Trivalent cation viscoelastic surfactant, and preparation method and application thereof as well as clean fracturing fluid

A surfactant and clean fracturing fluid technology, which is applied in the preparation of carboxylic acid amide, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problems of poor high temperature resistance, complicated preparation process, high production cost, etc., and achieve performance impact Small size, simple preparation, and the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation method of the triple cationic viscoelastic surfactant of the present embodiment is as follows:

[0054] Add 60mmol of N,N'-dimethyl-1,3-propanediamine into a round bottom flask, use ethanol as solvent, add 200mmol of epichlorohydrin and 60mmol of concentrated hydrochloric acid, reflux at 60°C for 6 hours, and react After the end, the intermediate A was obtained by distillation and extraction under reduced pressure. Dissolve the obtained intermediate A in ethanol, add 180 mmol of erucamide propyl dimethylamine, and reflux for 12 hours at 85°C and 250 r / min. After the reaction, the solvent ethanol is distilled off under reduced pressure to obtain a light yellow viscous Liquid, that is, triad cationic viscoelastic surfactants.

[0055] The critical micelle concentration of the tensio-active agent of the present embodiment is 1.44 * 10 -4 mol / L.

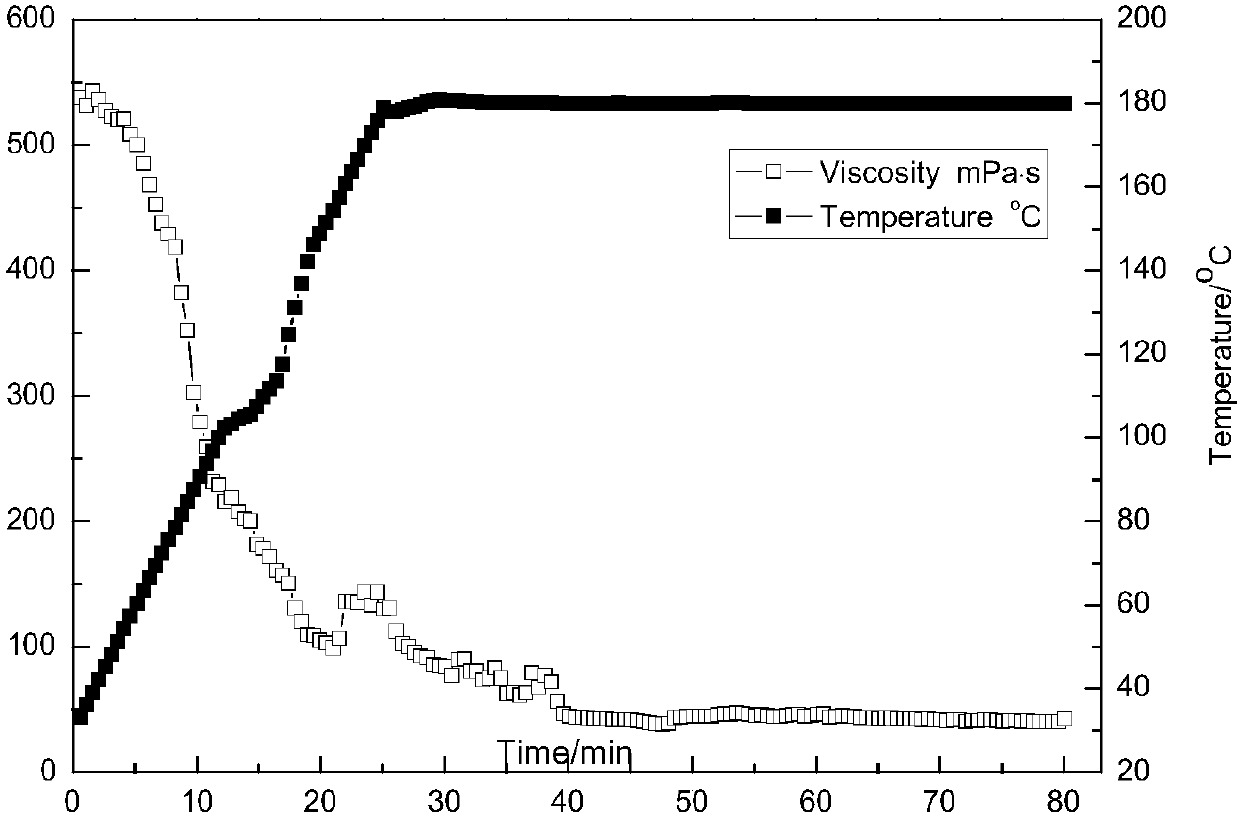

[0056] The clean fracturing fluid prepared by 3% Sanzi cationic viscoelastic surfactant + 1.2% sodium salicyl...

Embodiment 2

[0058] The preparation method of the triple cationic viscoelastic surfactant of the present embodiment is as follows:

[0059] Add 60mmol of N,N'-dimethyl-1,3-propanediamine into a round bottom flask, use ethanol as solvent, add 200mmol of epichlorohydrin and 60mmol of concentrated hydrochloric acid, reflux at 60°C for 6 hours, and react After the end, the intermediate A was obtained by distillation and extraction under reduced pressure. Dissolve the obtained intermediate A in ethanol, add 180 mmol of oleic acid amidopropyl dimethylamine, and reflux for 12 hours at 85°C and 270 r / min. After the reaction is completed, the solvent ethanol is distilled off under reduced pressure to obtain a light yellow viscous Liquid, that is, triad cationic viscoelastic surfactants.

[0060] The critical micelle concentration of the tensio-active agent of the present embodiment is 1.56 * 10 -4 mol / L.

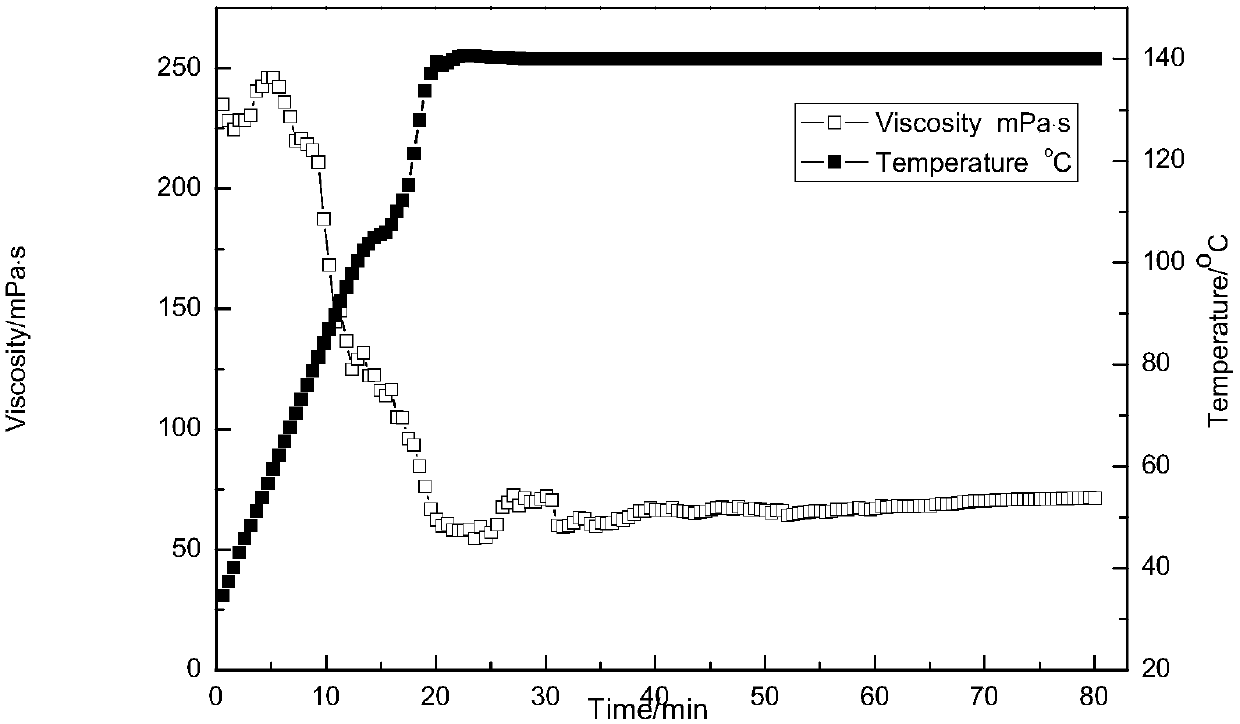

[0061] The clean fracturing fluid prepared by 3% Sanzi cationic viscoelastic surfactant + ...

Embodiment 3

[0063] The preparation method of the triple cationic viscoelastic surfactant of the present embodiment is as follows:

[0064] Add 60mmol of N,N'-dimethyl-1,3-propanediamine into a round bottom flask, use ethanol as solvent, add 200mmol of epichlorohydrin and 60mmol of concentrated hydrochloric acid, reflux at 60°C for 6 hours, and react After the end, the intermediate A was obtained by distillation and extraction under reduced pressure. Dissolve the obtained intermediate A with ethanol, add 180 mmol of stearic acid amidopropyl dimethylamine, and reflux for 12 hours at 85°C and 280 r / min. After the reaction is completed, the solvent ethanol is distilled off under reduced pressure to obtain a light yellow viscous Viscous liquid, that is, triad cationic viscoelastic surfactant.

[0065] The critical micelle concentration of the tensio-active agent of the present embodiment is 1.84 * 10 -4 mol / L.

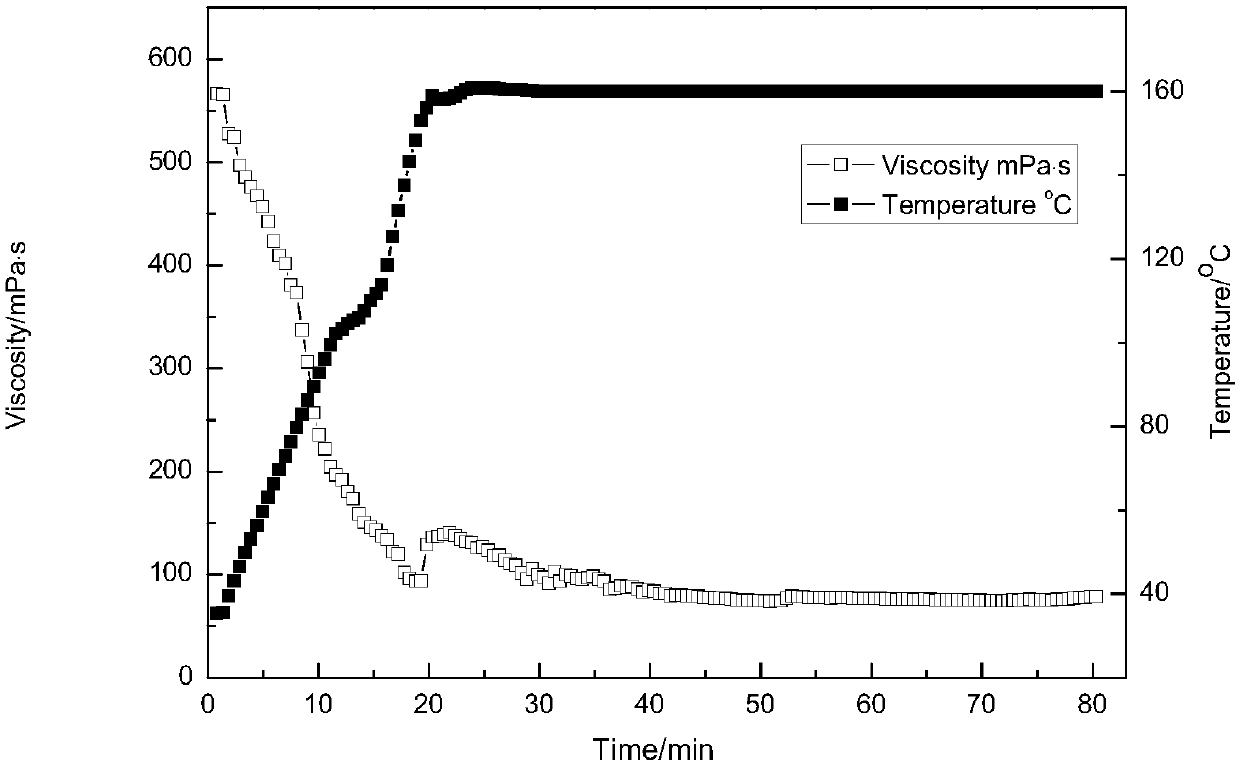

[0066] The clean fracturing fluid prepared by 3% Sanzi cationic viscoelastic su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaker viscosity | aaaaa | aaaaa |

| Breaker viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com