Clutch steel sheet processing method

A processing method and clutch technology, applied in clutches, friction clutches, mechanical drive clutches, etc., can solve the problems of wasting steel and high production costs, and achieve the effects of cost saving, strength and hardness improvement, and resource saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

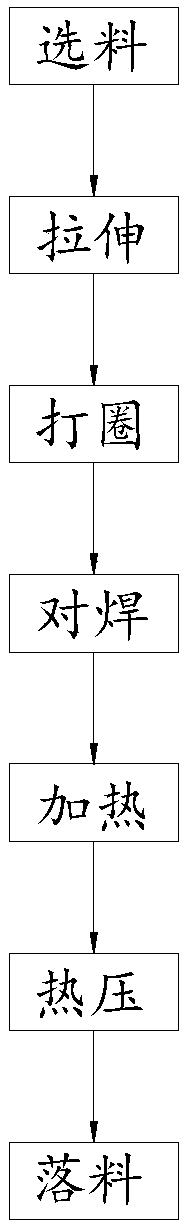

[0036] Such as figure 1 Shown, a kind of clutch steel sheet processing method comprises the following steps:

[0037] A. Material selection: select a disc with a diameter of 6.5mm-8.5mm;

[0038] B. Stretching: Use a cold drawing machine to stretch the disc circle, and the diameter after stretching is 4.5mm-6mm; the outer oxide shell can be removed to make the outside smoother, making the required materials more accurate in all aspects;

[0039] C. Looping: use a looping machine to circle the stretched disc into a torus, the diameter of the torus is 85mm-120mm, and the diameter of the torus directly refers to the diameter of the inner ring of the torus;

[0040] D. Butt welding: Butt welding is carried out on the disconnected port of the torus, so that the disconnected port of the torus is connected as a whole, and the butt joint of the butt welding place is neat and not in place;

[0041] E. Heating: Heat the torus after butt welding in a high-frequency furnace, the heatin...

Embodiment 2

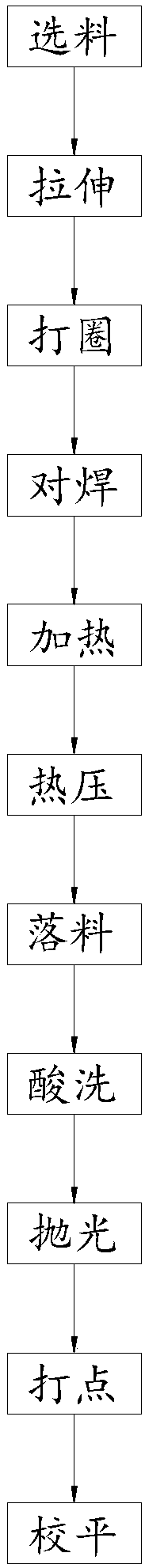

[0045] Such as figure 2 Shown, a kind of clutch steel sheet processing method comprises the following steps:

[0046] A. Material selection: select a disc with a diameter of 6.5mm;

[0047] B. Stretching: use a cold drawing machine to stretch the disc circle, and the diameter after stretching is 5.3mm;

[0048] C, ringing: use a ringing machine to circle the stretched disc into a ring, and the diameter of the ring is 85mm;

[0049] D. Butt welding: Butt welding is carried out on the disconnected port of the torus, so that the disconnected port of the torus is connected as a whole, and the butt joint of the butt welding place is neat and not in place;

[0050] E. Heating: heat the torus after butt welding in a high frequency furnace, the heating temperature is 700°C, and the heating time is 2s;

[0051] F, hot pressing: the heated torus is pressed into a blank 1 with a thickness of 2mm by a hot press, and the blank 1 becomes a circular sheet structure;

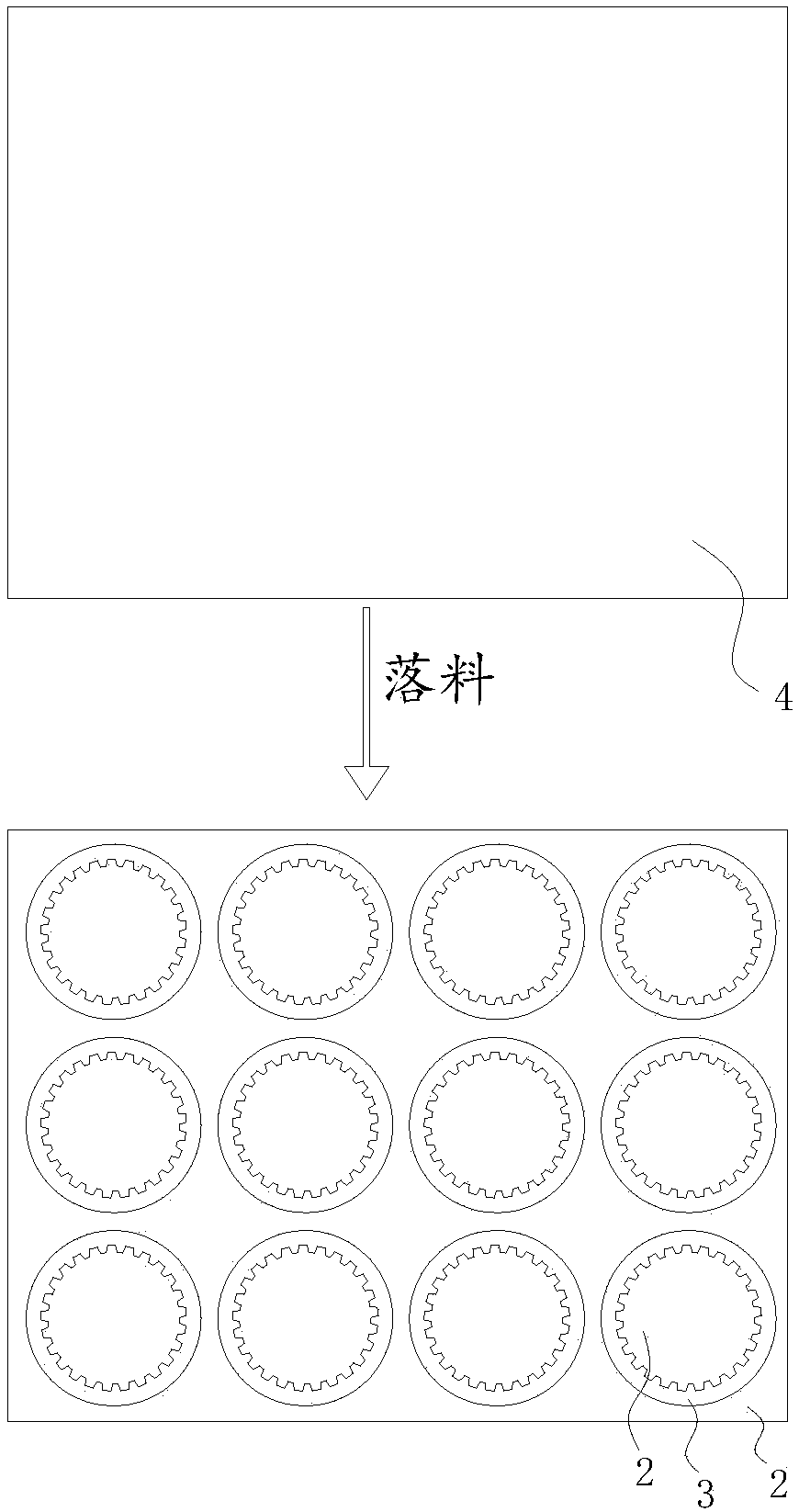

[0052] G. Blanking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com