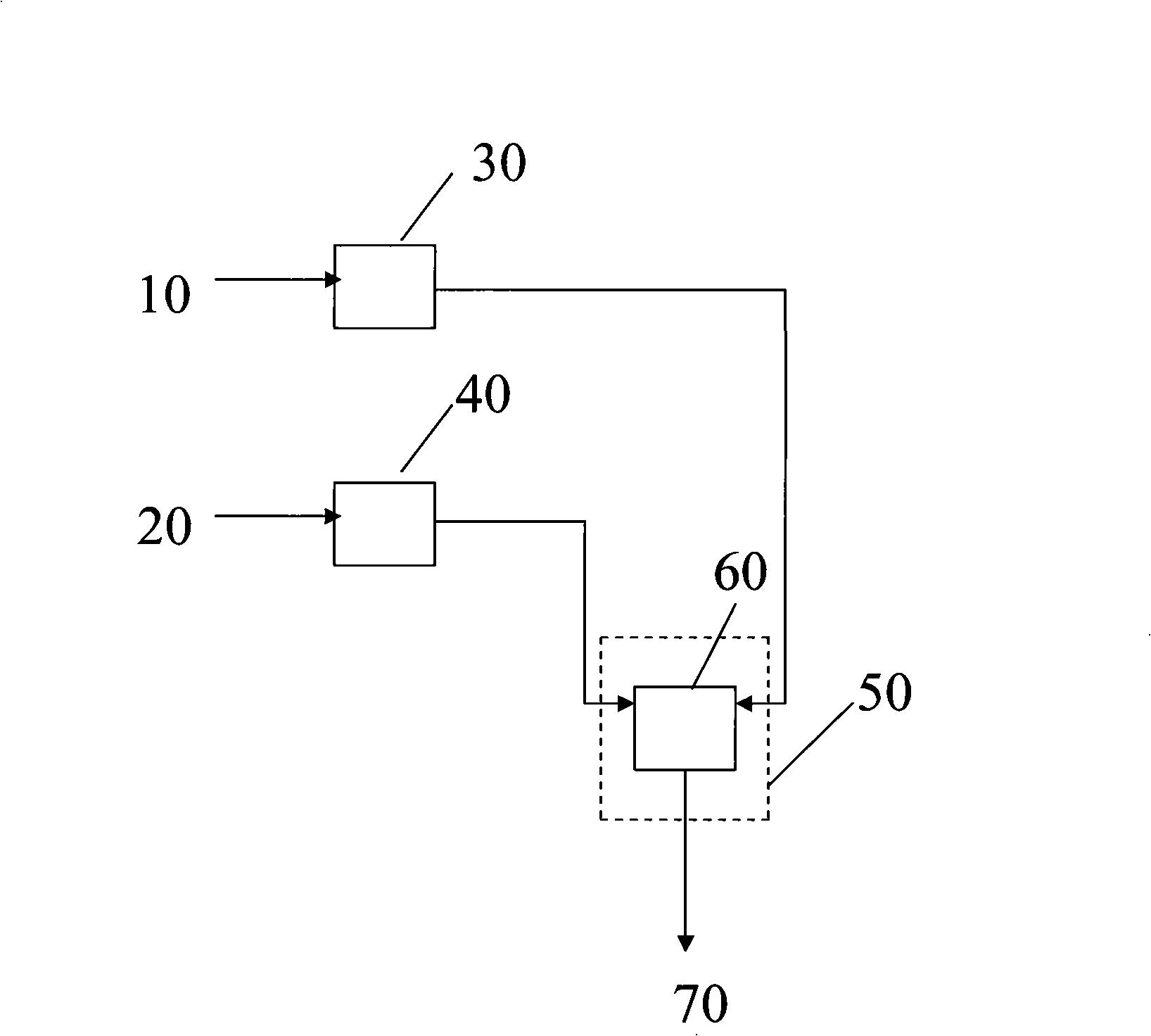

[0030] The chloroform / pseudo-ionone volume ratio is 3 / 1 mixture 10, and the concentrated sulfuric acid 20 of 95~98wt%, with the flow rate of 15ml / h respectively, simultaneously input with pump 30 and pump 40 and place in temperature control device 50 In the microreactor 60, the reaction temperature is controlled at -2°C. The channel structure of the microreactor is a comb type, and the channel size is 75 μm. The reaction product 70 was collected with ice water, and the organic phase obtained by solvent extraction was analyzed by gas chromatography. The conversion rate of the pseudoionone cyclization reaction was 97.91wt%, and the selectivity of β-ionone was 94.96wt%.

Embodiment 2

[0032] The chloroform / pseudo-ionone volume ratio is 3 / 1 mixture 10, and the concentrated sulfuric acid 20 of 95~98wt%, with the flow rate of 30ml / min respectively, simultaneously use pump 30 and pump 40 input to be placed in temperature control device 50 In the microreactor 60, the reaction temperature is controlled at -2°C. The channel structure of the microreactor is a comb type, and the channel size is 75 μm. The reaction product 70 was collected with ice water, and the organic phase obtained by solvent extraction was analyzed by gas chromatography. The conversion rate of pseudoionone cyclization reaction was 97.87wt%, and the selectivity of β-ionone was 92.93wt%.

Embodiment 3

[0034] The chloroform / pseudo-ionone volume ratio is 6 / 1 mixture 10, and the concentrated sulfuric acid 20 of 95~98wt%, with the flow rate of 30ml / h respectively, simultaneously input with pump 30 and pump 40 and place in temperature control device 50 In the microreactor 60, the reaction temperature is controlled at -2°C. The channel structure of the microreactor is a comb type, and the channel size is 75 μm. The reaction product 70 was collected with ice water, and the organic phase obtained by solvent extraction was analyzed by gas chromatography. The conversion rate of the pseudoionone cyclization reaction was 82.41wt%, and the selectivity of β-ionone was 94.72wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com