Forming equipment for producing concrete components

A forming equipment and concrete technology, which is applied in the field of 2/1u-shaped, full-u-shaped, rectangular and trapezoidal concrete components, can solve the problem of unsatisfactory product strength, frost resistance, impermeability and service life, technical and Higher operating requirements, affecting product quality and work efficiency, etc., to achieve the effects of good frost resistance and anti-seepage performance, compact structure of the whole machine, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

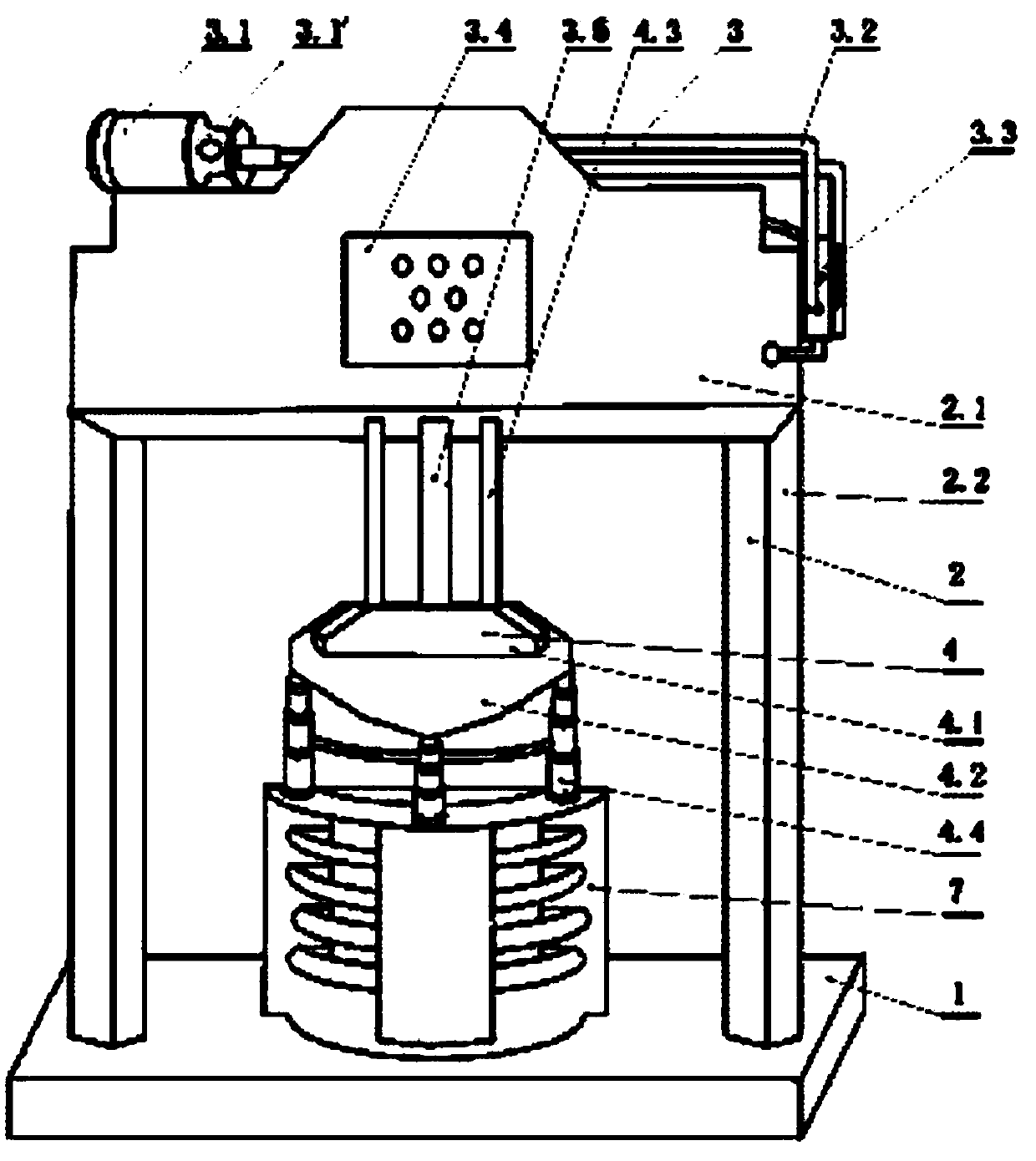

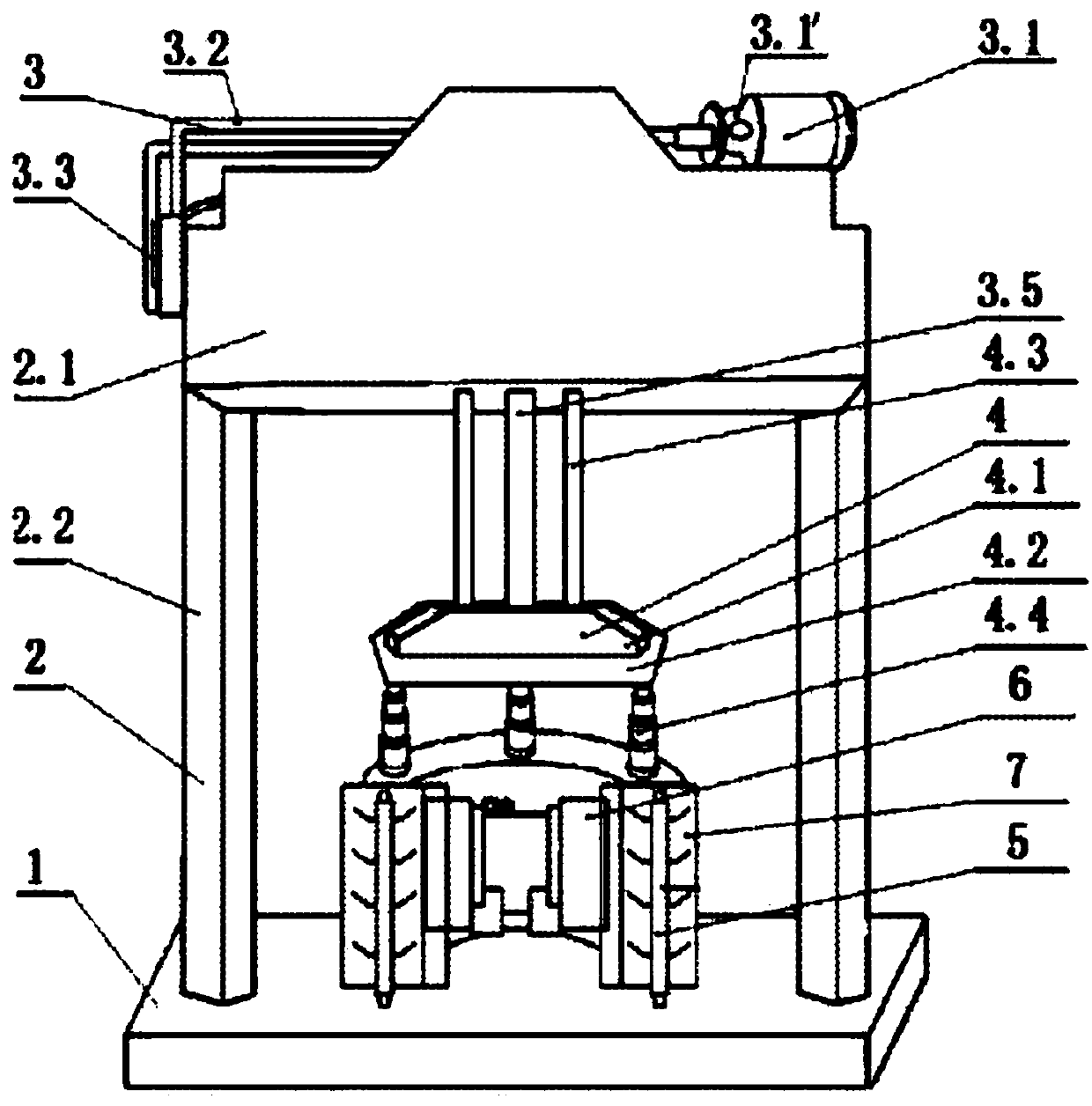

[0020] Such as figure 1 , 2 As shown, a forming equipment for producing concrete components has a machine base 1 and a gantry frame 2 composed of a beam 2.1 and a column 2.2; one includes a hydraulic pump motor 3.1, a hydraulic pump 3.1', a hydraulic oil pipe 3.2, Reversing valve 3.3, electric control box 3.4, and hydraulic system 3 of hydraulic cylinder 3.5; there is also a pressure head system 4 including pressure head seat 4.1, working pressure head 4.2, at least two balance guide rails 4.3, and telescopic rod 4.4 There is only one hydraulic cylinder 3.5, which is vertically installed in the middle of the beam 2.1; the lower end of the hydraulic rod of the hydraulic cylinder 3.5 is fixedly connected to the pressure head seat 4.1; the lower end of the balance guide rail 4.3 is fixedly connected to the pressure head seat 4.1, and the balance guide rail 4.3 The upper part is slidingly matched with the guide member fixed in the beam 2.1. The balance guide rail 4.3 is parallel ...

Embodiment 2

[0022] The difference from the above-mentioned embodiment 1 is that the balance guide rail 4.3 is evenly distributed on the outside of the hydraulic rod of the hydraulic cylinder 3.5, and there are three balance guide rails 4.3; , it can also be suspended on the column 2.2 or the beam 2.1; the concrete mold 7 is rectangular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com