Excavated gravel-ultra fine full tailings pipeline self-flowing transportation filling system and method

A technology of full tailings and crushed stone, which is applied in the direction of filling materials, safety devices, mining equipment, etc., can solve the problems of ineffective use of waste rock, limited utilization rate of waste rock, and limited utilization rate of waste materials, etc., so as to reduce the cost of filling , low cost, and the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

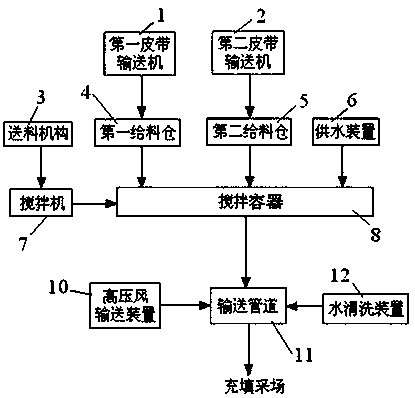

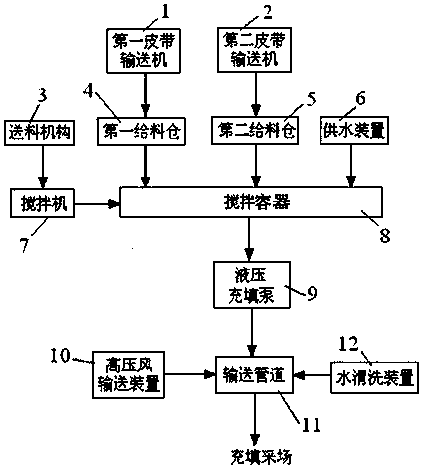

[0067] The water is sent into the mixing container 8, the hydraulic filling pump 9 and the delivery pipeline 11 sequentially through the water supply device 6, the water is tested for 3 minutes, and the filling pipeline is lubricated; Feed silo 4; send excavated gravel with a particle size of 16 to 20 mm into the second feeding silo 5 through the second belt conveyor 2; send cement into the mixer 7 through the feeding mechanism 3, and stir to obtain a weight concentration of 65% water in the stirring container 8 through the water supply device 6, when the water in the stirring container 8 reaches the material level of 1 / 3 of the stirring container, start the stirring container 8, and then put the cement slurry in the mixer 7, the first feed The ultra-fine full tailings in the silo 4 and the excavated gravel in the second feed bin 5 are successively and continuously sent into the mixing container 8, and the weight ratio of the ultrafine full tailings sent into the mixing contain...

Embodiment 2

[0073]Start the water supply device 6, and the water supply device 6 sends water into the stirring container 8, the hydraulic filling pump 9 and the delivery pipeline 11 in sequence, test the water for 5 minutes, and lubricate the filling pipeline; send the ultrafine tailings through the first belt conveyor 1 into the first feeding bin 4; through the second belt conveyor 2, the excavated gravel with a particle size of 16-20mm is sent into the second feeding bin 5; through the feeding mechanism 3, the cement is sent into the mixer 7, and stirred to obtain the weight Concentration is the cement slurry of 7.2%; Inject water in the mixing container 8 through the water supply device 6, after the water in the stirring container 8 reaches the material level of 1 / 3 of the mixing container, then the cement slurry in the mixer 7, the first feed The ultrafine tailings in the silo 4 and the excavated gravel in the second feed bin 5 are successively and continuously sent into the mixing con...

Embodiment 3

[0075] Start the water supply device 6, and the water supply device 6 sends water into the stirring container 8, the hydraulic filling pump 9 and the delivery pipeline 11 in sequence, test the water for 4 minutes, and lubricate the filling pipeline; send the ultrafine tailings through the first belt conveyor 1 into the first feeding bin 4; through the second belt conveyor 2, the excavated gravel with a particle size of 16-20mm is sent into the second feeding bin 5; through the feeding mechanism 3, the cement is sent into the mixer 7, and stirred to obtain the weight Concentration is the cement slurry of 68.5%; Inject water into the stirring container 8 through the water supply device 6, after the water in the stirring container 8 reaches the material level of 1 / 2 of the stirring container, then put the cement slurry in the mixer 7, the first feed The ultra-fine tailings in the silo 4 and the excavated gravel in the second feed bin 5 are continuously sent into the mixing contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com