Charcoal fire high temperature-resistant powdery coating special for barbecues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

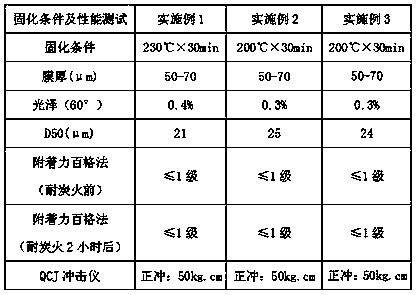

Image

Examples

Embodiment 1

[0041] A special charcoal fire-resistant high-temperature powder coating for barbecue grills, consisting of the following components by weight percentage:

[0042] Epoxy 20%

[0043] High temperature resistant material 25%

[0044] Matting agent 1%

[0045] Leveling agent 1%

[0046] Charge enhancer 0.4%

[0047] Extinct Barium 40.6%

[0048] High temperature black 12%.

[0049] In one embodiment, the epoxy resin is a two-step epoxy resin with a softening point of 90°C and a viscosity of 38Pa at 150°C. s, the epoxy equivalent is 760g / eq.

[0050] In one embodiment, the high-temperature-resistant material is a mixture of any two or more of silicone intermediates, high-temperature fillers and coupling agents.

[0051] In one embodiment, the matting agent is an indoor chemical matting curing agent.

[0052] In one embodiment, the leveling agent is a leveling agent that can increase the interlayer adhesion between the powder and the substrate, and the leveling agent is an ...

Embodiment 2

[0056] A special charcoal fire-resistant high-temperature powder coating for barbecue grills, consisting of the following components by weight percentage:

[0057] Epoxy 21%

[0058] High temperature resistant material 24%

[0059] Matting agent 2%

[0060] Leveling agent 1.5%

[0061] Charge enhancer 0.5%

[0062] Dull Barium 36%

[0063] High temperature black 15%.

[0064] In one embodiment, the epoxy resin is a two-step epoxy resin with a softening point of 94°C and a viscosity of 41Pa at 150°C. s, the epoxy equivalent is 780g / eq.

[0065] In one embodiment, the high-temperature-resistant material is a mixture of any two or more of silicone intermediates, high-temperature fillers and coupling agents.

[0066] In one embodiment, the matting agent is an indoor chemical matting curing agent.

[0067] In one embodiment, the leveling agent is a leveling agent that can increase the interlayer adhesion between the powder and the substrate, and the leveling agent is an acr...

Embodiment 3

[0071] A special charcoal fire-resistant high-temperature powder coating for barbecue grills, consisting of the following components by weight percentage:

[0072] Epoxy 19%

[0073] High temperature resistant material 25%

[0074] Matting agent 2%

[0075] Leveling agent 2%

[0076] Charge enhancer 0.5%

[0077] Dull barium 37.5%

[0078] High temperature black 14%.

[0079] In one of the embodiments, the epoxy resin is a two-step epoxy resin, the softening point is 96°C, and the viscosity at 150°C is 44Pa. s, the epoxy equivalent is 800g / eq.

[0080]In one embodiment, the high-temperature-resistant material is a mixture of any two or more of silicone intermediates, high-temperature fillers and coupling agents.

[0081] In one embodiment, the matting agent is an indoor chemical matting curing agent.

[0082] In one embodiment, the leveling agent is a leveling agent that can increase the interlayer adhesion between the powder and the substrate, and the leveling agent i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com