Preparation method of membrane electrode and fuel cell

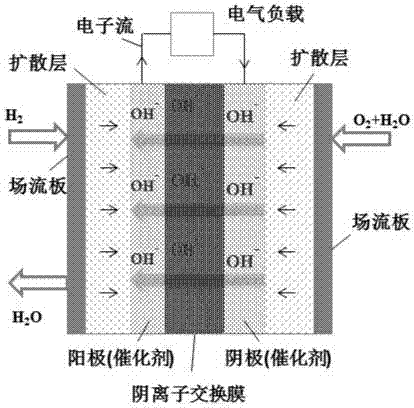

A membrane electrode and electrode technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of reducing battery performance, not improving the phase interface of the catalytic layer in essence, and increasing the thickness of the membrane electrode itself, so as to achieve small thickness, The effect of reducing the mass transfer resistance of the phase interface and the simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

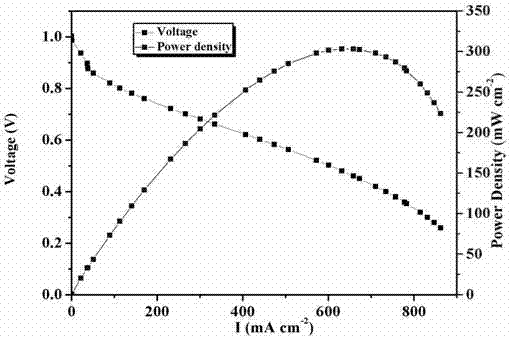

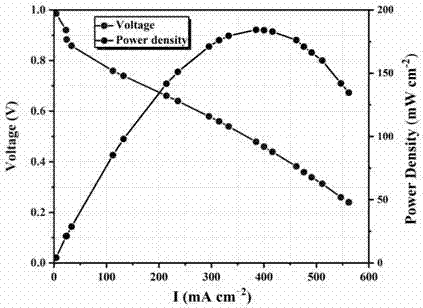

Embodiment 1

[0037] Dissolve 1g of brominated polyphenylene ether in 20mL of isopropanol at room temperature, stir well to obtain a uniform solution, then add 0.9g of dimethylaminoethyl methacrylate, react for 48 hours, and obtain a uniform coating solution after complete reaction ; The coating solution is coated on a glass plate, and dried at 50° C. to obtain an anion exchange membrane. Cut the anion exchange membrane to a size of 25cm 2 .

[0038] Dissolve 0.5g of brominated polyphenylene ether in 10mL of isopropanol at room temperature, stir well to obtain a uniform solution, then add 0.45g of dimethylaminoethyl methacrylate, react for 48 hours, and precipitate in water after complete reaction Filter to obtain anion exchange resin.

[0039] Weigh 0.02g each of the 60%Pt / C catalyst and the 60%PtRu / C catalyst with a weight content of 0.02g, respectively add 1.05g of isopropanol as a solvent, ultrasonicate for 60min, and then add 5wt% of the alcoholic solution of the above-mentioned anio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com