Synchronous motion roundness error separation device and method

A roundness error and error separation technology, which is applied in the field of precision instrument manufacturing and measurement, can solve the problems of model principle error, spindle radial rotation error separation error separation of ultra-precision roundness measuring instruments, turntable radial rotation error, and complicated calculation. , to achieve the effect of few calculation steps, fast detection speed and simple calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0045] The following embodiments are embodiments of the present invention based on a synchronous movement type circularity error separation device.

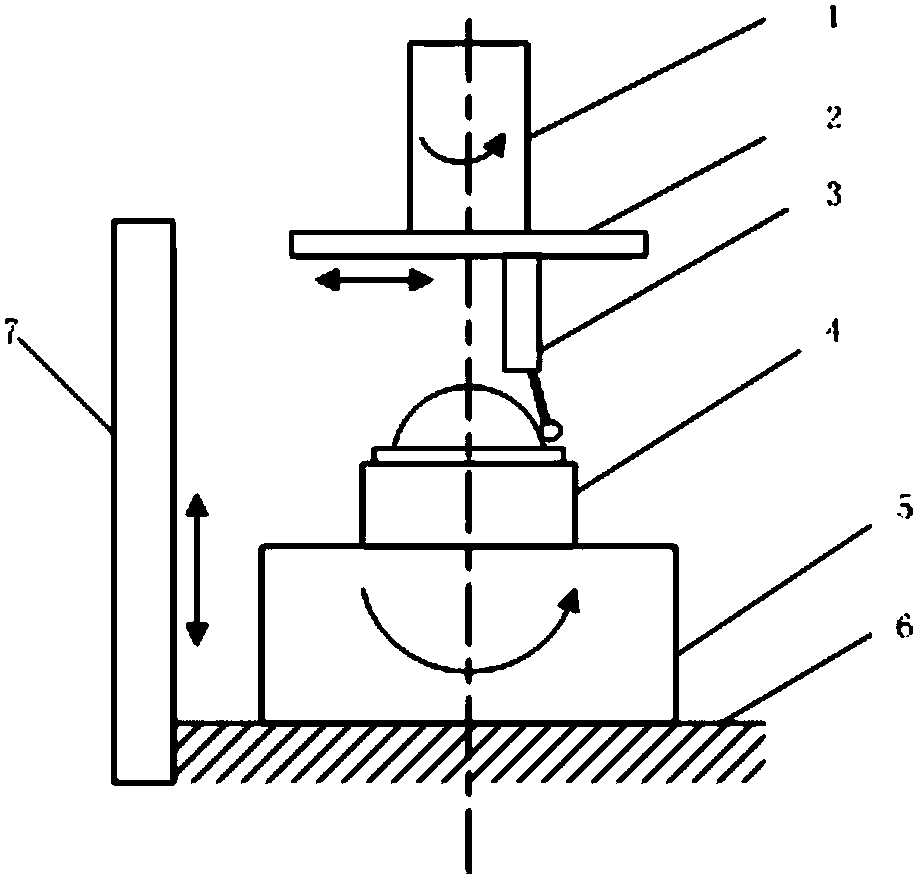

[0046] The roundness error separation device based on synchronous motion in this embodiment is characterized in that it includes a rotary main shaft 1, a lateral guide rail 2, a displacement sensor 3, an error separation turntable 5, a worktable 6 and a vertical guide rail 7, and the rotary main shaft 1 and the lateral The guide rail 2 is connected through the center, the displacement sensor 3 moves horizontally on the transverse guide rail 2, the rotary spindle 1, the transverse guide rail 2 and the displacement sensor 3 move coaxially, the error separation turntable 5 is placed on the workbench 6, and the error separation turntable 5 and The tested piece 4 rotates together, and the workbench 6 drives the error separation turntable 5 to move up and down along the vertical guide rail 7 with the tested piece 4 to find the position ...

specific Embodiment approach 2

[0049] The following embodiments are embodiments of the method for separating roundness errors based on synchronous motion in the present invention.

[0050] The present invention is based on the synchronous movement type circularity error separation method, comprises the following steps:

[0051] Step a, place the error separation turntable 5 on the workbench 6, and roughly adjust the error separation turntable 5 to be concentric with the rotary spindle 1;

[0052] Step b, determine the section to be measured of the tested piece 4, lift the workbench 6 along the vertical guide rail 7, make the section to be tested of the tested piece 4 and the measuring head of the displacement sensor 3 be on the same section, adjust the tested piece 4, so that The section to be measured of the tested part 4 is concentric with the error separation turntable 5;

[0053] Step c. The error separation turntable 5 and the measured piece 4 are regarded as a whole, and the error separation turntabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com