LTCC ultrafast machining system and method thereof

A processing system and vertical technology, applied in the field of LTCC ultra-fast processing system, can solve the problems that the processing efficiency is difficult to exceed 1000 holes/second, the spacing accuracy of micro-vias is prohibitive, and the micro-vias are difficult to meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations are now described in detail.

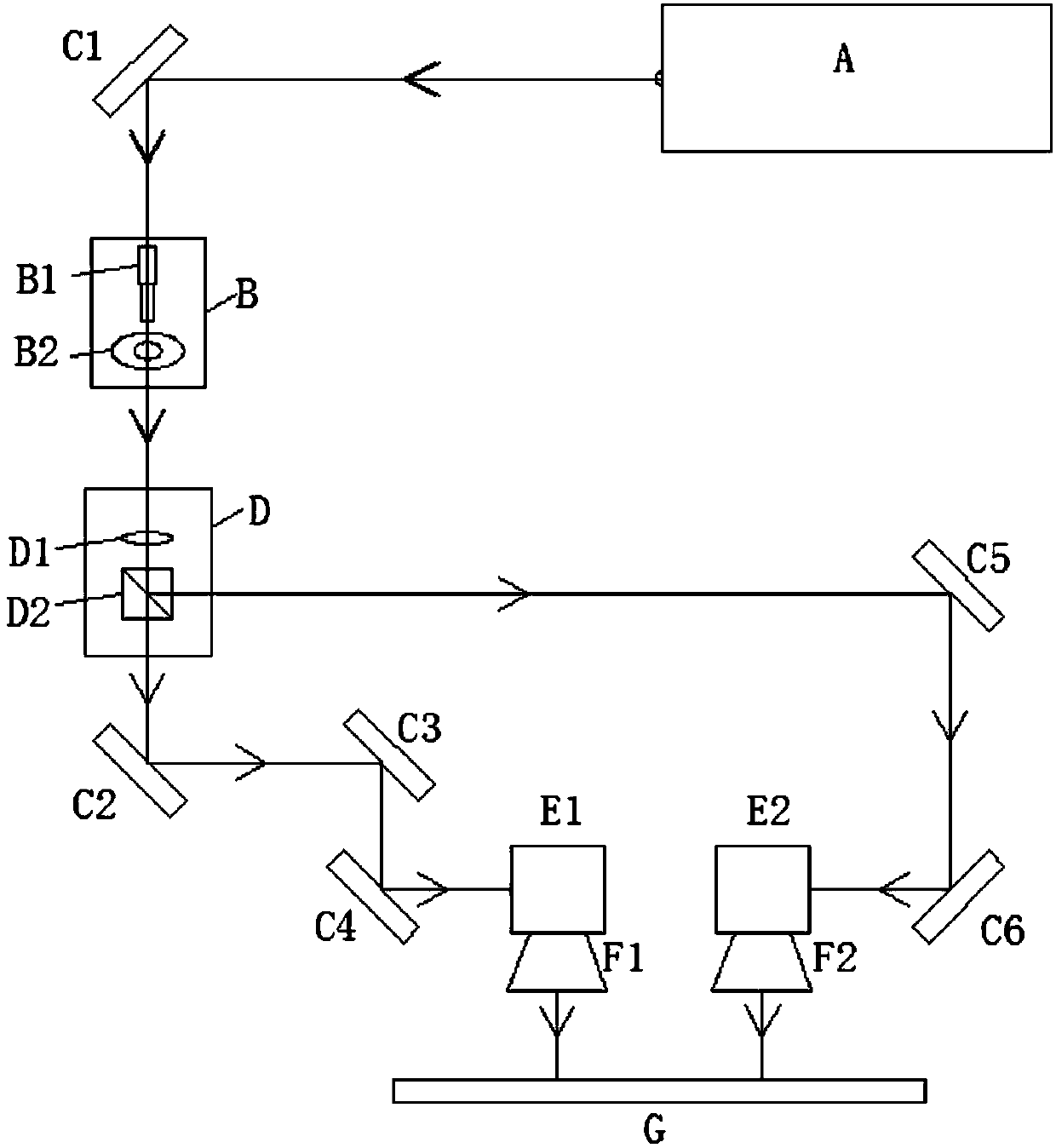

[0037] Such as figure 1 As shown, the LTCC ultra-fast processing system is set according to the direction of the optical path:

[0038] Laser A is an ultrafast picosecond laser with a narrow pulse width, and the output beam has a high repetition rate; the optical path at the output end of the laser A is equipped with an optical gate to control the switching light;

[0039] The first reflection unit, including the first reflection mirror C1 arranged in the direction of the optical path, injects the beam output from the laser A into the beam shaping module B;

[0040] Beam shaping module B includes beam expander B1 and filter B2. Beam expander B1 is placed on the optical path in reverse to expand the beam and change the size of the beam expansion spot. Filter B2 is arranged on the expander After the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com