Visual carbon material structure and preparation method thereof

A technology of material structure and visualization of carbon, applied in chemical instruments and methods, nano-carbon, inorganic chemistry, etc., can solve problems such as high cost, complicated processing process, and error-prone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In describing embodiments of the invention, specific terminology is employed for the sake of clarity. However, it is not intended that the invention be limited to the specific terms so chosen. It is to be understood that each specific element includes all technical equivalents which operate in a similar method to achieve a similar purpose.

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

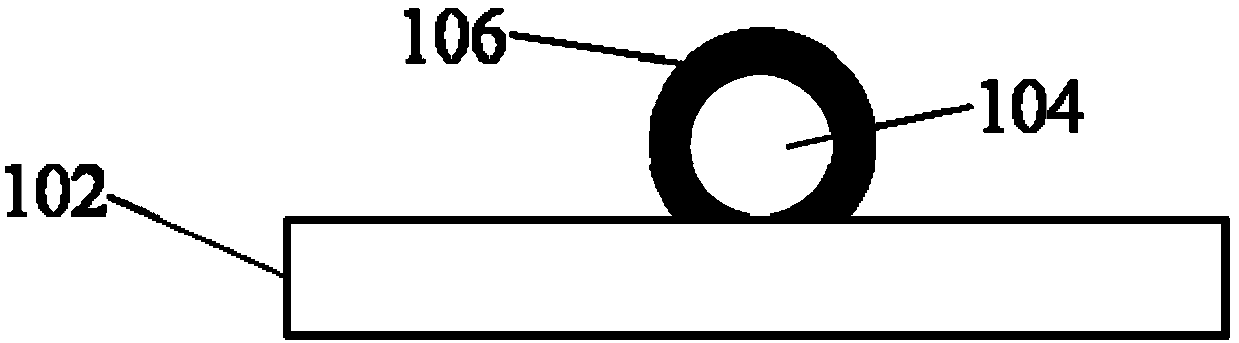

[0020] figure 1 To visualize the schematic diagram of the carbon material structure, its structure consists of the following parts:

[0021] 1. Carbon nanomaterial growth substrate 102: a variety of common substrates can be selected, and its characteristics are: highly flat surface, high temperature resistance, stable physical and chemical properties, etc., such as Si / SiO x , SiC, quartz, mica, corundum, ceramics, metal, etc.; in order to enhance the reflection of light and enhance the contrast of imaging, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com