Nickel-chromium-aluminum-iron alloy transmission electron microscope sample preparation method

A technology for transmission electron microscope samples and iron alloys, applied in scanning probe technology, instruments, etc., can solve the problems of coarse grains, good corrosion resistance and lattice distortion of nickel-chromium-aluminum-iron alloys, and achieve uniform thin area and large area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

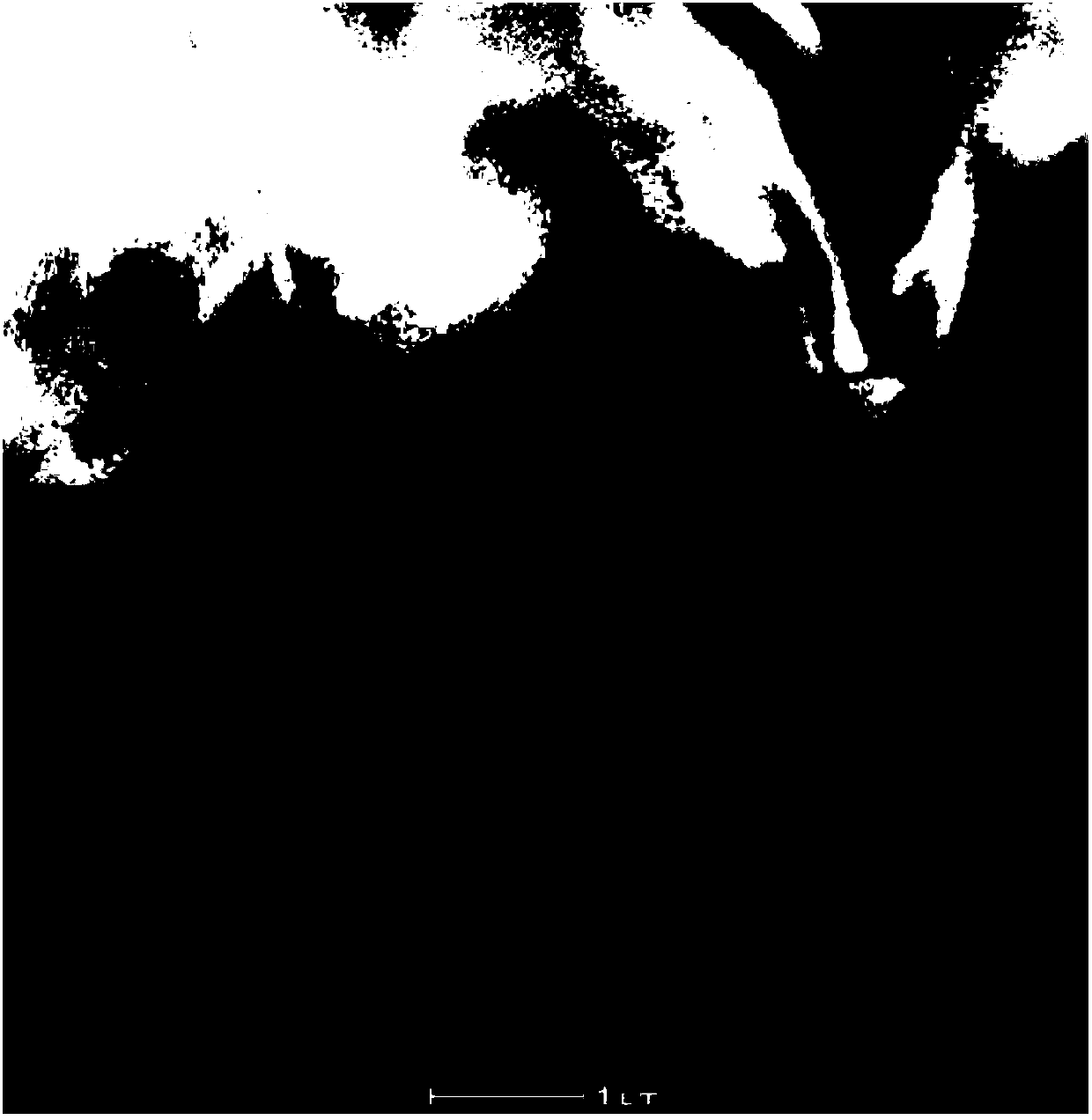

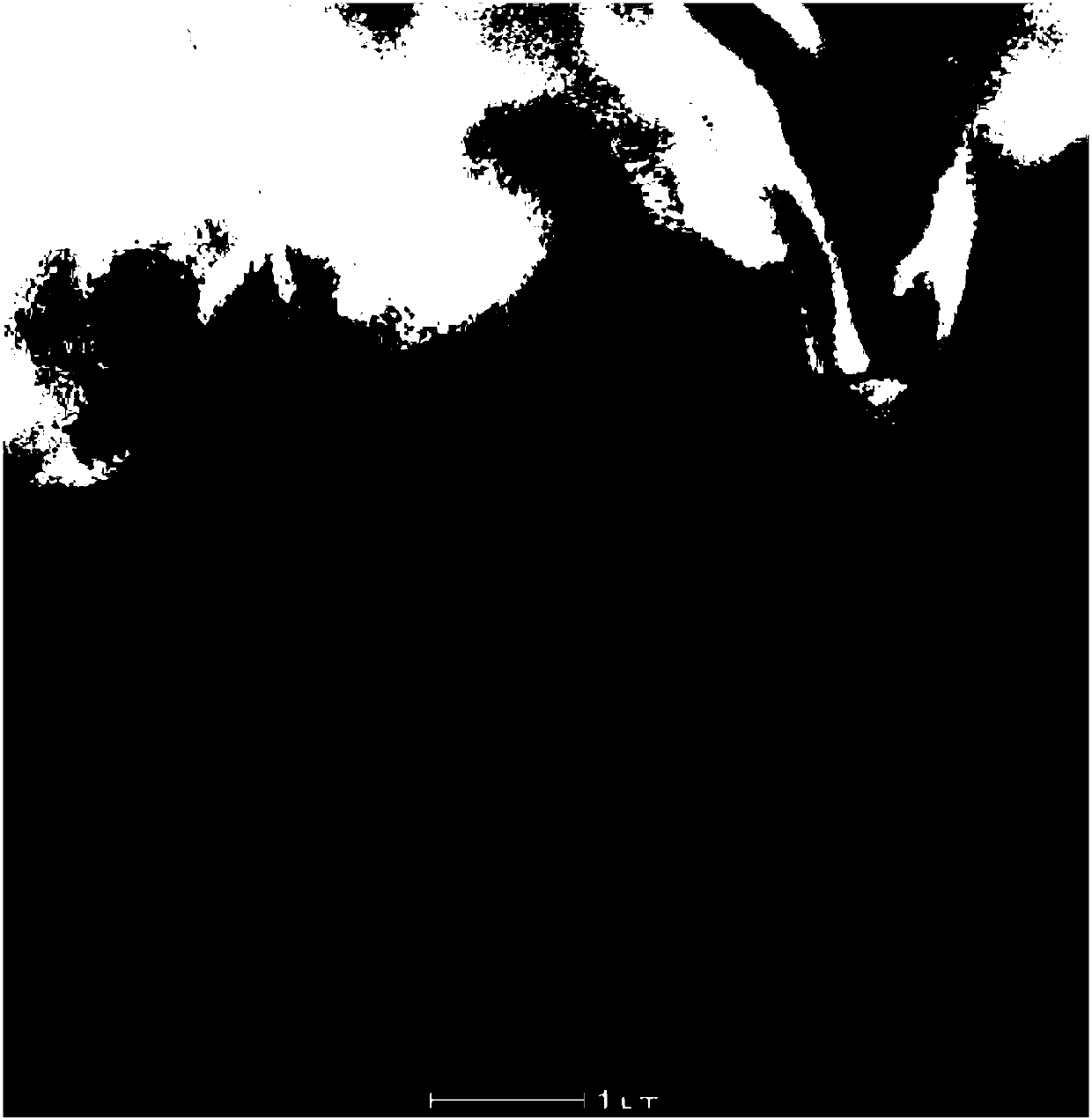

Image

Examples

Embodiment 1

[0037] 1) Cut the sample, cut the nickel-chromium-aluminum-iron alloy sample to a thickness of 1mm by mechanical cutting method.

[0038] 2) Pre-grinding, grind the sample with sandpaper from low to high grades, and grind according to the "8" shape or vertical direction. Pay attention to clean the sandpaper and the sample every time the sandpaper is changed, and finally pre-grind the sample with sandpaper to a thickness of about 45 μm. The final grinding should be done with sandpaper above 800# to ensure that the surface of the pre-ground sample is smooth and free of scratches. crease or bend.

[0039] 3) Slicing: Use a punching machine to punch a disc with a diameter of 3 mm to ensure that there are no burrs on the edge of the punching, and avoid burrs from causing tip discharge or blocking the electron beam.

[0040] 4) Preparation of double-spray solution: prepare a double-spray solution of 10% perchloric acid, 3% citric acid, and 87% absolute ethanol by volume.

[0041] ...

Embodiment 2

[0046] 1) Cutting the sample, cutting the nickel-chromium-aluminum-iron alloy sample to a thickness of 0.8mm by mechanical cutting method.

[0047] 2) Pre-grinding, grind the sample with sandpaper from low to high grades, and grind in the shape of "8" or vertically. Pay attention to clean the sandpaper and the sample every time the sandpaper is changed, and finally pre-grind the sample with sandpaper to a thickness of about 42 μm. The final grinding should be done with sandpaper above 800# to ensure that the surface of the pre-ground sample is smooth and free of scratches. crease or bend.

[0048] 3) Slicing: Use a punching machine to punch a disc with a diameter of 3 mm to ensure that there are no burrs on the edge of the punching, and avoid burrs from causing tip discharge or blocking the electron beam.

[0049] 4) Preparation of double-spray solution: prepare a double-spray solution of 8% perchloric acid, 2% citric acid, and 90% absolute ethanol by volume.

[0050] 5) Ele...

Embodiment 3

[0055] 1) Cutting the sample, cutting the nickel-chromium-aluminum-iron alloy sample to a thickness of 0.5mm by mechanical cutting method.

[0056]2) Pre-grinding, grind the sample with sandpaper from low to high grades, and grind in the shape of "8" or vertically. Pay attention to clean the sandpaper and the sample every time the sandpaper is changed, and finally pre-grind the sample with sandpaper to a thickness of about 40 μm. The final grinding should be done with sandpaper above 800# to ensure that the surface of the pre-ground sample is smooth and free of scratches. crease or bend.

[0057] 3) Slicing: Use a punching machine to punch a disc with a diameter of 3 mm to ensure that there are no burrs on the edge of the punching, and avoid burrs from causing tip discharge or blocking the electron beam.

[0058] 4) Preparation of double-spray solution: Prepare a double-spray solution of 11% perchloric acid, 4% citric acid, and 85% absolute ethanol by volume.

[0059] 5) Ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com