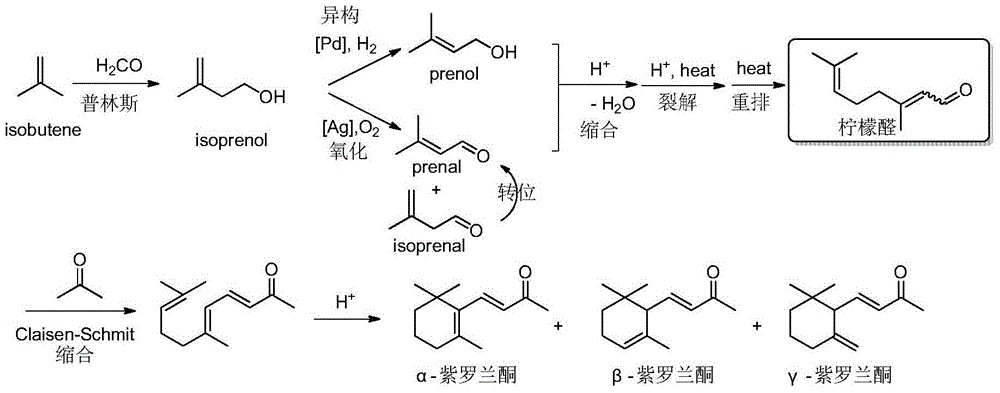

Method for continuously synthesizing beta-ionone through micro-chemical engineering technology

A technology of ionone and pseudoionone, which is applied in the field of cyclization of pseudoionone to synthesize β-ionone, can solve the problems of low application potential, reduced reaction selectivity and yield, and complicated operation, and achieve energy saving at low temperature , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

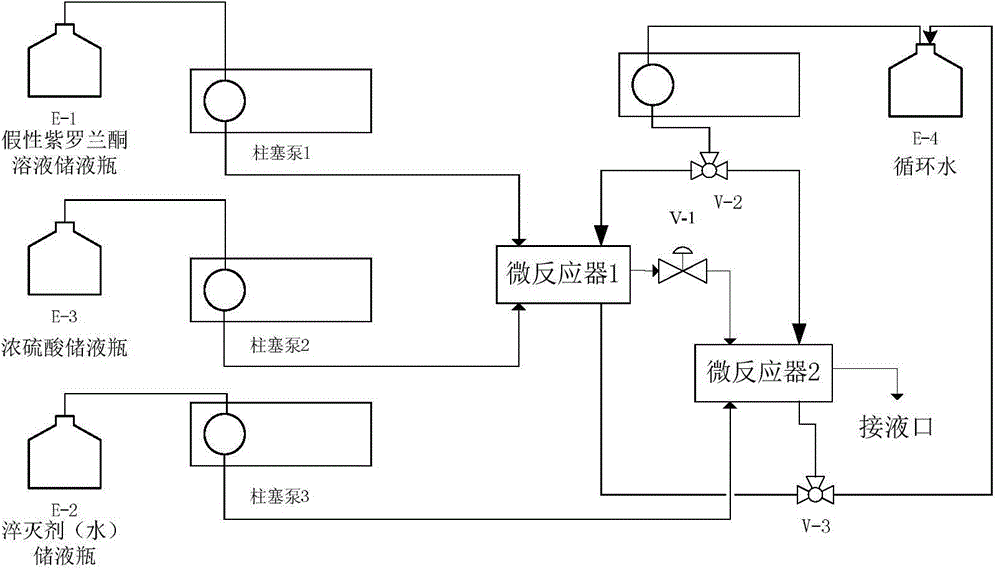

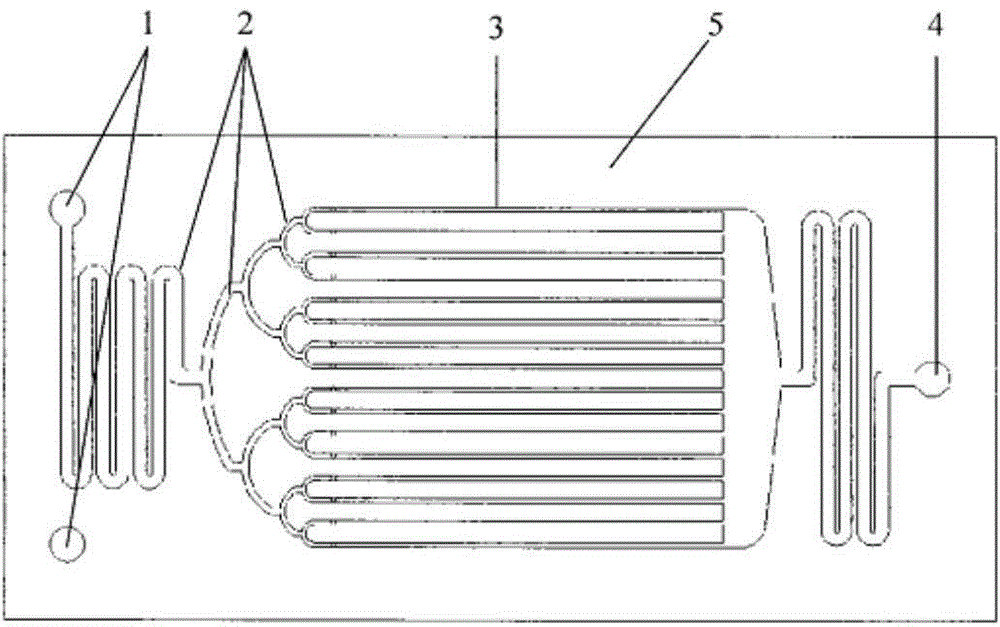

Embodiment 1

[0023]Put the mixture of dichloromethane / pseudo-ionone with a volume ratio of 1 / 1, and 95-98wt% concentrated sulfuric acid at the flow rates of 2.2mL / min and 1.7mL / min, respectively, and simultaneously use a plunger pump to input the integrated In the microreactor 1 of the temperature control device, the channel volume of the microreactor 1 is 0.283mL, the reaction temperature at the front end of the reactor 1 is controlled at 20°C, and the temperature at the rear end of the reactor 1 is controlled at 60°C. The channel structure of the channel of the microreactor is a fish raft structure. The rear end of microreactor 1 introduces microreactor 2 to introduce quenching water to quench the reaction, thereby obtaining the reaction mixture by controlling the reaction residence time. The volume flow of quenching water and the volume flow of sulfuric acid are controlled at a ratio greater than 3:1. within range. Connect the effluent for 3.5 minutes to obtain a milky purple-red liqui...

Embodiment 2

[0025] Put the mixture of dichloromethane / pseudo-ionone with a volume ratio of 1 / 1, and 95-98wt% concentrated sulfuric acid at the flow rate of 4.3mL / min and 2.7mL / min, respectively, and simultaneously use the plunger pump to input the integrated In the microreactor 1 of the temperature control device, the channel volume of the microreactor 1 is 0.283mL, the reaction temperature at the front end of the reactor 1 is controlled at 20°C, and the temperature at the rear end of the reactor 1 is controlled at 60°C. The channel structure of the channel of the microreactor is a fish raft structure. The back end of the microreactor 1 introduces a T-shaped micro-mixer with a diameter of 1.2 mm, which is used to introduce quenching water to quench the reaction, so that the reaction mixture is obtained by controlling the reaction residence time. The volume flow rate of the quenching water and the volume flow rate of sulfuric acid Control in the range greater than 3:1. The effluent was co...

Embodiment 3

[0027] Put the mixture of dichloromethane / pseudo-ionone with a volume ratio of 1:1, and 95-98wt% concentrated sulfuric acid at the flow rate of 10mL / min and 5.6mL / min, respectively, and simultaneously use the plunger pump to input the integrated temperature In the microreactor 1 of the control device, the channel volume of the microreactor 1 is 0.283mL, the reaction temperature at the front end of the reactor 1 is controlled at 20°C, and the temperature at the rear end of the reactor 1 is controlled at 50°C. The channel structure of the channel of the microreactor is a comb structure. The rear end of microreactor 1 introduces microreactor 2 to introduce quenching water to quench the reaction, thereby obtaining the reaction mixture by controlling the reaction residence time. The volume flow of quenching water and the volume flow of sulfuric acid are controlled at a ratio greater than 3:1. within range. Connect the effluent for 1.05 min to obtain a milky purple-red liquid, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com