Novel super-hydrophobic coating as well as preparation method and application thereof

A technology of super-hydrophobic coatings and super-hydrophobic coatings, applied in antifouling/underwater coatings, anti-corrosion coatings, alkali metal silicate coatings, etc., can solve the problem of harsh preparation process conditions of super-hydrophobic films, restricting industrial applications, and transparency In order to achieve the effect of various application methods, low cost and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A new type of superhydrophobic coating, the superhydrophobic coating is composed of glass glue, organic solvent (ethanol) and superhydrophobic SiO 2 powder prepared.

[0027] The preparation method of described novel superhydrophobic coating comprises the following steps:

[0028] 1) Mix glass glue and organic solvent (mixed solvent of acetone and ethanol, mixing volume ratio 1: 3 to get glass glue solution;

[0029] 2) Add superhydrophobic SiO to the glass glue solution 2 The suspension obtained by mixing the powder is the superhydrophobic coating.

[0030] In step 1), the mass fraction of glass glue in the glass glue solution is 1.5%.

[0031] In step 1), when mixing, first ultrasonically disperse for 20 minutes, and then magnetically stir for 10 minutes.

[0032] Step 2), superhydrophobic SiO 2 The mass fraction of the powder in the suspension is 5%; the superhydrophobic SiO 2 The powder is added by ultrasonic mixing, and the ultrasonic time is 20min.

Embodiment 2

[0034] A novel superhydrophobic coating and preparation method thereof, differs from Example 1 in that the organic solvent is a mixed solvent of acetone and ethanol, and the mixing volume ratio is 1:1. In step 1), the mass fraction of glass glue in the glass glue solution is 1%; in step 2), the superhydrophobic SiO 2 The mass fraction of the powder in the suspension is 0.5%; the rest are the same as in Example 1.

Embodiment 3

[0036] A novel superhydrophobic coating and preparation method thereof, the difference from Example 1 is that the organic solvent is toluene; in step 1), the mass fraction of glass glue in the glass glue solution is 3%; in step 2), Superhydrophobic SiO 2 The mass fraction of the powder in the suspension is 3%; the rest are the same as in Example 1.

[0037] Performance testing and application:

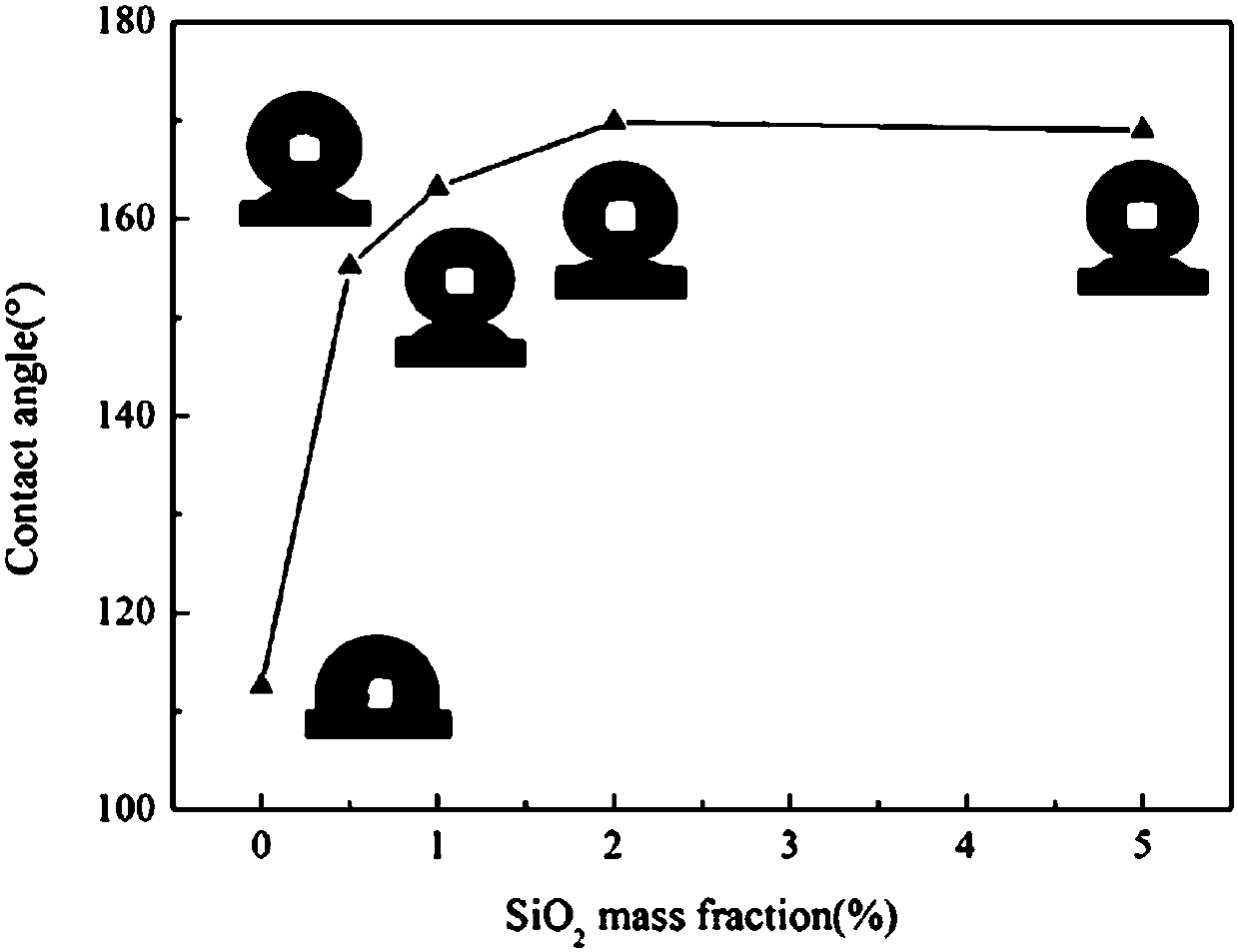

[0038] 1. SiO in suspension 2 The effect of different mass fractions on the contact angle and light transmittance of the coating

[0039] When the mass fraction of glass glue in the glass glue solution is constant (1.5%), changing the SiO 2 The mass fraction of the mass fraction is prepared respectively when the mass fraction is 0.5%, 1%, 2%, 5%, 10%, and 20%. When the mass fraction of the glass glue is changed to 10%, 20%, and 30%, respectively, change SiO2 2 The mass fraction of the obtained coatings is recorded as sample 1 to sample 9 successively. Each coating is coated on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com