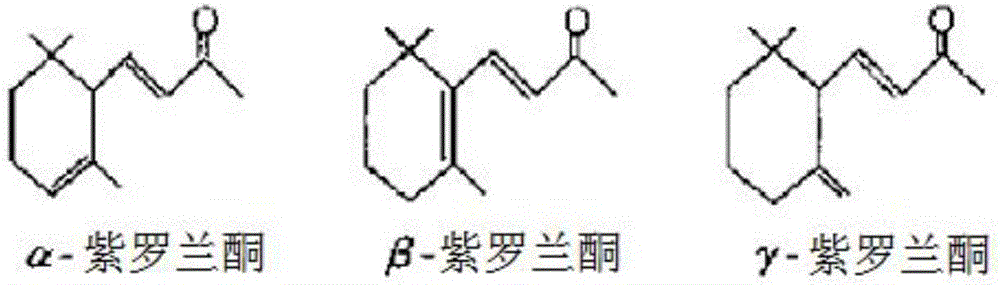

Device and method for continuously producing beta-ionone by using microchannel

A technology of ionone and pseudo-ionone, which is applied in the field of microchannel continuous production of β-ionone, can solve the problems of high price of phase transfer catalyst and anti-translocation agent, high energy consumption of ultrasonic equipment, and low production efficiency. , to achieve the effects of high yield, saving operating costs and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

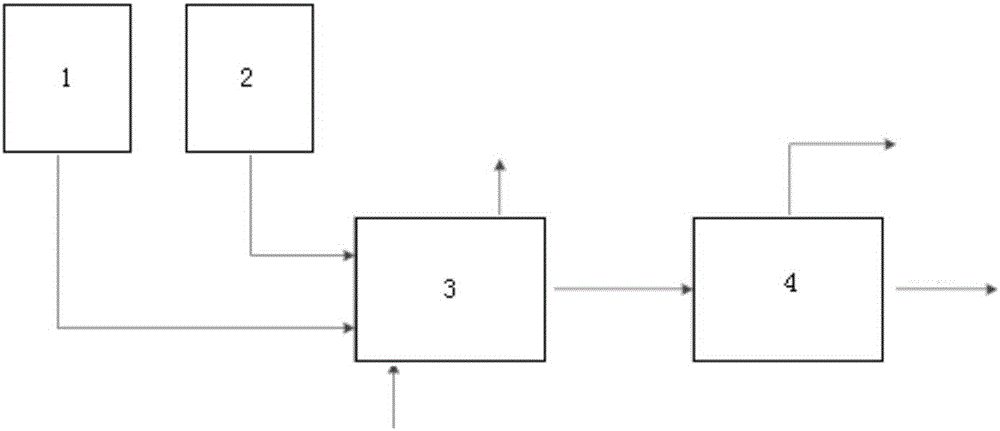

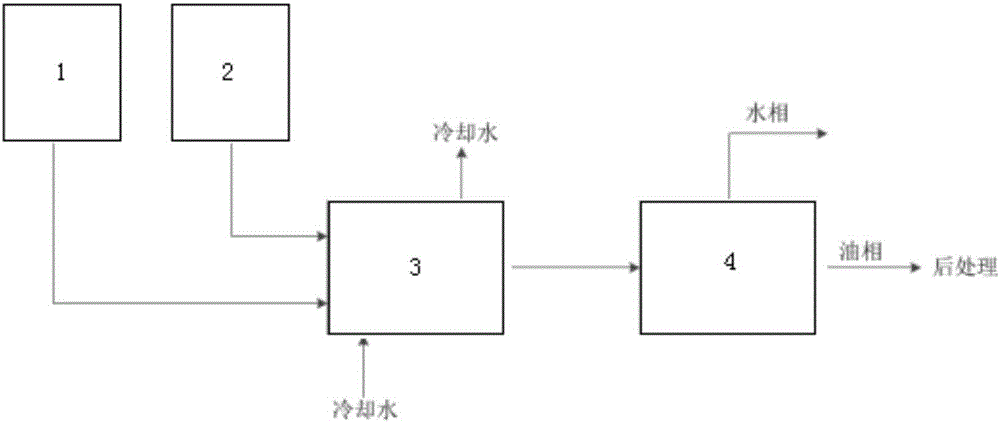

[0022] A method for the continuous production of beta-ionone with a microchannel reactor, see figure 2 , including the following steps:

[0023] (1) Use the above-mentioned device for continuously producing β-ionone with a microchannel reactor;

[0024] (2) the false ionone solution (stored in the false violet solution storage tank 1) of 50% volume fraction is made into pseudo-ionone with acetone, the pseudo-ionone solution and the vitriol oil (the concentrated sulfuric acid is stored in sulfuric acid In storage tank 2) pass in the microchannel reactor by two entrances of microchannel reactor 3 respectively, the flow of false ionone solution is 9L / h, the flow of vitriol oil is 18L / h, reacts at 30 ℃ (cooling 10 DEG C of water are passed into the microchannel reactor), after the product flows out of the microchannel reactor, the phase separator 4 is used to carry out the phase separation process to obtain the water phase recycling, and the oil phase containing β-ionone is succ...

Embodiment 2

[0027] A method for continuously producing β-ionone with a microchannel reactor, comprising the steps of:

[0028] (1) Use the above-mentioned device for continuously producing β-ionone with a microchannel reactor;

[0029] (2) Pseudo-ionone is made into a volume fraction of 70% pseudo-ionone solution with dichloromethane, and pseudo-ionone solution and vitriol oil are passed into the micro-channel reactor by two inlets of the micro-channel reactor respectively , the flow rate of pseudoionone solution is 9L / h, the flow rate of vitriol oil is 36L / h, reacts at 25 ℃ (cooling is passed into microchannel reactor with 5 ℃ of water), after the product flows out of microchannel reactor, separate The phase device (4) carries out the phase separation treatment to obtain the water phase recycling, and the oil phase containing β-ionone is washed with water, 2% sodium carbonate aqueous solution and water successively, and the dichloromethane is removed by distillation under reduced pressur...

Embodiment 3

[0032] A method for continuously producing β-ionone with a microchannel reactor, comprising the steps of:

[0033] (1) Use the above-mentioned device for continuously producing β-ionone with a microchannel reactor;

[0034] (2) Pseudo-ionone is made into a volume fraction of 30% pseudo-ionone solution with a mixed solvent (the mixed solvent is chloroform, carbon tetrachloride and 1,2-dichloride with a volume ratio of 1:1:1 Ethane composition), pseudo ionone solution and the vitriol oil pass in the micro channel reactor through two entrances of microchannel reactor (3) respectively, the flow of pseudo ionone solution is 9L / h, the flow of the vitriol oil is 9L / h, react at 28 DEG C (cooling is passed into microchannel reactor with 8 DEG C of water), after the product flows out of microchannel reactor, carry out phase separation treatment with phase separator (4) to obtain water phase recycling, obtain the - The oily phase of the ionone is washed with water, an aqueous sodium car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com