Deeply curable, transparent two-component condensation type silicone adhesive and preparation method thereof

An organic silica gel, condensation-type technology, used in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of substrate corrosion, transparency and deep curing properties difficult to meet application requirements at the same time, heavy metal excess, etc. To achieve the effect of meeting application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

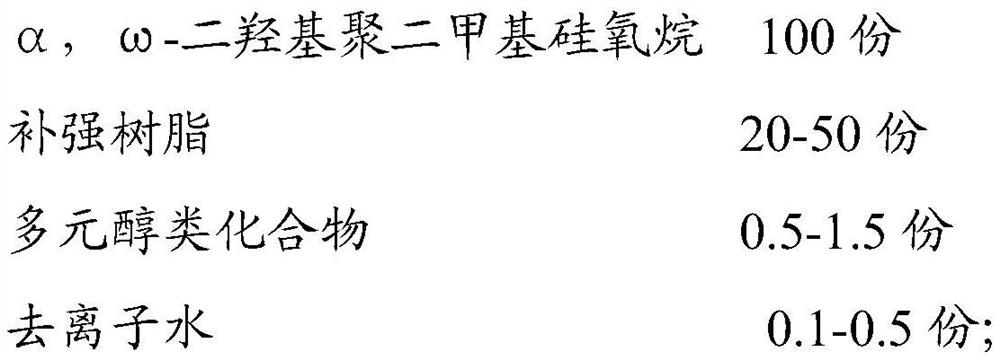

[0035] The two-component condensation type silicone adhesive in this embodiment is composed of A component and B component.

[0036] Component A is prepared from the following raw materials: 100 parts of 500cps α, ω-dihydroxy polydimethylsiloxane (107 glue), 45 parts of methyl silicone resin, 0.5 parts of diethylene glycol, 0.5 parts of l,6- Hexylene glycol, 0.2 parts deionized water.

[0037] The preparation method of component A is as follows: use a high-speed disperser for production. The specific process is to slowly add the reinforcing resin to the 107 glue under high-speed stirring at 950rpm. After the two are thoroughly stirred evenly, add the pre-mixed polyol Slowly add the mixture of quasi-compound and deionized water, continue stirring at 950rpm to disperse at a high speed, and at the same time vacuumize, reach above -0.095MPa within 1min and keep it for 10min, discharge and store in a sealed container.

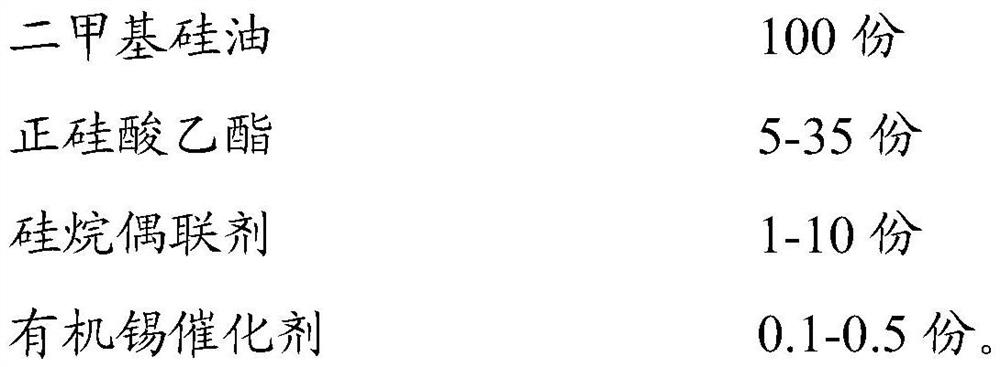

[0038] Component B is prepared from the following raw materia...

Embodiment 2

[0042] The two-component condensation type silicone adhesive in this embodiment is composed of A component and B component.

[0043] Component A is prepared from the following raw materials: 100 parts of 100cps α, ω-dihydroxy polydimethylsiloxane, 25 parts of methyl silicone resin, 0.55 parts of diethylene glycol, 0.2 parts of glycerin, 0.2 parts of deionized water.

[0044] The preparation method of A component is with embodiment 1.

[0045] Component B is prepared from the following raw materials: 100 parts of 50cps dimethyl silicone oil, 10 parts of ethyl orthosilicate, 4 parts of KH550 silane coupling agent, and 0.2 parts of dibutyltin diacetylacetonate.

[0046] The preparation method of B component is the same as embodiment 1.

[0047] When using, take A component and B component with a mass ratio of 10:1 and mix them well.

Embodiment 3

[0049] The two-component condensation type silicone adhesive in this embodiment is composed of A component and B component.

[0050] Component A was prepared from the following raw materials: 100 parts of 200 cps α, ω-dihydroxypolydimethylsiloxane, 40 parts of vinyl silicone resin, 1.15 parts of diethylene glycol, 0.1 part of pentaerythritol, and 0.3 part of deionized water.

[0051] The preparation method of A component is with embodiment 1.

[0052] Component B is prepared from the following raw materials: 100 parts of 75cps dimethicone, 20 parts of ethyl orthosilicate, 3 parts of KH550 silane coupling agent, and 0.3 parts of dibutyltin diacetoacetate.

[0053] The preparation method of B component is the same as embodiment 1.

[0054] When using, take A component and B component with a mass ratio of 10:1 and mix them well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com