Integrated circuit component assembly type array direct connector

An integrated circuit and direct connector technology, which is applied in the field of verification tools, can solve the problems of increasing design cost and design cycle, difficult to verify integrated circuit components, and not having multiple reuses, and achieves good safety and reusability. properties, excellent electrical conductivity, and the effect of preventing short circuits or electrostatic breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

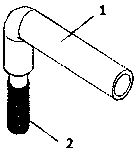

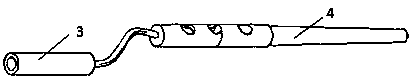

[0016] Such as Figure 6 The connection between the L-shaped upper link and the lower link is used in the actual inspection and verification of the D-shaped component A. The upper section is composed of a pin tube 1 and an external thread connection end 2 as a whole, such as figure 1 , the pin tube 1 forms an "L-shape" in the vertical direction according to the pin insertion; the pin tube 1 of the upper section is a through hole with a diameter of 1.2mm, and the pins of the test sample tube can be directly inserted into it; the main material is copper to ensure that it has Good electrical connectivity, coated with an insulating layer on the outside to prevent short circuits. Such as image 3 , the lower connecting section is composed of the internal thread connection end 3 and the test pin 4. There are three through holes with a diameter of 0.8mm at the upper end of the testing pin of the lower connecting section, which are used for the assembly of resistance and capacitance...

Embodiment 2

[0018] Such as Figure 7 The connection between the I-type upper link and the lower link is used in the actual inspection and verification of the J-type component B. The upper section is composed of a pin tube 1 and an external thread connection end 2 as a whole, such as figure 2 , the pin tube 1 forms an "I shape" in the vertical direction according to the pin insertion; the pin tube 1 of the upper section is a through hole with a diameter of 1.2mm, and the pins of the test sample tube can be directly inserted into it; the main material is copper, to ensure it It has good electrical connectivity and is coated with an insulating layer to prevent short circuits. Next paragraph is the same as embodiment 1.

Embodiment 3

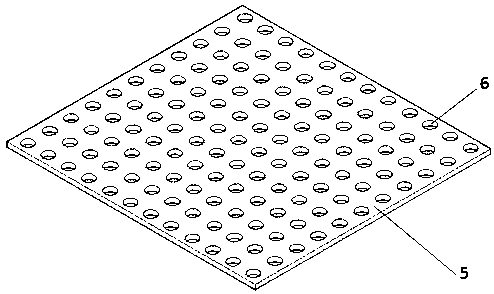

[0020] Such as Figure 5 According to the assembly method of the array direct connector components, the upper and lower segments are respectively screwed into a through hole at the upper end and the lower end of the fixing plate 5, and the externally threaded connecting end 2 is screwed into the internally threaded connecting end 3, that is, fixed and assembled into a The verification unit inserts the pins of the F-type component to be tested and verified directly into the pin tube 1, and then inserts the test pin 4 into the insertion tube of the test board 7, so that the component can be tested and verified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com