Performance test for air leakage-resisting cell cementing test block prepared by using silica and alumina borax soil ceramic mierobeads for oil well

A technology of ceramic microbeads and anti-leakage gas, applied in the field of materials, can solve the problems affecting the compressive strength of cement test blocks, large change rate of cement slurry density, low compressive strength, etc., so as to improve the compressive strength and reduce the density. , the effect of anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

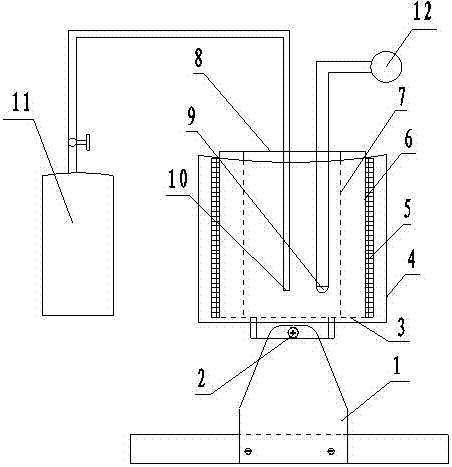

Image

Examples

Embodiment 1

[0030] The performance test of oil well leakage prevention gas cementing test block prepared by silicon-alumina-borax soil ceramic microbeads includes the following steps:

[0031] A. Preparation of silico-alumina borax closed-cell hollow ceramic microspheres:

[0032] The first step, the preparation of the base material: sample the silico-alumina borax soil powder with a particle size of 25µm, silica powder with a particle size of 40µm, and alumina powder with a particle size of 30µm according to the weight ratio: 70wt%:15wt%:15wt% to obtain mixed powder;

[0033] The second step, the modified firing of the base material: after the first step is mixed and stirred evenly, 5wt% of the total weight of the mixed powder is added to the reduced resin, stirred evenly in a mixer, and pressed into a billet with a compacting machine, at 150 ℃ Dry for 10 hours, heat preservation and firing in a 1500 ℃ reduction electric furnace for 4 hours, and obtain a modified silica-alumina-borax cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com