Combination formed connecting grouting sleeve and manufacturing method thereof

A technology for connecting sleeves and grouting sleeves, which is applied to structural elements, building components, building reinforcements, etc., can solve the problems of low production efficiency, high processing difficulty, difficult quality, etc., and achieves low production cost, simple production process, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A combined molding connection grouting sleeve

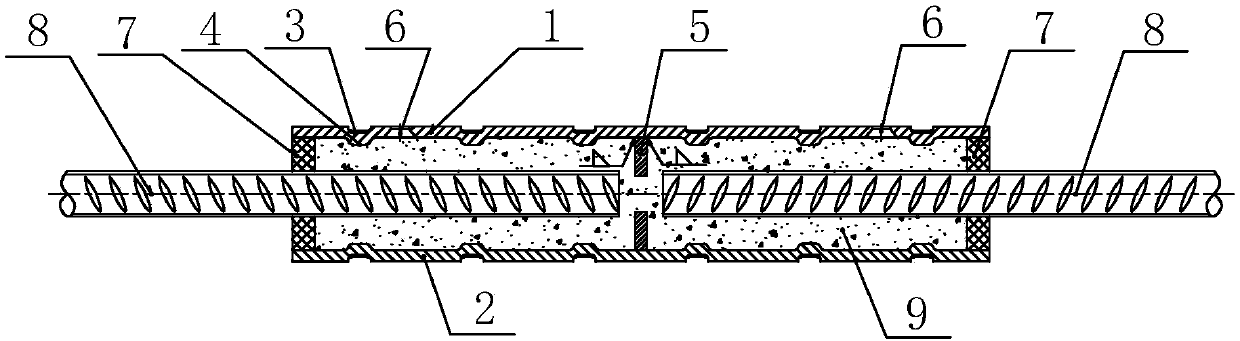

[0049] Such as figure 1 As shown, the combined molding connecting grouting sleeve includes connecting sleeve assembly I1, connecting sleeve assembly II2, two positioning plates 5 and two sealing rings 7 of separate structure; the connecting sleeve assembly I1, connecting sleeve Barrel assembly II2 is formed by stamping steel plate;

[0050] In the state of use, the two connecting sleeve assemblies I1 and II2 are fixedly connected by welding to form an integral tubular connecting sleeve, the positioning block 5 is located in the middle of the tubular connecting sleeve, and the sealing plates 7 are respectively located two ends of the tubular connection sleeve;

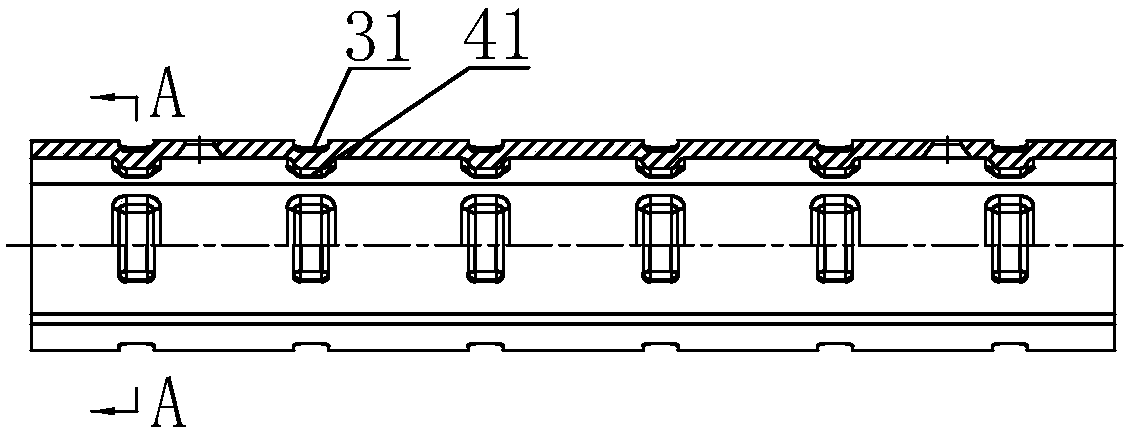

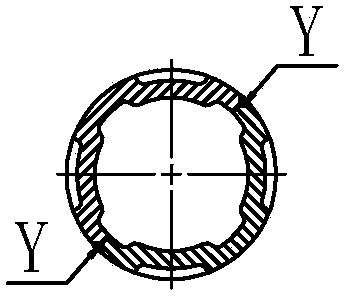

[0051] In order to ensure the bonding strength between the grouting material and the connecting sleeve and improve its pull-out resistance, there are ribs 41, bosses 42 or convex circles 43 on the inner surfaces of the connecting sleeve assembly I1 and connecting ...

Embodiment 2

[0057] A steel bar butt slurry anchor connection joint,

[0058] Such as figure 1 As shown, the steel bar butt grout anchor connection joint includes a connection grouting sleeve, a connected rib 8 and a grouting material 9, and the connection grouting sleeve is a combined connection grouting sleeve described in Embodiment 1. The combined molding connection grouting sleeve includes the connection sleeve assembly I1, the connection sleeve assembly II2, the positioning plate 5 and the sealing ring 7 of the separation structure; There are ribs 41, bosses 42 or convex circles 43 formed by stamping on the surface;

[0059] In the state of use, the two connecting sleeve components I1 and II2 are fixedly connected by welding to form an integral tubular connecting sleeve, and the positioning block 5 is located in the middle of the tubular connecting sleeve, and is separated from The two ends of the tubular connecting sleeve are inserted, and the sealing plates 7 are respectively loc...

Embodiment 3

[0063] A manufacturing method of a combined molding connecting grouting sleeve, that is, the manufacturing method of a combined molding connecting grouting sleeve described in Embodiment 1, which is to separately manufacture the connecting sleeve assembly I1, the connecting sleeve assembly II2 and the positioning block 5, and then, It is composed of a tubular connection sleeve that is fixedly connected into a whole by welding, including the following steps:

[0064] A. Material preparation, selected process and selected equipment:

[0065] A1. According to the diameter of the connected rib 8 and the size of the designed connecting sleeve, it is determined that the connecting sleeve is stamped and formed by two parts and then assembled and welded, and the stamping forming process is formulated;

[0066] A2. According to the selected stamping forming process, carry out mold making and select appropriate stamping equipment;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com