In-situ synthesizing method of chirally-modified palladium nanometer material of different morphologies

A synthesis method and in-situ synthesis technology, applied in the direction of nanotechnology, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

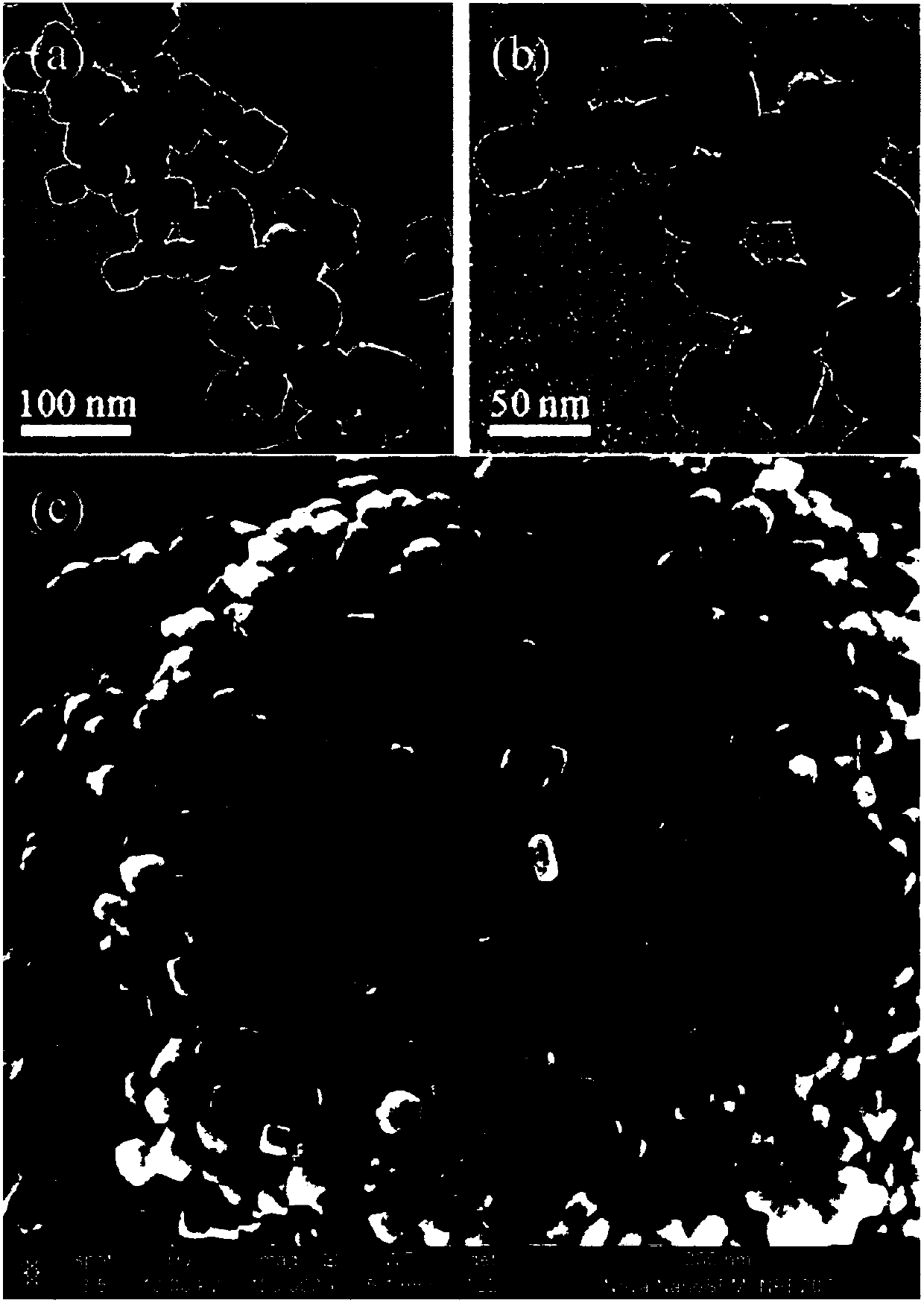

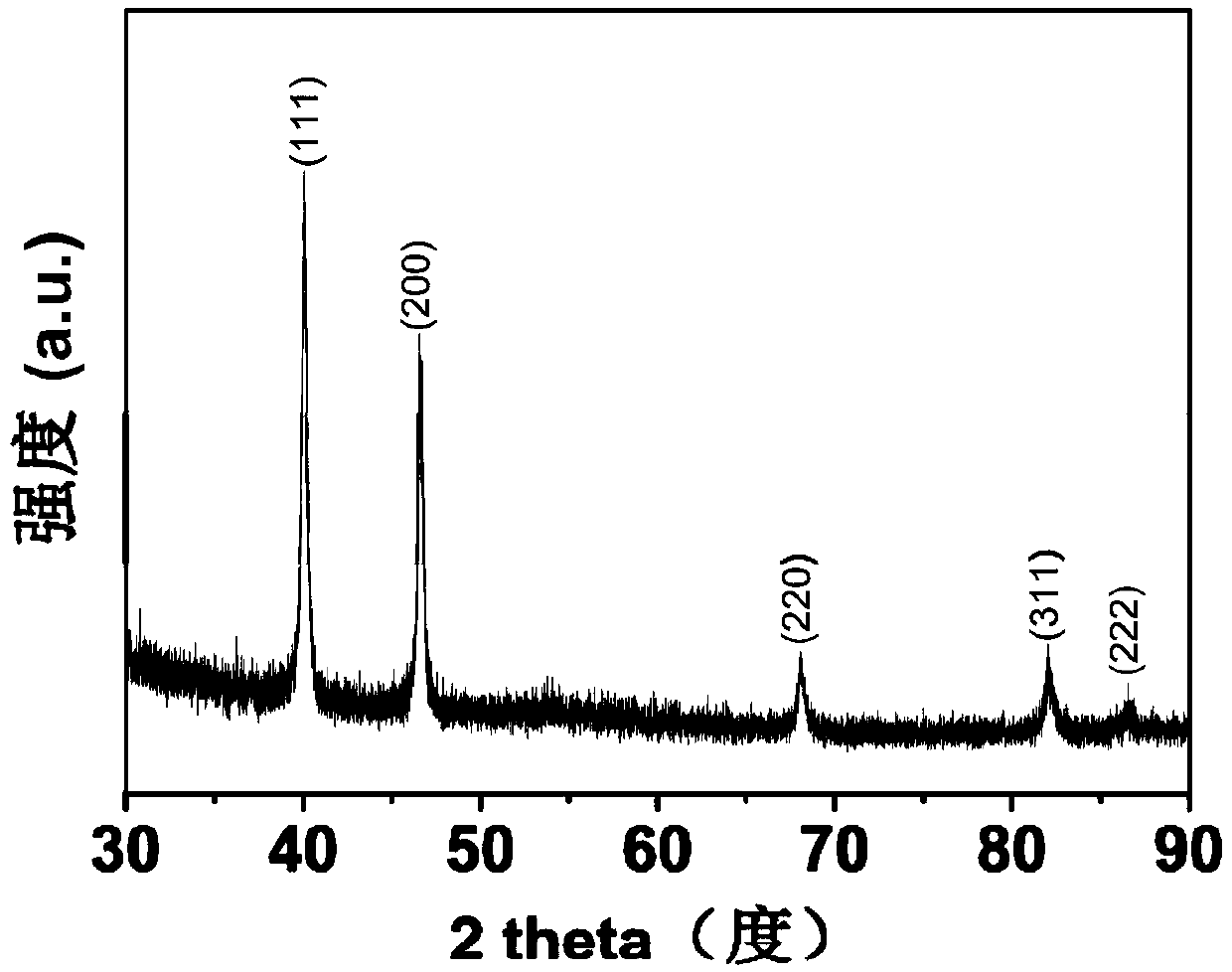

[0024] Example 1: Add 400 mg proline to 100 mL deionized water, stir and dissolve at 50 °C under a nitrogen atmosphere at normal pressure, add 800 uL 0.1 M ascorbic acid after 20 min, stir evenly, add 5 mL 10 mM chloropalladium acid , and stirred for 30 min. After the reaction, the product was collected by centrifugation, the sample was washed twice with water and twice with ethanol, and the obtained product was dispersed in ethanol. The product characterization results were as follows: Figure 1-2 .

Embodiment 2

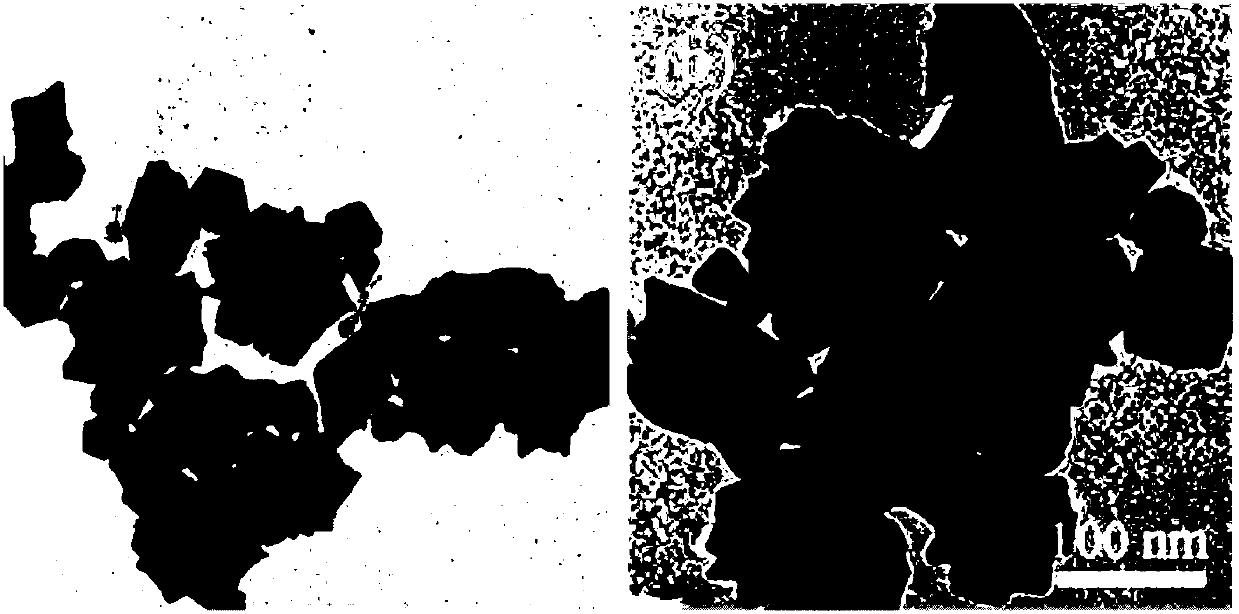

[0025] Example 2: 75 mg of tartaric acid was added to 100 mL of deionized water, stirred and dissolved at 40 °C under a nitrogen atmosphere at normal pressure, 5 mL of 10 mM chloropalladium acid was added after 20 min, stirred for 5 min, and 1 mL of 0.1 M ascorbic acid was added, The reaction was stirred for 60 min. After the reaction, the product was collected by centrifugation, the sample was washed twice with water and twice with ethanol, and the obtained product was dispersed in ethanol. The product characterization results were as follows: image 3 .

Embodiment 3

[0026] Example 3: 75 mg of tartaric acid was added to 100 mL of deionized water, stirred and dissolved at 90 °C under a nitrogen atmosphere at normal pressure, 5 mL of 10 mM chloropalladium acid was added after 20 min, stirred for 5 min, and 1 mL of 0.1 M ascorbic acid was added, The reaction was stirred for 60 min. After the reaction, the product was collected by centrifugation, the sample was washed twice with water and twice with ethanol, and the obtained product was dispersed in ethanol. The product characterization results were as follows: Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com