Electroplating preparation method of lithium ion battery with reference electrode

A lithium-ion battery and reference electrode technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, and final product manufacturing. It can solve problems such as firm connection between difficult lithium and copper, low lithium content, and electrode loss. Achieve the effect of meeting the requirements of industrial production, simple manufacturing process and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

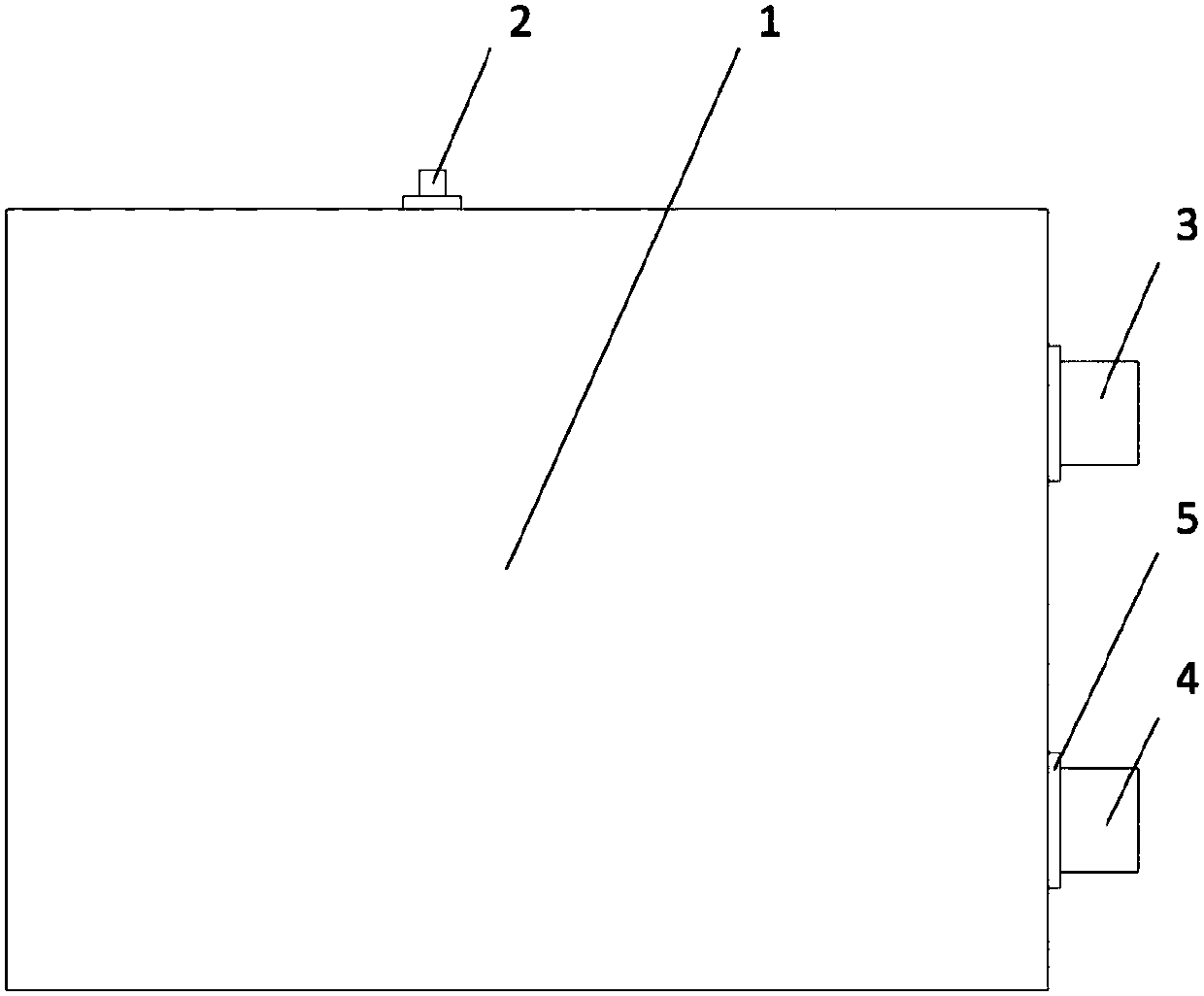

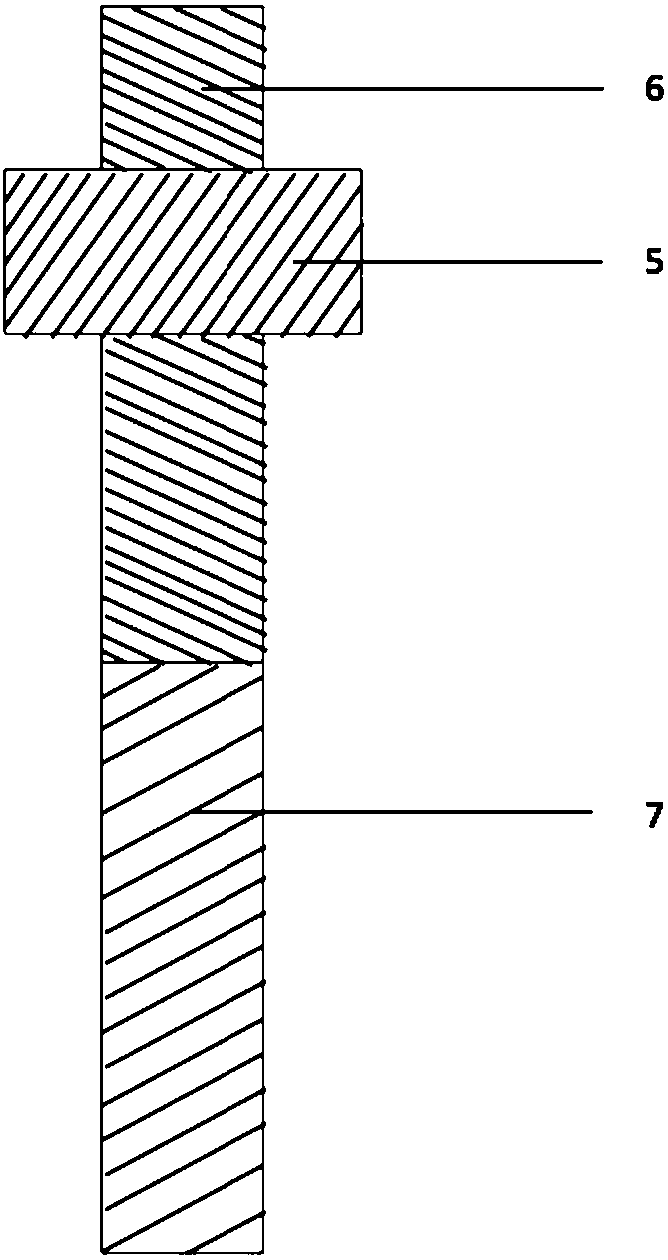

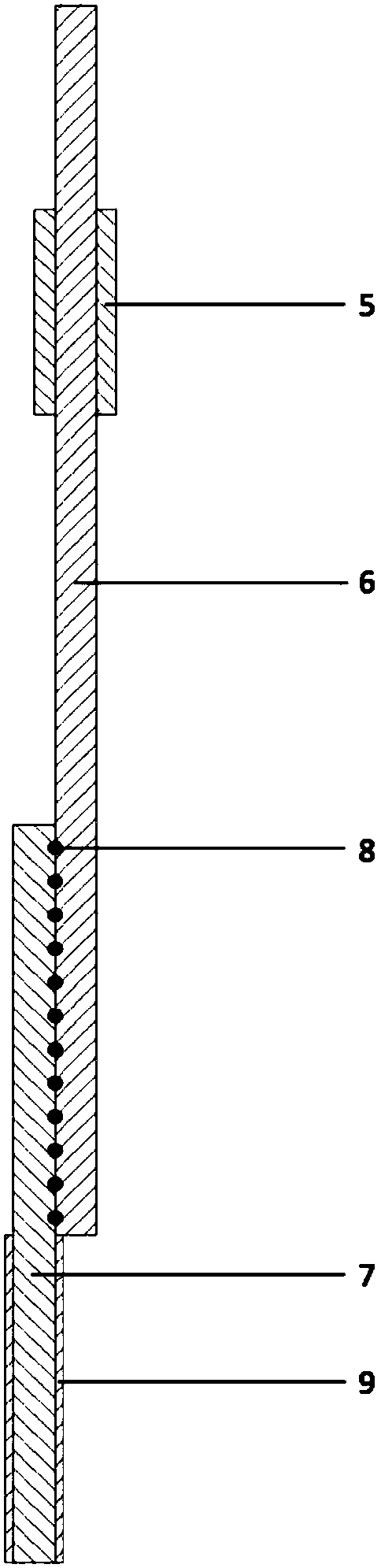

[0027] Its preparation method comprises the following steps:

[0028] (1) Prepare the reference electrode, the specific process is as follows: use porous copper foam, foam nickel, mesh copper or mesh nickel as the substrate of the reference electrode, the pore size of the substrate material is: 50-500 μm, the reference The thickness of the electrode substrate is 0.1-2mm, and the area of the reference electrode substrate is 1%-10% of the area of the pole piece of the lithium ion battery. Clean and dry the reference electrode substrate for later use;

[0029](2) The reference electrode substrate that above-mentioned step (1) obtains is welded to the bottom of the current collector metal sheet that the top is glued with the tab glue, so that the top of the reference electrode substrate and the bottom of the current collector metal sheet overlap each other, The area of the current collector metal sheet is smaller than the area of the substrate; vacuum drying is carried ou...

Embodiment 1

[0036] (1) Prepare the reference electrode, the specific process is as follows: use the mesh nickel with porous structure as the substrate of the reference electrode, the aperture of the substrate material is: 50 μm, the thickness of the reference electrode substrate is: 0.2mm, press Mercury method measurement, the specific surface area of the substrate material with this aperture is 0.04m 2 / g The area of the reference electrode substrate is 1% of the area of the lithium-ion battery pole piece, the size is: a rectangular material piece with a length of 12mm and a width of 7mm, and the mass of the material piece is about 20mg. Wash the reference electrode substrate with deionized water and dry it for later use;

[0037] (2) The reference electrode substrate that above-mentioned step (1) obtains is welded to the bottom of the current collector metal sheet that the top is glued with the tab glue, so that the top of the reference electrode substrate and the bottom of the cu...

Embodiment 2

[0040] (1) Prepare the reference electrode, the specific process is as follows: use porous copper foam as the substrate of the reference electrode, the pore diameter of the substrate material is: 100 μm, the thickness of the reference electrode substrate is: 0.2mm, the reference electrode The area of the substrate is 2% of the area of the pole piece of the lithium ion battery, a rectangular material piece with a length of 10mm and a width of 5mm, and the mass of the material piece is about 55mg. Measured by mercury intrusion porosimetry, the material specific surface area of this pore size is 0.035m 2 / g. Clean the reference electrode substrate with acetone and dry it for later use;

[0041] (2) The reference electrode substrate that above-mentioned step (1) obtains is welded to the bottom of the current collector metal sheet that the top is glued with the tab glue, so that the top of the reference electrode substrate and the bottom of the current collector metal sheet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com