Thianthrene oxide-based yttrium complex phosphorescent luminescent materials and preparation methods thereof

A phosphorescent luminescent material, thianthrene oxide technology, applied in luminescent materials, indium organic compounds, platinum group organic compounds, etc., can solve the problems of weak electron injection and transmission capabilities and low quantum efficiency, and achieve enhanced electron injection and transmission capabilities, The effect of increasing the value of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

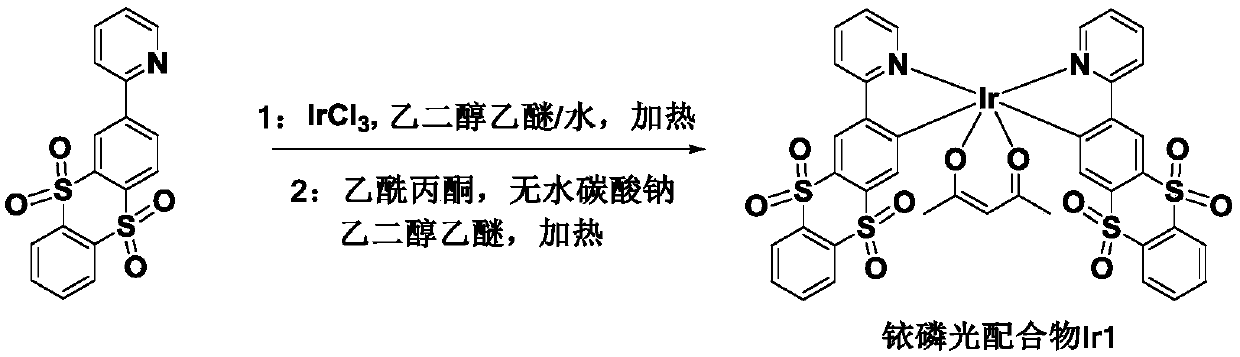

[0027] The organometallic iridium complex phosphorescent material Ir1 of the present embodiment has a chemical formula of C 39 h 27 IrN 2 o 10 S 4 , the molecular structure formula is:

[0028]

[0029] Refer to attached figure 1 , the synthesis steps are as follows:

[0030] The first step: 0.78mmol organic ligand Put 0.39mmol iridium trichloride into the reaction vessel, add 30mL of a mixed solvent of ethylene glycol ether and water in a nitrogen atmosphere, the volume ratio of ethylene glycol ether and water in the mixed solvent is 3:1, and heat to 110 in a nitrogen atmosphere ℃, stirred for 12 hours and then cooled to room temperature, resulting in precipitation;

[0031] Step 2: Add 50 mL of deionized water to the final reaction mixture in Step 1 to generate a precipitate, which is obtained by suction filtration and dried in a vacuum oven. Then the precipitate was mixed with 3.9mmol acetylacetone and 7.8mmol anhydrous sodium carbonate, 20mL of ethylene glycol ...

Embodiment 2

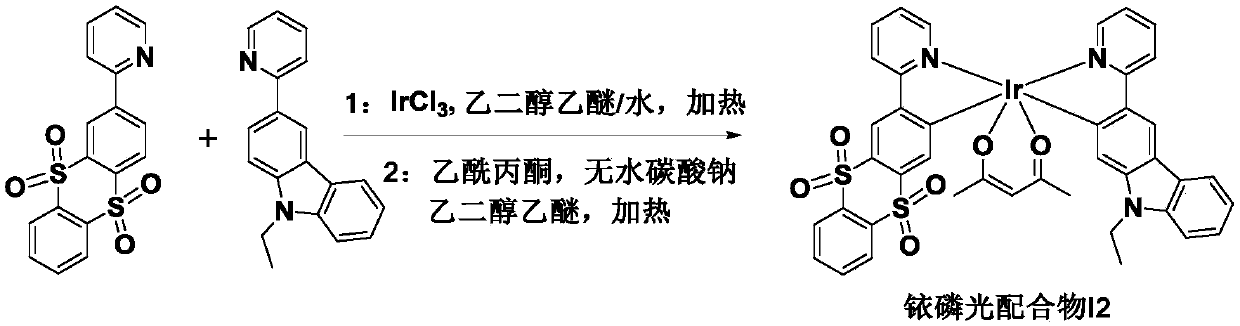

[0035] The organometallic iridium complex phosphorescent material Ir2 of the present embodiment has a chemical formula of C 41 h 32 IrN 3 o 6 S 2 , the molecular structure formula is:

[0036]

[0037] Refer to attached figure 2 , the synthesis steps are as follows:

[0038] The first step: 0.24mmol organic ligand With 0.24mmol organic ligand And 0.24mmol iridium trichloride is put into the reaction vessel, add the mixed solvent of 30mL ethylene glycol ether and water in nitrogen atmosphere, the volume ratio of ethylene glycol ether and water in the mixed solvent is 3:1, heat to 110 in nitrogen atmosphere ℃, stirred for 12 hours and then cooled to room temperature, resulting in precipitation;

[0039]Step 2: Add 50 mL of deionized water to the final reaction mixture in Step 1 to generate a precipitate, which is obtained by suction filtration and dried in a vacuum oven. Then the precipitate was mixed with 2.4 mmol acetylacetone and 4.8 mmol anhydrous sodium carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com