Silicon substrate MOS thin film luminescent device, preparation method thereof and full-spectrum thin film luminescent device

A light-emitting device, a silicon-based technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of small number of conductive channels, low luminous intensity, and low luminous efficiency, and achieve improved luminous efficiency, increased number, and increased luminous intensity. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

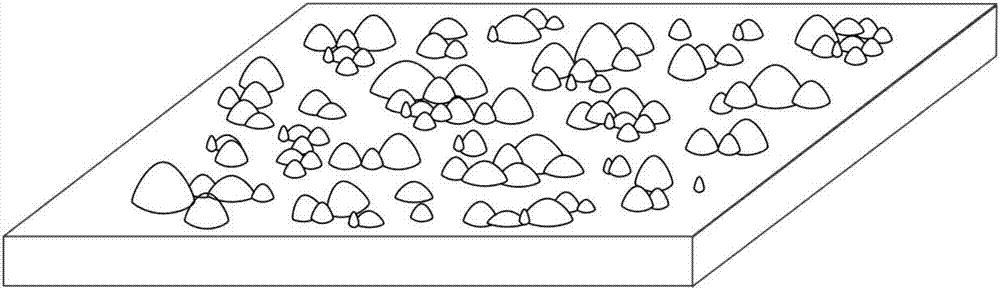

[0037] see figure 1 , a silicon-based MOS thin-film light-emitting device, using a p-type silicon wafer with a crystal orientation of as the substrate of the device, using 8% TMAH etching solution to etch the silicon substrate for 10 hours, or using 30% TMAH etching solution to etch the silicon substrate After etching for 2 hours, the etching temperature is 25°C at room temperature, and an irregular hill-shaped convex structure is prepared on the surface of the silicon substrate.

Embodiment 2

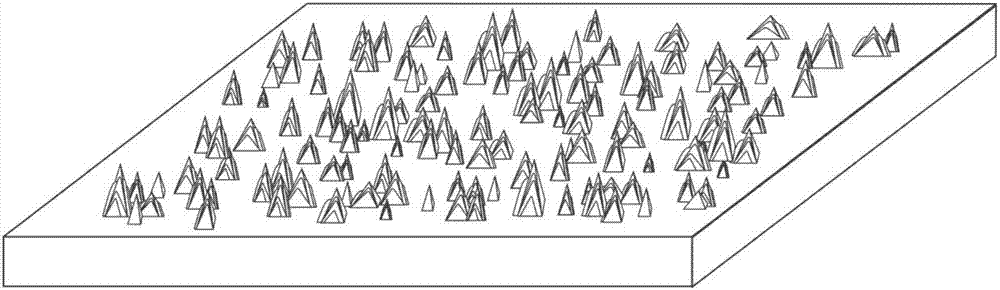

[0039] see figure 2 , a silicon-based MOS thin-film light-emitting device, using a p-type silicon wafer with a crystal orientation of as the substrate of the device, using 2% KOH solution to etch the silicon substrate for 45 minutes, and the etching temperature is 80 ° C, prepared on the surface of the silicon substrate Nested pyramid-shaped raised structures.

Embodiment 4

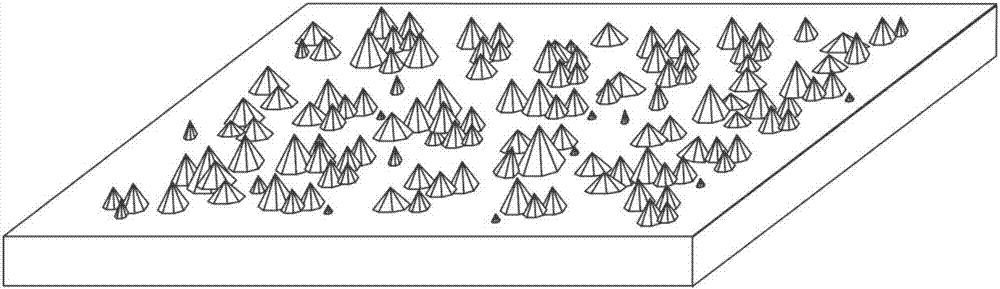

[0041] see image 3 , a silicon-based MOS thin-film light-emitting device, using a p-type silicon wafer with a crystal orientation of as the substrate of the device, using a composite solution NaOH:IPA=0.25%:6% to etch the silicon base for 15 minutes, and the etching temperature is 90 ° C. On the surface of the silicon base, a Pozierian pyramid-shaped convex structure is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap