Manufacturing method of flexible ring of rolling electric rotary transmission device

A technology of transmission device and flexible ring, which is applied to circuits, electrical components, circuit/collector parts, etc., can solve the problems such as the large gap in the machining accuracy of anti-fatigue flexible rings and the immaturity of flexible thin-walled rings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

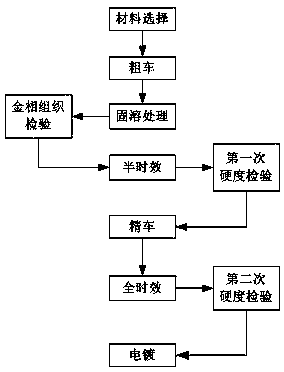

Image

Examples

Embodiment 1

[0027] A method for preparing a flexible ring of a rolling electrorotation transmission device, the specific steps are as follows:

[0028] A. Material selection: use beryllium bronze bar with strong fatigue characteristics and QBe17200 imported from the United States;

[0029] B. Rough turning: During the rough turning process, the beryllium bronze rod is processed into a beryllium bronze tube material with an outer circle and inner hole, and a machining allowance of 2mm is left for the inner hole and outer circle of the beryllium bronze tube material;

[0030] C. Solution treatment: solid solution treatment is carried out on the rough-carved beryllium bronze pipe material, so that the beryllium-rich phase in the beryllium bronze pipe material is solid-dissolved in the beryllium bronze matrix. The heating temperature is 750 ° C, and the constant temperature is maintained for 1 hour. Cool at a speed of ℃ / min. After the solution treatment is completed, the metallographic struct...

Embodiment 2

[0036] A method for preparing a flexible ring of a rolling electrorotation transmission device, the specific steps are as follows:

[0037] A. Material selection: use beryllium bronze bar with strong fatigue characteristics and QBe17200 imported from the United States;

[0038] B. Rough turning: During the rough turning process, the beryllium bronze rod is processed into a beryllium bronze tube material with an outer circle and inner hole, and a machining allowance of 2mm is left for the inner hole and outer circle of the beryllium bronze tube material;

[0039] C. Solution treatment: The beryllium bronze pipe material that has been roughed is subjected to solution treatment, so that the beryllium-rich phase in the beryllium bronze pipe material is solid-dissolved in the beryllium bronze matrix, the heating temperature is 770 ° C, and the constant temperature is kept for 1.5 hours. Rapid cooling at a rate of 20°C / min. After the solution treatment is completed, the metallograph...

Embodiment 3

[0045] A method for preparing a flexible ring of a rolling electrorotation transmission device, the specific steps are as follows:

[0046] A. Material selection: use beryllium bronze bar with strong fatigue characteristics and QBe17200 imported from the United States;

[0047] B. Rough turning: During the rough turning process, the beryllium bronze rod is processed into a beryllium bronze tube material with an outer circle and inner hole, and a machining allowance of 2mm is left for the inner hole and outer circle of the beryllium bronze tube material;

[0048] C. Solution treatment: The beryllium bronze pipe material that has been roughed is subjected to solution treatment, so that the beryllium-rich phase in the beryllium bronze pipe material is solid-dissolved in the beryllium bronze matrix. The heating temperature is 780 ° C, and the constant temperature is kept for 2 hours. Cool at a speed of ℃ / min. After the solution treatment is completed, the metallographic structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com