Capacitive distance sensor

A distance sensor, capacitive technology, applied in the field of sensor design, can solve problems such as large error, power supply jitter measurement error, etc., to achieve the effect of improving suppression, improving measurement accuracy, and reducing parasitic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. The specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

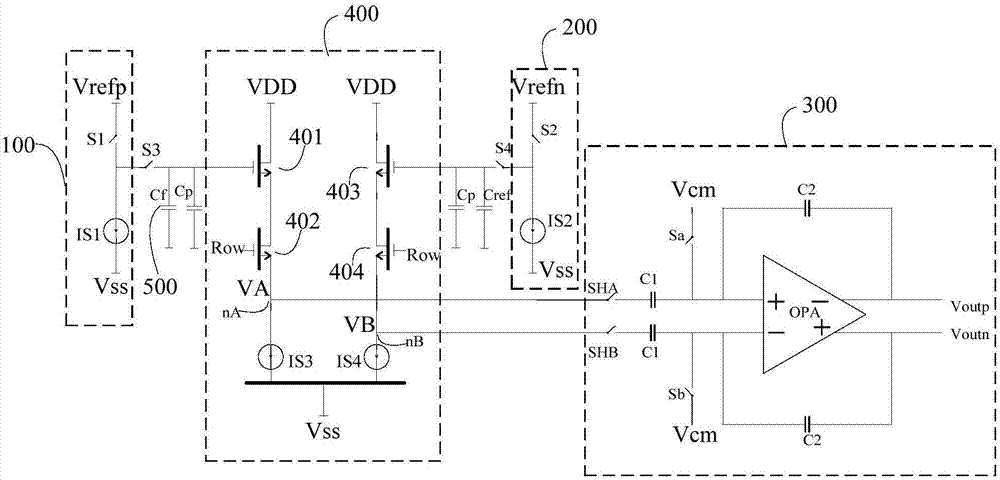

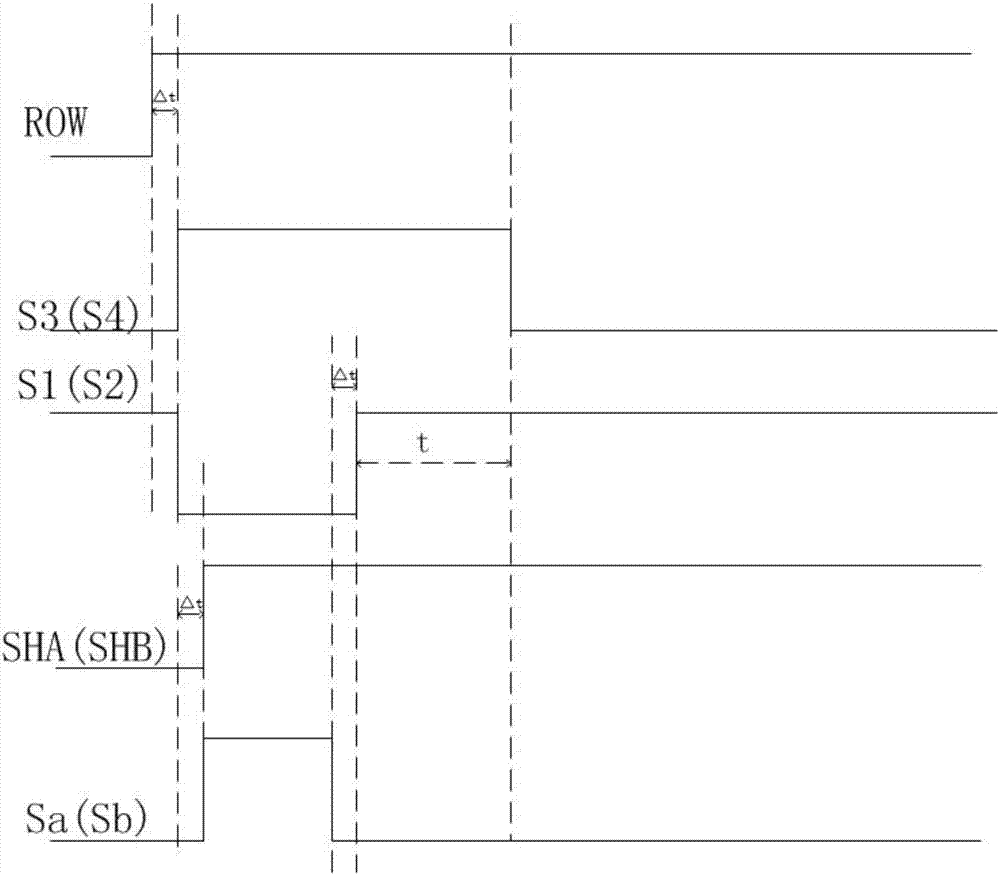

[0017] like figure 1 As shown, the capacitive distance sensor provided by the present invention specifically includes: a capacitance measurement plate 500 to be measured, a reference capacitance Cref, a switch S3, a switch S4, a charging / discharging circuit 100 for a capacitance to be measured, a charging / discharging circuit 200 for a reference capacitance, Fully differential sample / hold circuit 300 and source follower 400 .

[0018] The measured capacitance Cf is formed by the measured capacitance measuring plate 500 and the surface of the measured conductor. The under-test capacitance measuring plate 500 is connected to the under-test capacitance charging / discharging circuit 100 through a switch S3 , and is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com