Preparation method of safety glass

A safety glass, glass technology, applied in chemical instruments and methods, glass/slag layered products, lamination, etc., can solve problems such as damage to the service life of profiles, glass self-cracking, etc., to achieve convenient installation, excellent thermal insulation performance, difficult Excellent combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

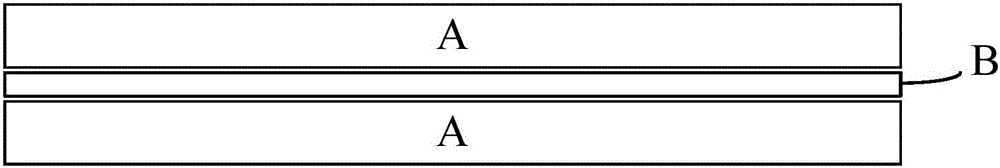

[0061] A polycarbonate plate is used as the first material layer (A), and a polyurethane film is used as the adhesive layer (B). This embodiment provides a method for preparing safety glass with an ABA structure, specifically comprising the following steps:

[0062] S11: Lay polycarbonate boards and polyurethane boards together in the order of ABA, and then heat to 90°C for softening. The heating time is 20 minutes to preliminarily compound polycarbonate and polyurethane to obtain a mixed material.

[0063] S12: Then, put the mixed material into the autoclave, increase the pressure to 0.2MPa, and raise the temperature to 110°C. At this stage, the polycarbonate sheet begins to soften further and interacts with polyurethane molecules to produce crosslinks.

[0064] S13: After the above heating and pressurization, continue to increase the pressure of the autoclave to 1.2 MPa and the temperature to 130°C. At this stage, sufficient chemical crosslinking occurs between polycarbona...

Embodiment 2

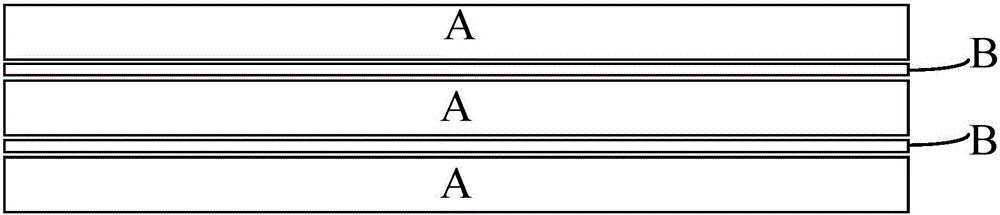

[0067] A polycarbonate plate is used as the first material layer (A), and a polyurethane film is used as the adhesive layer (B). The present embodiment provides a kind of preparation method of the safety glass of ABABA structure, specifically comprises the following steps:

[0068] S21: The polycarbonate board and the polyurethane board are stacked together in the order of ABABA, and then heated to 100° C. for softening. The heating time is 10 minutes, so that the polycarbonate and polyurethane are preliminarily compounded to obtain a mixed material.

[0069] S22: Acting the mixed material in an environment with a pressure of 1 MPa and a temperature of 120° C. for 3 hours.

[0070] S23: Increase the pressure of the environment to 2 MPa and the temperature to 130° C., and act on the mixed material in the previous step for 4 hours in this environment. The pressure and temperature of the environment are then reduced to normal temperature and pressure.

[0071] Note: The thickne...

Embodiment 3

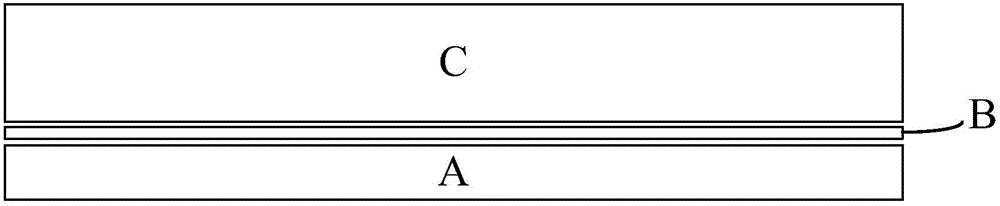

[0073] In this embodiment, a layer of inorganic silicate glass is added to the raw materials used, and the inorganic silicate glass layer is used as the second material layer (C), and the polycarbonate plate is continued to be used as the first material layer (A) 1. Polyurethane film is used as the adhesive layer (B) to prepare safety glass with CBA structure. Specifically include the following steps:

[0074] S31: The inorganic silicate glass, the polycarbonate plate and the polyurethane film are stacked together in the order of CBA, and then heated and softened to obtain a mixed material. In this embodiment, the heating temperature is 90° C., and the heating time is 15 minutes.

[0075] S32: Acting the mixed material in an environment with a pressure of 0.6 MPa and a temperature of 130° C. for 2 hours.

[0076] S33: Increase the pressure of the environment to 1.2 MPa, and maintain the temperature at 130° C., and act on the mixed material in the previous step for 3 hours in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com