Bearing ring forging water cooling refining machine

A bearing ring, water cooling technology, used in manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of inability to guarantee product quality, long cooling method cycle, etc., and achieve the goal of refining material grains, improving service life and saving resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

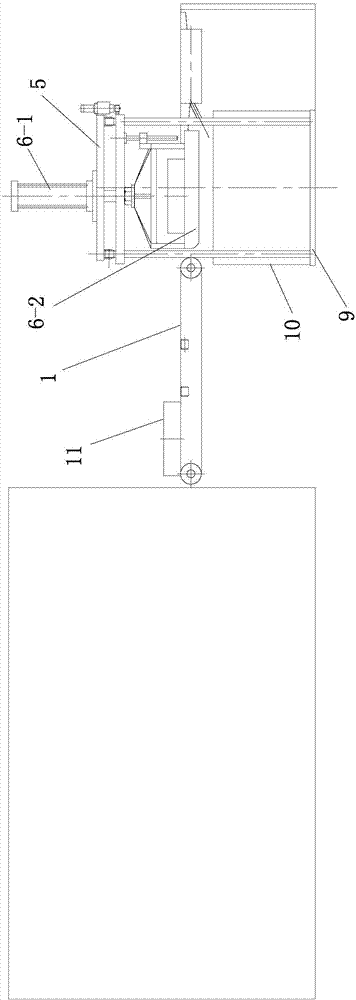

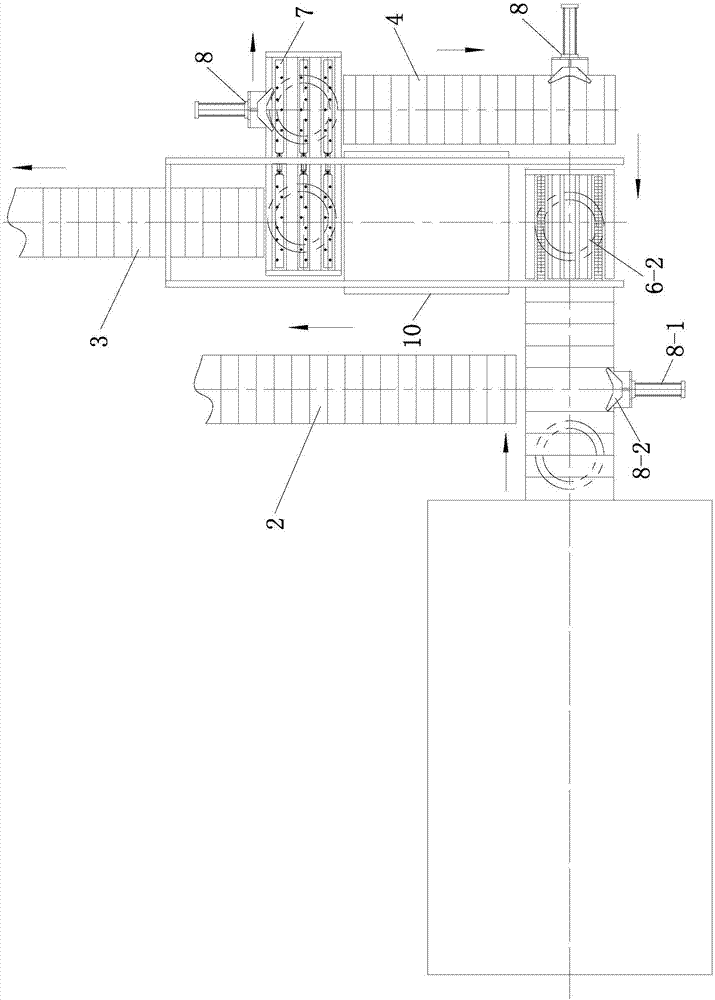

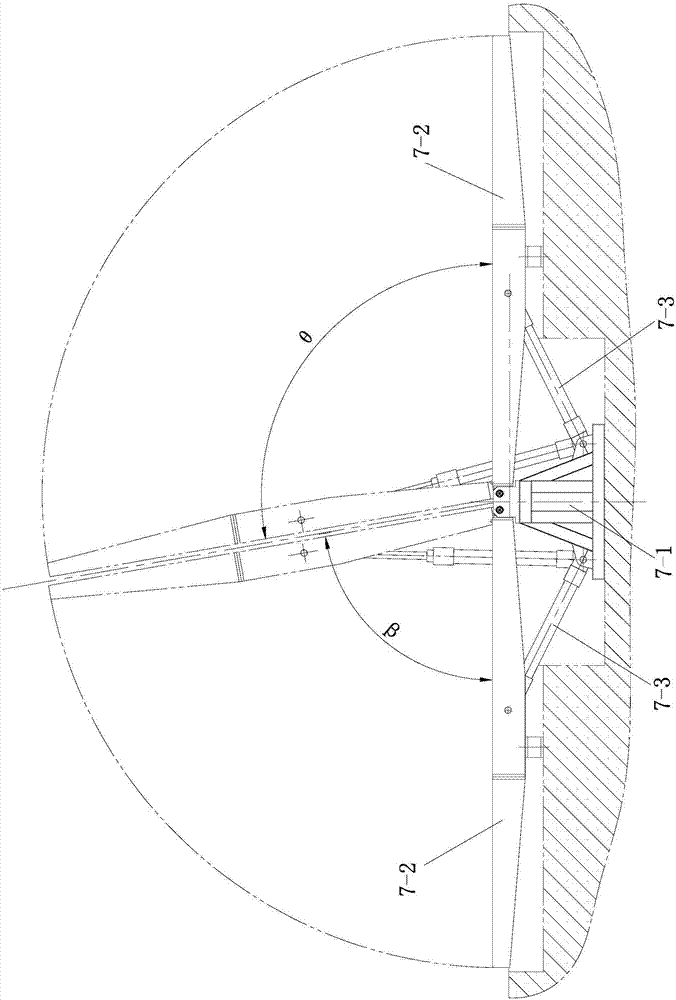

[0016] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

[0017] see Figure 1-Figure 3 Description, bearing ring forging water-cooled refining machine, which includes detection conveyor 1, waste transfer conveyor 2, qualified transfer conveyor 3, secondary water-cooled conveyor 4, transfer pulley 5, lifting load-bearing mechanism 6, turning Mechanism 7 and push piece mechanism 8;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com