A construction method of graphene oxide-based thermal insulation mortar

A thermal insulation mortar, graphene-based technology, applied in the directions of thermal insulation, climate change adaptation, covering/lining, etc., can solve the problems of hollowing and loosening of thermal insulation mortar layer, reducing thermal performance and durability, and complicated construction, and achieves economical savings. The effect of labor cost, high utilization rate and convenient construction and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

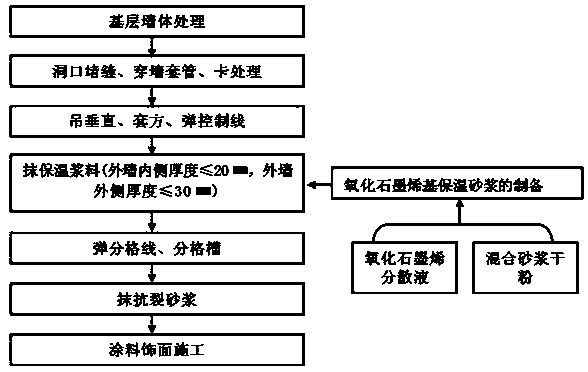

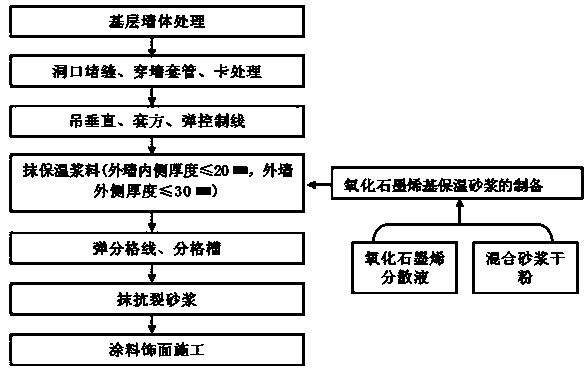

[0032] (1) Base wall treatment: The base wall should be solid, flat, and completely dry without cracking, loosening or pan-alkali, and the protrusions on the wall surface should be removed when the height is greater than 10mm. Ensure that the construction surface is smooth, the bonding strength between the leveling layer and the wall is not less than 0.2MPa, and the leveling layer has no hollows or cracks.

[0033] (2) Door and window opening caulking, wall casing, card processing: door and window frames should be installed in advance, and the area required for thermal insulation construction should be reserved. The downpipes and fire ladders protruding from the wall, the inlet pipelines passing through the wall op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com